What are the common processes for epoxy resin floor paint?

2024-02-20

Let's take a look at the common processes for epoxy resin floor paint together.

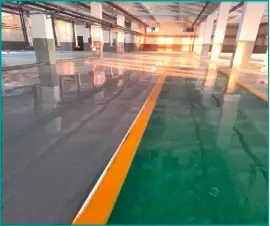

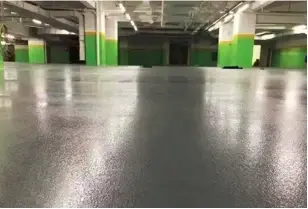

1. Smooth Coating Flooring

Economical, mature technology, suitable for medium and above loads.

01 Applicable areas: heavy-duty industrial plants such as electronics, electrical appliances, machinery, chemicals, pharmaceuticals, textiles, clothing, tobacco, warehouses, damp areas, parking lots, and other special places with cement or terrazzo floors; decoration of dust-free walls and ceilings with purification requirements.

02 Performance characteristics: Smooth and attractive appearance, diverse colors; easy to clean, convenient maintenance; strong adhesion, good flexibility, impact resistance; excellent wear resistance; convenient construction, cost-effective, etc.

2. Mortar Flooring

Suitable for heavy-duty areas, pressure-resistant, impact-resistant, long service life.

01 Applicable areas: floors of supermarkets, lobbies, warehouses, automobile exhibition halls, automobile repair shops, and parking lots; areas with high mechanical performance requirements in mechanical, electronic, instrument, pharmaceutical, textile, clothing, food, tobacco, and other enterprise plants with certain impact requirements.

02 Performance characteristics: Impact-resistant, pressure-resistant, excellent mechanical performance; dustproof, mildew resistant, wear-resistant, good hardness; minimal shrinkage after curing, no cracks; resistant to water, oil stains, acids, alkalis, and general chemical corrosion; smooth and attractive appearance, diverse colors; seamless, easy to clean, convenient maintenance.

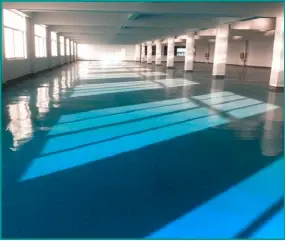

3. Self-leveling Flooring

Can be used for medium and above loads, with a smooth surface, suitable for purification environments.

01 Applicable areas: dust-free and sterile high-specialized places such as aerospace, aviation; GMP pharmaceutical plants, hospitals, blood product dust-free rooms, precision machinery, microelectronics manufacturing plants, areas with high comprehensive performance requirements in mechanical and chemical fields.

02 Performance characteristics: Smooth, beautiful surface with a mirror effect; solvent-free, odorless, non-polluting, non-toxic; acid and alkali resistance, chemical resistance; good resistance to moisture, salt spray, oil, and organic solvents; wear-resistant, pressure-resistant, impact-resistant, heat-resistant, waterproof, with a certain degree of elasticity; one-time molding of the surface layer, quick and convenient construction.

4. Anti-slip (orange peel) Flooring

High pressure and impact resistance, can withstand certain corrosion, and has anti-slip properties.

01 Applicable areas: production workshops of garages, supermarkets, warehouses, automobile repair shops, machinery, docks, food, pharmaceuticals, chemicals, tobacco, feed, textiles, clothing, furniture, and hardware factories; cement-based surfaces, terrazzo-based surfaces in areas with slip resistance requirements such as restaurants, canteens, and water or oil-containing work areas; conference venues, walkways, and purification areas.

02 Performance characteristics: Dustproof, moisture-proof, anti-slip, wear-resistant; strong adhesion, good flexibility, impact resistance; resistance to acid, alkali, salt, and oil corrosion; easy to clean, quick construction, convenient maintenance.

5. Epoxy Microbead Flooring

Hardness above 3H, suitable for heavily worn surfaces.

01 Applicable areas: places requiring cleanliness, aesthetics, wear resistance, and resistance to chemical corrosion such as chemical plants, GMP pharmaceutical plants, electronics plants, standard power plants, office buildings, tobacco plants, food plants, chemical laboratories, parking lots, warehouses, schools, and hospitals.

02 Performance characteristics: Matte paint film, economical usage, simple construction; extremely high hardness, above 3H, micro-rough anti-slip effect, excellent wear resistance; excellent adhesion, good flexibility, impact resistance; dustproof, stain-resistant, seamless, easy to clean.

6. Epoxy Ultra-Wear-Resistant Flooring

Hardness above 4H, suitable for heavily worn surfaces.

01 Applicable areas: floors of supermarkets, lobbies, warehouses, automobile exhibition halls, automobile repair shops, and parking lots; areas with high mechanical performance requirements in mechanical, electronic, electrical, instrumentation, pharmaceutical, textile, clothing, food, and tobacco enterprises.

02 Performance characteristics: Uniform fine particle size on the surface, minimal undulation, high resistance, good anti-slip performance; reasonable structure, stable and comfortable with no vibration and low noise, aesthetically pleasing and anti-slip; pressure-resistant, wear-resistant, impact-resistant, long service life; strong bonding with the base, seamless surface, not easily peeling or cracking; good drainage performance, without debris accumulation, reducing or eliminating splashing and water film, increasing driving safety in rainy weather.

7. Anti-Vibration Anti-Slip Ramp

Excellent anti-slip performance, stable and vibration-free, noise-free, good drainage, non-cracking.

01 Applicable areas: garage ramps, roads, bus lanes, bicycle lanes, sidewalks, and other areas with special anti-slip requirements.

02 Performance characteristics: Excellent anti-slip performance, stable and vibration-free, noise-free; wear-resistant, impact-resistant, pressure-resistant, effectively extending the service life of roads; seamless surface, not prone to cracking or peeling; prominent safety features, strong guidance; good drainage performance, no water accumulation; good resistance to low temperatures, heat, and aging.

8. Water-Based Epoxy Flooring

Environmentally friendly, strong air permeability, suitable for moderately humid surfaces, with a completely matte effect.

01 Applicable areas: floors of clothing, tobacco, and food industry plants; ground floors below the first floor (including basements) with water vapor, seepage, and dampness, such as supermarkets, parking lots, canteens, warehouses, and other special places (construction must ensure that the ground is free of visible water).

02 Performance characteristics: Wear-resistant, good hardness; environmentally friendly, dustproof, mildew resistant; seamless, easy to clean; resistant to water, oil stains, acids, alkalis, and general chemical corrosion; curing performance is less affected by temperature and humidity, with good bonding strength on wet surfaces.

9. Water-Based Polyurethane Matte Flooring

Can achieve 30% matte gloss.

01 Applicable areas: suitable for clean, aesthetically pleasing, wear-resistant, and chemically resistant places such as chemical plants, GMP-standard pharmaceutical plants, electronics plants, standard power plants, office buildings, tobacco plants, food plants, chemical laboratories, parking lots, warehouses, schools, and hospitals.

02 Performance characteristics: Matte paint film, economical usage, simple construction; excellent adhesion, good flexibility, impact and wear resistance; dustproof, stain-resistant, seamless, easy to clean.

10. Epoxy Self-Leveling Corrosion-Resistant Flooring

Can withstand common acid and alkali concentrations of 60%, while also having the aesthetic appeal of epoxy.

01 Applicable areas: long-term corrosion protection for light industrial products, storage tanks, marine equipment, conveying pipelines, electroplating, electrolytic tanks, and other areas; cement floors requiring enhanced mechanical strength or those resistant to strong acid, strong alkali chemical solvent corrosion, surface layers of drainage ditches, alkali water pools.

02 Performance characteristics: Resistant to strong acid, strong alkali; strong adhesion, tear resistance; improves thermal deformation temperature and reduces temperature impact strength; particularly enhances the strength and elasticity of the substrate; possesses all the excellent properties of epoxy self-leveling.

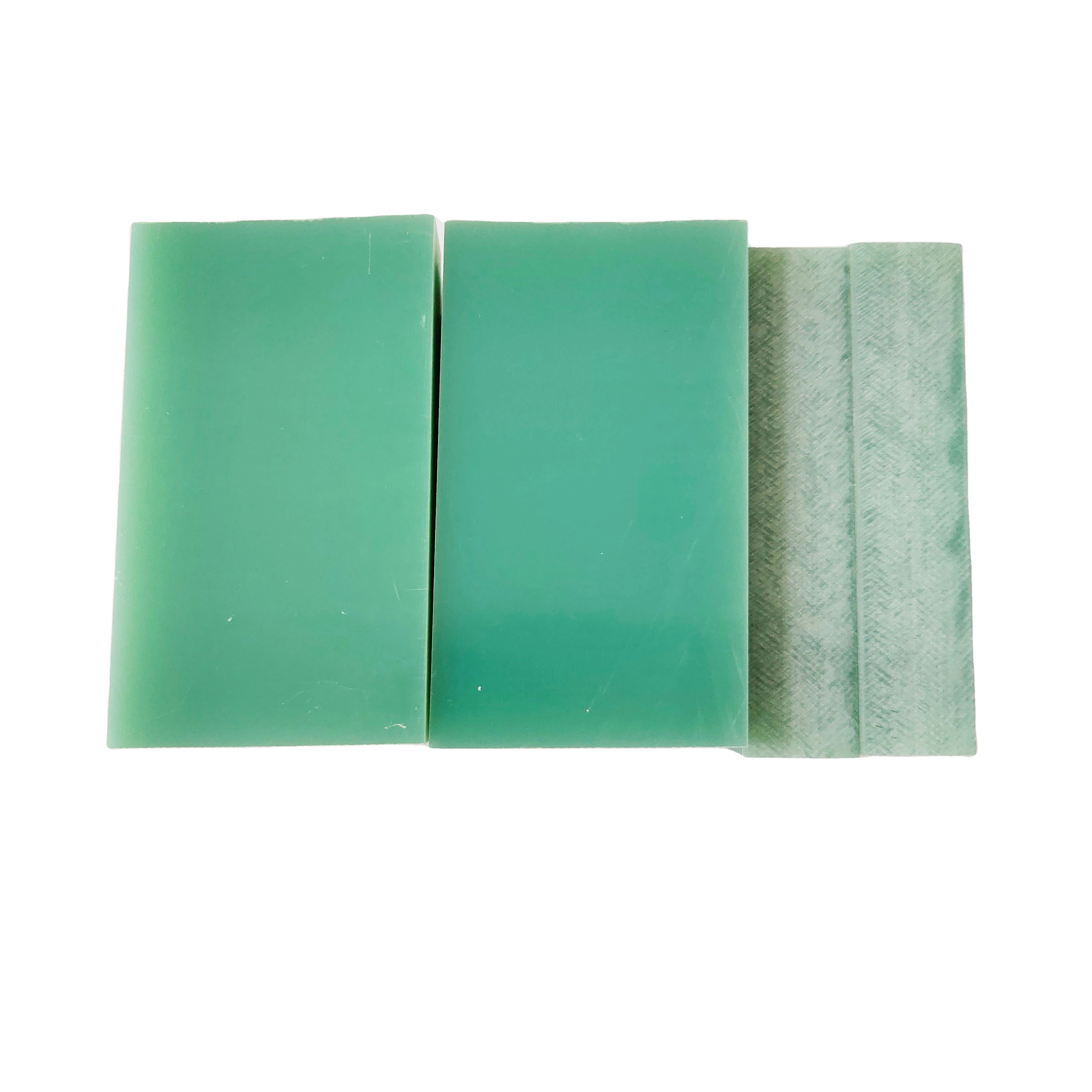

11. Vinyl-based Heavy Corrosion-Resistant Flooring

Resistant to high temperatures, fatigue, excellent mechanical properties and toughness, can resist most chemical reagents such as acids, alkalis, and salts.

01 Applicable areas: widely used for pre-coated steel or concrete surface coatings, especially various mechanical equipment and facilities in the chemical industry environment; can also be used as the substrate for fiberglass; suitable for high-temperature environments below 200°C; suitable for surfaces or mortar surfaces, bulk material surfaces, and ground and isolation layers resistant to strong acid, strong alkali, salt, and other chemical solvent corrosion; suitable for chemical plants, electronic, electroplating, smelting, and other industrial plants.

02 Performance characteristics: Resistant to high temperatures, fatigue, excellent mechanical properties and toughness; freely adjustable curing time, viscosity, easy to apply; can resist most chemical reagents such as acids, alkalis, salts, etc., below 1000 degrees; low-temperature curing, service life can exceed 10 years.

12. Anti-Static Self-Leveling Flooring

Has higher cleanliness performance than ordinary types, indispensable for pharmaceutical and electronic plant floors.

01 Applicable areas: floor systems of chemical, powder, organic solvent production, operating rooms, machine rooms, and special places; floor systems of computer, electronic, microelectronic, precision instrument manufacturing, precision machinery manufacturing, telecommunications, communications, printing, military, aerospace, and other industrial plants.

02 Performance characteristics: Lasting anti-static effect; rapid discharge of static electricity; possesses all the excellent properties of epoxy self-leveling flooring.

13. Anti-Static Smooth Coating Flooring

Stable and lasting surface and system resistance, meeting anti-static standard requirements.

01 Applicable areas: walls and floors requiring anti-static properties, such as chemical, powder, machine rooms, control centers, oil tanks, and other locations; floor systems of computer, electronic, microelectronic, communication, printing, precision instrument manufacturing, instrument manufacturing, precision machinery manufacturing, and other industrial plants.

02 Performance characteristics: Lasting anti-static effect; rapid discharge of static electricity; possesses all the excellent properties of epoxymortar flooring.

_1732777843529.webp)