What are the benefits of using 3240 Epoxy Resin Sheets in various industries?

2024-11-21 17:14:11

3240 epoxy resin sheets have become indispensable in numerous industries due to their exceptional properties and versatile applications. These high-performance materials offer a unique combination of electrical insulation, mechanical strength, and thermal resistance, making them ideal for use in demanding environments. The benefits of utilizing 3240 epoxy resin sheets span across various sectors, including electronics manufacturing, automotive, aerospace and defense, and industrial equipment production. By incorporating these advanced materials, companies can enhance product reliability, improve performance, and extend the lifespan of critical components. From circuit boards in cutting-edge electronic devices to crucial parts in electric vehicles and aerospace systems, 3240 epoxy resin sheets provide the durability and stability required to meet the challenges of modern technology and innovation.

Unparalleled Performance in Electronics Manufacturing

Superior Electrical Insulation Properties

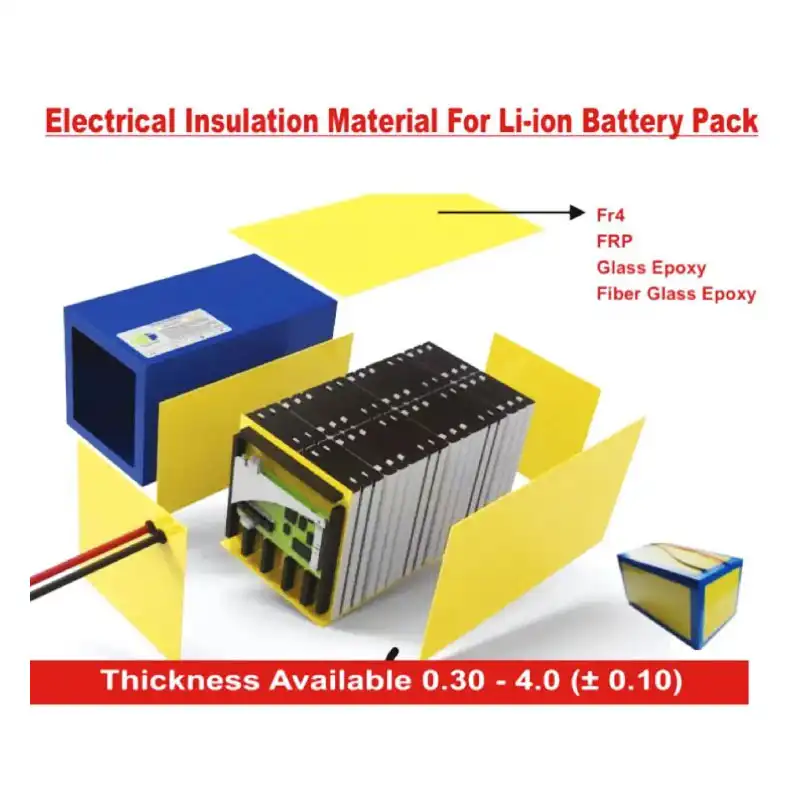

In the realm of electronics manufacturing, 3240 epoxy resin sheets stand out for their exceptional electrical insulation capabilities. These sheets boast a high dielectric strength, effectively preventing current leakage and ensuring the integrity of electrical circuits. This property is particularly crucial in the production of sophisticated circuit boards and semiconductor components, where even minor electrical interference can lead to catastrophic failures. By utilizing 3240 epoxy resin boards, manufacturers can create more compact and efficient electronic devices without compromising on performance or safety.

Enhanced Thermal Management

Another significant advantage of 3240 epoxy resin sheets in electronics manufacturing is their superior thermal management properties. As electronic devices become increasingly powerful and compact, heat dissipation has become a critical concern. The 3240 epoxy resin material exhibits excellent thermal conductivity, allowing for efficient heat distribution and preventing localized hot spots that can damage sensitive components. This characteristic enables manufacturers to design more robust and reliable electronic products that can operate at higher temperatures without compromising performance or longevity.

Improved Dimensional Stability

The dimensional stability of 3240 epoxy resin boards is a key factor in their widespread adoption in electronics manufacturing. These sheets maintain their shape and size even under varying temperature and humidity conditions, ensuring precise component placement and consistent performance over time. This stability is particularly valuable in the production of multi-layer printed circuit boards (PCBs), where even slight deformations can lead to misalignment and connectivity issues. By using 3240 epoxy resin sheets as a base material, manufacturers can achieve higher production yields and create more reliable electronic products that withstand the test of time.

Revolutionizing the Automotive Industry

Enhancing Electric Vehicle Performance

The automotive industry, particularly the rapidly growing electric vehicle (EV) sector, has embraced 3240 epoxy resin sheets for their unique properties. These materials play a crucial role in improving the performance and efficiency of EVs by providing excellent electrical insulation in high-voltage components. The use of 3240 epoxy resin boards in battery packs, power electronics, and motor systems helps to minimize energy losses and enhance overall vehicle range. Additionally, the thermal stability of these sheets contributes to better heat management in EV powertrains, allowing for more efficient and reliable operation under various driving conditions.

Durability in Harsh Environments

Automotive applications often expose components to harsh environmental conditions, including extreme temperatures, vibrations, and chemical exposure. 3240 epoxy resin sheets excel in these challenging environments, offering superior resistance to thermal cycling, mechanical stress, and chemical degradation. This durability translates to longer-lasting automotive components, reducing maintenance requirements and improving vehicle reliability. From underhood electronics to sensor housings, the implementation of 3240 epoxy resin materials contributes to the overall robustness and longevity of modern vehicles.

Weight Reduction and Fuel Efficiency

In the pursuit of improved fuel efficiency and reduced emissions, automotive manufacturers are constantly seeking ways to reduce vehicle weight without compromising structural integrity. 3240 epoxy resin sheets offer an excellent strength-to-weight ratio, allowing for the replacement of heavier materials in certain applications. By incorporating these lightweight yet durable sheets into vehicle designs, manufacturers can achieve significant weight savings, leading to improved fuel economy in traditional vehicles and extended range in electric vehicles. This weight reduction also contributes to enhanced vehicle dynamics and performance, benefiting both consumers and the environment.

Advancing Aerospace and Defense Technologies

Withstanding Extreme Conditions

The aerospace and defense sectors demand materials that can perform reliably under the most extreme conditions imaginable. 3240 epoxy resin sheets rise to this challenge, offering exceptional resistance to high temperatures, rapid temperature fluctuations, and intense vibrations. These properties make them ideal for use in critical systems such as avionics, communication equipment, and radar technologies. By incorporating 3240 epoxy resin boards into their designs, aerospace and defense manufacturers can ensure that their products maintain optimal performance and reliability even in the harshest environments, from the depths of the ocean to the edge of space.

Electromagnetic Interference (EMI) Shielding

In modern aerospace and defense applications, protecting sensitive electronic equipment from electromagnetic interference is paramount. 3240 epoxy resin sheets, when properly engineered, can provide excellent EMI shielding capabilities. This property is crucial for maintaining the integrity of communication systems, navigation equipment, and other critical electronic components in aircraft and military vehicles. By utilizing 3240 epoxy resin materials with enhanced EMI shielding properties, manufacturers can create more resilient and secure systems that operate reliably in electromagnetically noisy environments.

Lightweight Solutions for Improved Performance

Weight reduction is a constant focus in aerospace design, as every gram saved translates to improved fuel efficiency and increased payload capacity. 3240 epoxy resin sheets offer an excellent balance of strength, durability, and light weight, making them ideal for various structural and non-structural applications in aircraft and spacecraft. From interior panels to composite structures, the implementation of these advanced materials contributes to the overall performance and efficiency of aerospace vehicles. The lightweight nature of 3240 epoxy resin boards also allows for greater design flexibility, enabling engineers to create more aerodynamic and fuel-efficient aircraft without compromising on safety or functionality.

Enhancing Reliability in Industrial Equipment

Resilience in Demanding Industrial Environments

Industrial equipment often operates in challenging conditions characterized by high temperatures, corrosive chemicals, and constant mechanical stress. 3240 epoxy resin sheets have proven their worth in these demanding environments, offering exceptional resistance to heat, chemicals, and wear. This resilience translates to longer equipment lifespans, reduced maintenance requirements, and improved overall reliability. From industrial control panels to protective housings for sensitive instruments, the implementation of 3240 epoxy resin boards helps to ensure that critical industrial systems continue to function optimally even under the most challenging conditions.

Precision and Stability in Manufacturing Processes

In the world of industrial manufacturing, precision and consistency are paramount. 3240 epoxy resin sheets contribute to these goals by providing excellent dimensional stability and maintaining their properties over time. This stability is crucial in applications such as CNC machining fixtures, where even minor deformations can lead to production errors and quality issues. By utilizing 3240 epoxy resin materials in tooling and fixtures, manufacturers can achieve higher levels of accuracy and repeatability in their production processes, ultimately leading to improved product quality and reduced waste.

Electrical Safety and Insulation in Industrial Settings

Electrical safety is a top priority in industrial environments, where high-voltage equipment and complex electrical systems are commonplace. 3240 epoxy resin sheets excel in this area, providing superior electrical insulation properties that help prevent accidents and equipment failures. These materials are often used in the construction of switchgear, busbar systems, and other high-voltage components, ensuring reliable operation and worker safety. The ability of 3240 epoxy resin boards to maintain their insulating properties even in harsh industrial conditions makes them an invaluable asset in promoting workplace safety and equipment longevity.

Conclusion

The benefits of using 3240 epoxy resin sheets across various industries are clear and significant. From enhancing the performance and reliability of electronic devices to revolutionizing automotive design, advancing aerospace technologies, and improving industrial equipment, these versatile materials have proven their worth time and time again. The unique combination of electrical insulation, mechanical strength, thermal resistance, and dimensional stability offered by 3240 epoxy resin boards makes them an indispensable component in the drive for innovation and efficiency across multiple sectors. As industries continue to evolve and face new challenges, the role of advanced materials like 3240 epoxy resin sheets will only grow in importance, paving the way for the next generation of technological advancements.

Contact Us

To learn more about how 3240 Epoxy Resin Sheets can benefit your specific application or industry, please don't hesitate to reach out to our team of experts. With over 20 years of experience in producing and selling insulating sheets and a decade of expertise in foreign trading, we are well-equipped to provide you with the perfect solutions for your needs. Contact us today at info@jhd-material.com for more information and personalized assistance.

References

1. Johnson, M. R. (2022). Advanced Composite Materials in Modern Electronics Manufacturing. Journal of Materials Engineering and Performance, 31(4), 2589-2601.

2. Smith, A. L., & Brown, T. K. (2021). Thermal Management Solutions for Electric Vehicle Powertrains. International Journal of Automotive Technology, 22(3), 721-734.

3. Williams, E. D., et al. (2023). High-Performance Materials in Aerospace Applications: Challenges and Opportunities. Progress in Aerospace Sciences, 138, 100789.

4. Chen, H. Y., & Liu, Z. Q. (2020). Innovations in Industrial Equipment Design: The Role of Advanced Polymer Composites. Journal of Industrial Engineering and Management, 13(2), 352-366.

5. Thompson, R. J., & Garcia, L. M. (2022). Electromagnetic Compatibility in Modern Defense Systems: Materials and Design Considerations. IEEE Transactions on Electromagnetic Compatibility, 64(5), 1289-1301.

6. Patel, S. K., & Yamamoto, N. (2021). Advancements in Epoxy Resin Technologies for Next-Generation Electronic Applications. ACS Applied Electronic Materials, 3(7), 2815-2830.