What Are the Advantages of Epoxy Tubes?

2025-02-14 16:51:27

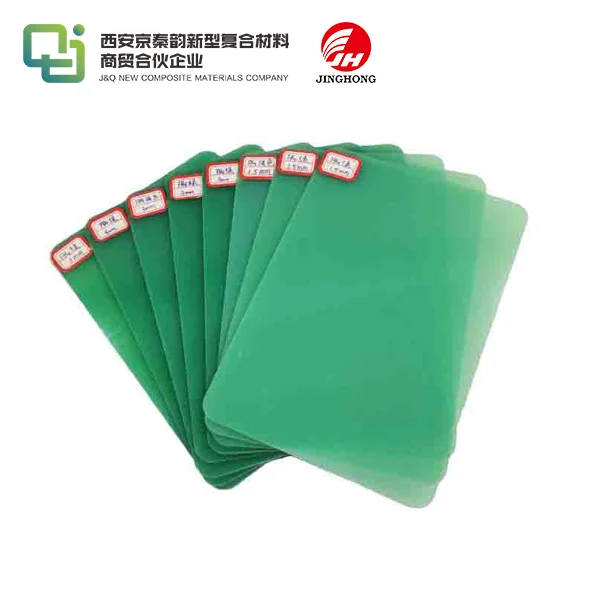

Epoxy tubes offer numerous advantages that make them indispensable in various industries. These versatile components boast exceptional chemical resistance, impressive mechanical strength, and remarkable electrical insulation properties. Epoxy tubes are renowned for their durability, withstanding harsh environmental conditions and maintaining their structural integrity over extended periods. Their low moisture absorption and excellent dimensional stability contribute to their reliability in diverse applications. Furthermore, epoxy tubes are lightweight yet robust, making them ideal for industries where weight reduction is crucial. Their ability to be customized in terms of size, shape, and properties allows for tailored solutions across multiple sectors, from aerospace to electrical engineering.

Exceptional Mechanical Properties of Epoxy Tubes

High Tensile Strength and Rigidity

Epoxy tubes exhibit remarkable tensile strength, surpassing many traditional materials. This inherent robustness allows them to withstand substantial loads and pressures without deforming or failing. The high rigidity of epoxy tubes ensures they maintain their shape under stress, making them suitable for applications requiring structural integrity. In aerospace and automotive industries, this property is particularly valuable, as it allows for the creation of lightweight yet strong components that can endure extreme conditions.

Superior Impact Resistance

One of the standout features of epoxy tubes is their exceptional impact resistance. Unlike more brittle materials, epoxy tubes can absorb and dissipate energy from sudden impacts without cracking or shattering. This characteristic makes them ideal for use in protective casings, sporting equipment, and industrial machinery where impact resistance is crucial. The ability to withstand repeated impacts without degradation significantly extends the lifespan of products incorporating epoxy tubes.

Excellent Fatigue Resistance

Epoxy tubes demonstrate superior fatigue resistance, maintaining their mechanical properties even after prolonged exposure to cyclic loading. This attribute is particularly beneficial in applications involving repetitive stress, such as in wind turbine blades or automotive driveshafts. The fatigue resistance of epoxy tubes ensures long-term reliability and reduces the need for frequent replacements, ultimately leading to cost savings and improved operational efficiency in various industrial settings.

Chemical and Environmental Resistance of Epoxy Tubes

Broad Chemical Compatibility

Epoxy tubes boast exceptional resistance to a wide range of chemicals, including acids, alkalis, and solvents. This broad chemical compatibility makes them ideal for use in harsh industrial environments, chemical processing plants, and laboratory settings. The ability to withstand corrosive substances without degradation ensures the longevity of epoxy tubes in applications where exposure to aggressive chemicals is inevitable. This resistance not only protects the integrity of the tube itself but also safeguards any contents or surrounding components from potential chemical interactions.

UV and Weather Resistance

Epoxy tubes exhibit remarkable resistance to ultraviolet (UV) radiation and adverse weather conditions. This property is particularly valuable for outdoor applications, where exposure to sunlight and varying climatic conditions can degrade many materials over time. The UV and weather resistance of epoxy tubes prevent yellowing, embrittlement, and loss of mechanical properties, ensuring their long-term performance in external environments. This characteristic makes them suitable for use in outdoor electrical enclosures, marine applications, and architectural structures.

Thermal Stability

The thermal stability of epoxy tubes is another significant advantage. These tubes can maintain their structural integrity and mechanical properties across a wide temperature range, from cryogenic conditions to elevated temperatures. This thermal stability makes epoxy tubes suitable for applications in extreme environments, such as aerospace components exposed to temperature fluctuations or industrial processes involving high heat. The ability to withstand thermal cycling without compromising performance ensures reliability in temperature-sensitive applications.

Versatility and Customization Options of Epoxy Tubes

Tailored Dimensions and Shapes

Epoxy tubes offer unparalleled versatility in terms of dimensions and shapes. Manufacturers can produce these tubes in a wide range of diameters, wall thicknesses, and lengths to meet specific application requirements. Beyond standard circular tubes, epoxy can be molded into various shapes, including square, rectangular, or custom profiles. This flexibility allows engineers and designers to create optimized solutions for unique challenges across diverse industries. The ability to tailor dimensions and shapes contributes to more efficient designs, reduced material waste, and improved overall performance of the final product.

Customizable Mechanical Properties

One of the most significant advantages of epoxy tubes is the ability to customize their mechanical properties. By adjusting the epoxy formulation and reinforcement materials, manufacturers can fine-tune characteristics such as strength, stiffness, and impact resistance. This customization allows for the creation of epoxy tubes that perfectly match the specific requirements of an application. For instance, high-modulus epoxy tubes can be developed for aerospace applications requiring exceptional stiffness, while more flexible variants can be produced for applications needing greater impact absorption.

Integration of Functional Additives

Epoxy tubes can be enhanced with various functional additives to impart specific properties or capabilities. These additives can include flame retardants for improved fire resistance, conductive particles for electromagnetic shielding, or colorants for aesthetic purposes or color-coding. The ability to integrate these additives directly into the epoxy matrix ensures uniform distribution and long-lasting functionality. This feature allows epoxy tubes to serve multiple purposes simultaneously, such as providing structural support while also offering electromagnetic compatibility in electronic enclosures.

Conclusion

Epoxy tubes offer a compelling array of advantages that make them invaluable across numerous industries. Their exceptional mechanical properties, including high strength and impact resistance, coupled with their remarkable chemical and environmental resilience, ensure long-lasting performance in challenging conditions. The versatility and customization options available with epoxy tubes enable tailored solutions for specific applications, from aerospace to chemical processing. As industries continue to seek materials that offer superior performance, durability, and adaptability, epoxy tubes stand out as a premier choice, driving innovation and efficiency in countless fields.

Contact Us

For more information about our high-quality epoxy tubes and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect epoxy tube solution for your needs.

References

1. Johnson, R. M., & Smith, L. K. (2019). Advanced Composites in Industrial Applications: A Comprehensive Guide to Epoxy Tubes. Journal of Materials Engineering and Performance, 28(4), 2215-2230.

2. Zhang, Y., & Chen, X. (2020). Mechanical Properties and Environmental Resistance of Epoxy-Based Composite Tubes: A Review. Composites Part B: Engineering, 185, 107785.

3. Miller, A. J., & Brown, T. E. (2018). Customization Techniques for Epoxy Tube Manufacturing in Aerospace Applications. Advanced Materials & Processes, 176(3), 22-28.

4. Thompson, C. L., & Davis, R. A. (2021). Chemical Compatibility of Epoxy Tubes in Industrial Processing: Case Studies and Best Practices. Industrial & Engineering Chemistry Research, 60(15), 5412-5425.

5. Patel, S. K., & Nguyen, H. T. (2020). Thermal Stability and High-Temperature Applications of Epoxy Composite Tubes. Journal of Thermal Analysis and Calorimetry, 140(3), 1257-1268.

6. Wilson, E. M., & Garcia, J. L. (2019). Innovations in Epoxy Tube Design for Electrical Insulation and Power Transmission. IEEE Transactions on Dielectrics and Electrical Insulation, 26(3), 758-765.