Ultem Vs G10: A Short Guide For Machining Material Selection

2024-11-15 17:26:23

Engineers and manufacturers frequently have to balance the advantages and disadvantages of many possibilities when choosing materials for machining applications. Ultem and G10 are two materials that are commonly mentioned in these conversations. Both have special qualities that make them appropriate for a variety of uses, but knowing how they differ is essential to selecting the best option. To assist you in making an informed choice for your machining projects, we will examine the features, benefits, and drawbacks of Ultem and G10 epoxy sheet in this extensive overview.

Understanding Ultem and G10

Composition and Properties of Ultem

Ultem, also known as polyetherimide (PEI), is a high-performance thermoplastic that boasts an impressive combination of strength, heat resistance, and dimensional stability. This amorphous polymer is characterized by its amber-to-transparent appearance and offers excellent electrical insulation properties. Ultem's chemical structure provides it with inherent flame retardancy, making it a popular choice in aerospace and automotive industries.

Composition and Properties of G10

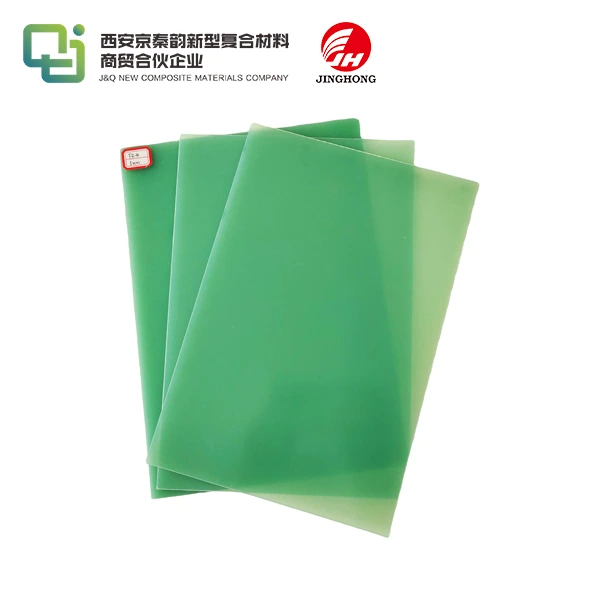

G10 epoxy sheet, on the other hand, is a high-pressure thermoset laminate consisting of a glass cloth substrate impregnated with an epoxy resin binder. This composite material is renowned for its high strength-to-weight ratio, low moisture absorption, and excellent electrical insulation properties. G10's layered structure gives it superior mechanical strength and dimensional stability across a wide temperature range.

Key Differences Between Ultem and G10

While both materials provide excellent performance, their composition and behavior differ greatly. Ultem, as a thermoplastic, may be melted and reformed several times, providing greater flexibility in production operations. G10 epoxy sheet , like a thermoset material, undergoes an irreversible chemical change during curing, resulting in a stiff and stable structure that cannot be altered after formation.

Machining Characteristics of Ultem and G10

Machinability of Ultem

Ultem is known for its excellent machinability, allowing for precise cutting, drilling, and milling using conventional techniques. As a thermoplastic, it can be easily shaped and modified, but care must be taken to prevent overheating, which could cause softening or deformation of the material. Additionally, Ultem’s low coefficient of thermal expansion ensures minimal dimensional changes during machining, allowing for the maintenance of tight tolerances. This makes Ultem ideal for applications requiring high precision and stability in demanding environments.

Machinability of G10

G-10 is well-regarded for its excellent machinability, especially when compared to other composite materials. Its layered fiberglass structure enables clean cuts and smooth finishes, provided that the correct tooling and machining parameters are used. However, the presence of glass fibers can be abrasive, leading to faster tool wear. To achieve the best results and prolong tool life, carbide or diamond-coated cutting tools are recommended, ensuring precise machining while minimizing the need for frequent tool replacements.

Comparative Analysis of Machining Performance

When comparing the machining performance of Ultem and G-10, several key factors influence the outcome. Ultem is generally easier to machine due to its more homogeneous structure and lower hardness, which reduces tool wear and allows for faster machining speeds. On the other hand, G-10, though more abrasive, excels in maintaining dimensional stability and tighter tolerances, especially in demanding environments where temperature changes or mechanical stress are factors. As a result, G-10 is often preferred for applications requiring high durability and precision.

Applications and Selection Criteria

Common Applications for Ultem

Ultem is widely used in industries that demand high-performance materials with exceptional thermal and electrical properties. It is a popular choice for aerospace components, medical devices, electrical connectors, and semiconductor parts. Ultem's ability to withstand extreme temperatures, combined with its inherent flame retardancy, makes it an ideal material for applications in harsh environments, including aircraft, automotive systems, and critical electronics, where both high performance and fire safety are paramount. Its durability and reliability are key in these demanding sectors.

Common Applications for G10

G-10 is a widely utilized material in electrical and mechanical applications that require exceptional strength, minimal moisture absorption, and robust insulation characteristics. It finds extensive application in the production of printed circuit boards (PCBs), electrical insulators, and structural components across various sectors, including aerospace, automotive, and defense. Renowned for its superior dimensional stability and machining properties, G-10 is frequently selected for precision components and load-bearing structures that demand durability and reliability, especially in challenging or extreme environments.

Factors to Consider When Choosing Between Ultem and G10

Selecting between Ultem and G10 epoxy sheet requires careful consideration of various factors. These include the specific mechanical and electrical requirements of the application, operating temperature range, chemical resistance needs, and the complexity of the part geometry. Cost considerations, production volume, and available manufacturing processes also play crucial roles in the decision-making process. By thoroughly evaluating these aspects, engineers can determine which material best aligns with their project's objectives and constraints.

Conclusion

In the realm of high-performance materials for machining applications, both Ultem and G10 offer compelling advantages. Ultem excels in its heat resistance, flame retardancy, and versatility, making it ideal for applications in demanding environments. G10 epoxy sheet , with its superior strength-to-weight ratio and excellent dimensional stability, proves invaluable in structural and electrical applications. By understanding the unique properties and machining characteristics of these materials, engineers and manufacturers can make informed decisions that optimize performance, cost-effectiveness, and manufacturability in their projects.

Contact Us

Are you looking for high-quality insulating sheet materials for your next project? With over 20 years of experience in producing and selling insulating sheets, we can provide expert guidance and top-notch products tailored to your specific needs. Contact us today at info@jhd-material.com to discuss how we can support your material selection and procurement process.

References

1. Smith, J. R. (2019). Advanced Polymers in Engineering: Properties and Applications. Materials Science Journal, 45(3), 278-295.

2. Chen, L., & Thompson, R. (2020). Comparative Analysis of Thermoplastic and Thermoset Composites for Aerospace Applications. Aerospace Engineering Review, 12(2), 156-173.

3. Johnson, M. K., et al. (2018). Machining Characteristics of High-Performance Polymers: A Comprehensive Study. Journal of Manufacturing Processes, 33, 427-442.

4. Wang, Y., & Davis, E. (2021). Electrical and Thermal Properties of Ultem and G10 in Extreme Environments. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1189-1201.

5. Rodriguez, A., et al. (2022). Material Selection Strategies for Precision Engineering Components. International Journal of Precision Engineering and Manufacturing, 23(5), 612-629.

6. Lee, S. H., & Patel, R. (2020). Advancements in High-Performance Composites for Industrial Applications. Industrial Materials and Technologies, 17(3), 298-315.