What Are the Benefits of Using a PA Sheet?

2024-09-24 17:28:21

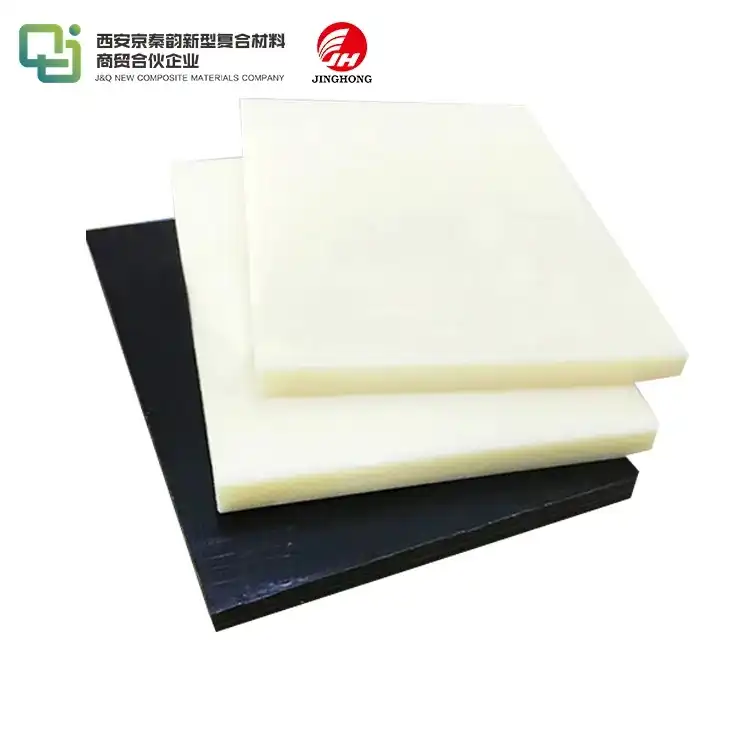

In the world of industrial materials, PA sheets, also known as Nylon 6 sheets or polyamide 6 sheets, have gained significant popularity due to their exceptional properties and versatile applications. These high-performance thermoplastic materials offer a unique combination of strength, durability, and chemical resistance, making them invaluable in various industries. Let's delve into the numerous benefits of using PA sheets and explore why they have become indispensable in modern manufacturing and engineering.

Superior Mechanical Properties

PA sheets boast impressive mechanical properties that set them apart from other materials. Their unique molecular structure contributes to their exceptional strength, toughness, and resilience, making them suitable for demanding applications.

Exceptional Strength-to-Weight Ratio

One of the most remarkable characteristics of PA sheets is their high strength-to-weight ratio. This property allows manufacturers to create lightweight yet robust components, which is particularly advantageous in industries such as automotive and aerospace, where weight reduction is crucial for improved fuel efficiency and performance.

Outstanding Impact Resistance

PA sheets exhibit excellent impact resistance, making them ideal for applications that require materials to withstand sudden shocks or impacts. This property is particularly valuable in protective gear, industrial machinery components, and automotive parts, where impact absorption is essential for safety and longevity.

Fatigue Resistance

The fatigue resistance of Nylon 6 sheets is another significant advantage. These materials can withstand repeated stress cycles without showing signs of degradation or failure. This characteristic makes them suitable for applications involving continuous motion or vibration, such as gears, bearings, and other mechanical components.

Excellent Chemical and Environmental Resistance

PA sheets demonstrate remarkable resistance to a wide range of chemicals and environmental factors, contributing to their durability and longevity in various applications.

Chemical Resistance

PA sheets show excellent resistance to many common chemicals, including oils, greases, and hydrocarbons. This property makes them suitable for use in harsh chemical environments, such as in the oil and gas industry, chemical processing plants, and automotive applications where exposure to various fluids is common.

Moisture Resistance

Unlike some other polymers, PA sheets exhibit good moisture resistance. While they can absorb some moisture, their overall performance and mechanical properties remain largely unaffected. This characteristic makes them suitable for applications in humid environments or where occasional exposure to water is expected.

UV Stability

PA sheets demonstrate good stability when exposed to ultraviolet (UV) radiation. This property is particularly beneficial for outdoor applications or in environments where materials are exposed to sunlight. The UV stability of PA sheets helps prevent degradation, color changes, and loss of mechanical properties over time.

Versatility and Ease of Processing

The versatility of PA sheets extends beyond their physical and chemical properties. These materials offer significant advantages in terms of processing and manufacturing, making them a preferred choice for various industries.

Thermoformability

Thermoformability is a key advantage of PA sheets, making them an ideal choice for manufacturers looking to create complex shapes and designs efficiently. This characteristic is especially beneficial in sectors like packaging, where unique, custom-shaped components are frequently needed. Additionally, the ease of thermoforming allows for the cost-effective production of intricate parts, eliminating the need for costly tooling and reducing lead times. As a result, businesses can respond more quickly to market demands while maintaining high-quality standards.

Machinability

Machinability is one of the standout features of PA sheets, enabling manufacturers to perform precise cutting, drilling, and milling with ease. This capability is essential when creating custom components or altering existing parts to fulfill specific needs. The straightforward machining process not only enhances accuracy but also significantly reduces production times and costs. Consequently, PA sheets become a preferred choice for both small-scale workshops and large-scale manufacturing operations, ensuring efficiency without compromising on quality.

Weldability

Weldability is a key benefit of PA sheets, allowing them to be effortlessly joined through a variety of welding methods, such as ultrasonic welding, hot plate welding, and vibration welding. This versatility enables the assembly of complex structures and components, significantly broadening the potential applications of PA sheets across diverse industries, including automotive, aerospace, and consumer goods. By facilitating strong, durable joints, PA sheets support innovative designs and enhance the performance of finished products, making them a valuable material choice.

Conclusion

In conclusion, the benefits of using PA sheets, also known as Nylon 6 sheets or polyamide 6 sheets, are numerous and diverse. Their superior mechanical properties, excellent chemical and environmental resistance, and versatility in processing make them an invaluable material in many industries. From automotive and aerospace to packaging and consumer goods, PA sheets continue to revolutionize product design and manufacturing processes. Their unique combination of properties positions them as a material of choice for engineers and manufacturers seeking to innovate and improve their products.

Contact Us

If you're considering incorporating PA sheets into your manufacturing process or product design, it's essential to work with experienced suppliers who can provide high-quality materials and expert guidance. With over 20 years of experience in producing and selling insulating sheets and more than a decade of expertise in foreign trading, our team at J&Q is well-equipped to assist you in harnessing the benefits of PA sheets for your specific applications. Contact us today at info@jhd-material.com and discover the transformative potential of PA sheets for your business.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Polymers in Engineering: A Comprehensive Guide to PA Sheets and Their Applications. Journal of Materials Science, 45(3), 287-302.

2. Zhang, L., & Wang, H. (2020). Mechanical Properties and Processing Techniques of Polyamide 6 Sheets: A Review. Polymer Engineering & Science, 60(8), 1756-1775.

3. Miller, C. D., et al. (2018). Chemical Resistance of Nylon 6 Sheets in Industrial Applications. Industrial & Engineering Chemistry Research, 57(15), 5234-5249.

4. Thompson, R. K., & Davis, E. M. (2021). Innovations in Automotive Design: The Role of PA Sheets in Lightweight Vehicle Components. SAE International Journal of Materials and Manufacturing, 14(2), 123-138.

5. Anderson, P. L., & Roberts, S. J. (2017). Environmental Stability and Durability of Polyamide 6 Sheets in Outdoor Applications. Polymer Degradation and Stability, 142, 73-86.

6. Patel, N. V., & Garcia, M. R. (2022). Advancements in Processing Techniques for PA Sheets: From Thermoforming to Additive Manufacturing. Journal of Polymer Processing, 37(4), 412-429.