Bakelite: The First Synthetic Plastic and Its Applications

2024-12-04 17:13:53

In the realm of materials science, few inventions have had as profound an impact as Bakelite, the world's first fully synthetic plastic. This revolutionary material, developed in the early 20th century, paved the way for the modern plastics industry and found applications in countless fields. In this comprehensive exploration, we'll delve into the history, properties, and diverse applications of Bakelite, shedding light on its enduring legacy and continued relevance in today's world.

|

|

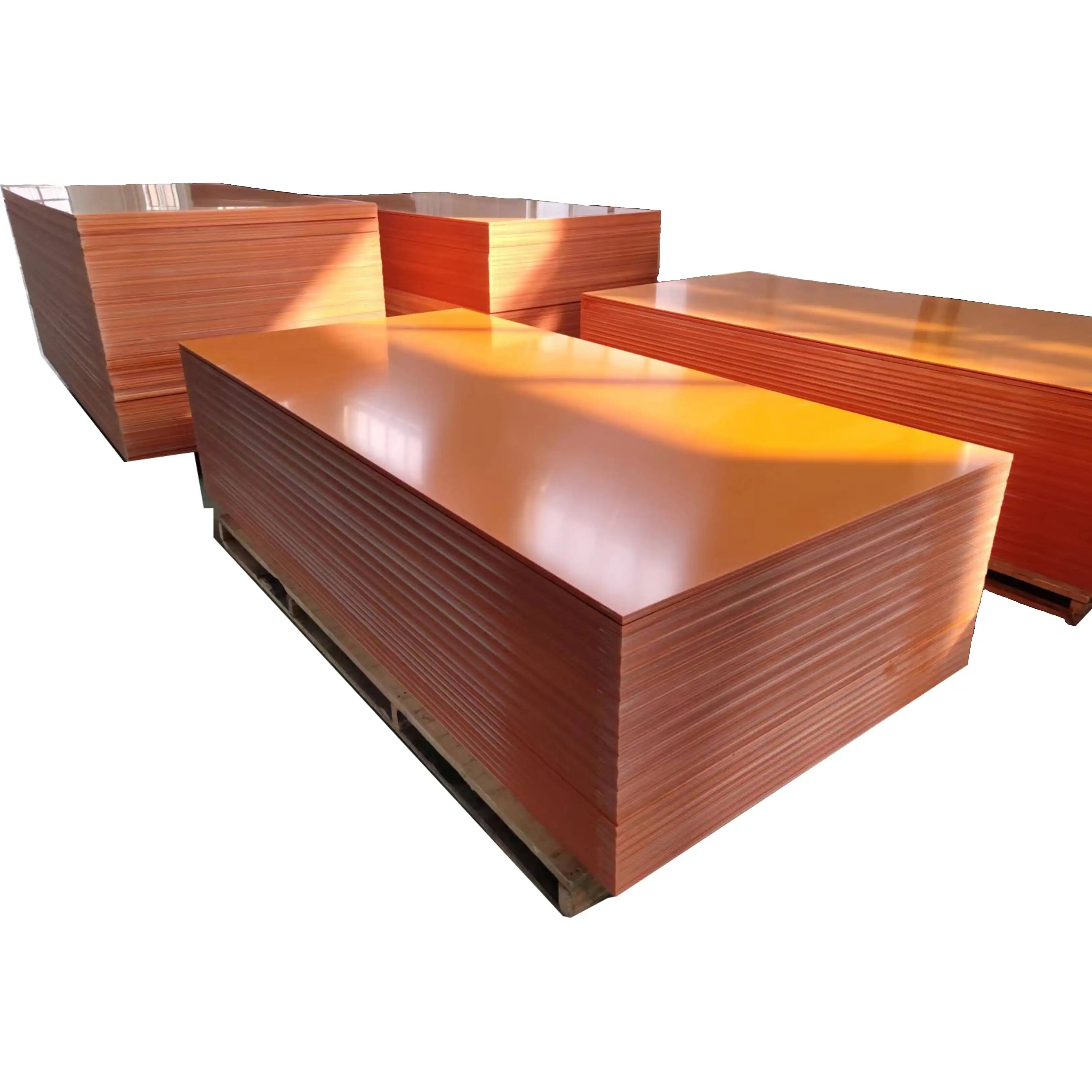

Basic Information: Brand: JingHong Materials: Phenolic Resin Nature Color: Black and Orange Thickness: 2mm --- 100mm Regular Size: 1040mm*2080mm Custom Size: 1220mm*2440mm Packaging: Regular packing, Protect by Pallet |

| Contact Us | |

The Genesis of Bakelite: A Pioneering Discovery

Leo Baekeland's Eureka Moment

The story of Bakelite begins with Belgian-American chemist Leo Baekeland. In 1907, Baekeland's relentless experimentation with phenol and formaldehyde culminated in the creation of a unique substance. This material, which he later named Bakelite, possessed remarkable properties that set it apart from any existing materials of the time.

Chemical Composition and Synthesis

Bakelite is a thermosetting phenol formaldehyde resin, formed through a complex process of polymerization. The reaction between phenol and formaldehyde, under specific conditions of heat and pressure, results in a cross-linked polymer structure. This unique molecular arrangement gives Bakelite its characteristic properties, including heat resistance, electrical insulation, and durability.

Patent and Commercialization

Recognizing the potential of his discovery, Baekeland swiftly filed for a patent. In 1909, he was granted U.S. Patent No. 942,699, marking the official birth of Bakelite. The commercialization of this new material soon followed, with the establishment of the General Bakelite Company in 1910. This move set the stage for the rapid proliferation of Bakelite across various industries.

Distinctive Properties of Bakelite: A Material Like No Other

Heat Resistance and Electrical Insulation

One of Bakelite's most prized attributes is its exceptional heat resistance. Unlike many other materials of its time, Bakelite maintains its structural integrity even at high temperatures. This property, coupled with its excellent electrical insulation capabilities, made it an ideal choice for numerous electrical and mechanical applications. From switchboards to radio casings, Bakelite quickly became indispensable in the burgeoning electronics industry.

Chemical Resistance and Durability

Bakelite's resistance to chemical degradation is another feather in its cap. This durability extends its lifespan and makes it suitable for use in harsh environments. The material's ability to withstand acids, bases, and various solvents contributed to its adoption in laboratory equipment and industrial machinery. Moreover, Bakelite's resistance to wear and tear ensured its longevity in consumer products, from kitchenware to automotive parts.

Moldability and Versatility

Perhaps one of Bakelite's most revolutionary aspects was its moldability. The material could be shaped into virtually any form while in its initial state, then set permanently through heat and pressure. This characteristic opened up a world of possibilities in manufacturing and design. Bakelite could be molded into intricate shapes, allowing for mass production of complex parts with consistent quality. Its versatility in color and finish further expanded its appeal across various industries and consumer markets.

The Myriad Applications of Bakelite: From Industry to Art

Electrical and Electronics

In the realm of electrical applications, Bakelite reigned supreme for decades. Its excellent insulating properties made it the material of choice for a wide array of components. Electrical sockets, switch plates, and radio cabinets were commonly crafted from Bakelite. The material's heat resistance also made it ideal for components in high-temperature environments, such as light fixtures and automotive distributor caps. Even today, certain specialized electrical applications still rely on Bakelite's unique properties.

Industrial and Mechanical Uses

Bakelite's impact on industrial manufacturing cannot be overstated. Its strength, heat resistance, and moldability made it an excellent material for gears, bearings, and other mechanical components. In the automotive industry, Bakelite found its way into various parts, from distributor caps to steering wheels. The material's chemical resistance also made it valuable in laboratory equipment, where it was used for everything from beaker handles to instrument casings. In the aerospace industry, Bakelite components played a crucial role in early aircraft design, contributing to advancements in aviation technology.

Consumer Goods and Artistic Expression

Beyond its industrial applications, Bakelite left an indelible mark on consumer goods and popular culture. In the realm of kitchenware, Bakelite handles adorned pots, pans, and utensils, prized for their heat resistance and durability. The material's versatility in color and finish made it a favorite among designers, leading to iconic pieces of Art Deco jewelry and decorative objects. Bakelite radios, with their sleek designs and vibrant colors, became symbols of modernity in mid-20th century homes. Today, vintage Bakelite items are highly sought after by collectors, appreciated not only for their historical significance but also for their aesthetic appeal.

Conclusion

Bakelite's invention marked a pivotal moment in materials science, ushering in the age of synthetic plastics. Its unique properties revolutionized numerous industries and paved the way for countless innovations. While newer materials have superseded Bakelite in many applications, its legacy endures. The principles behind its development continue to inspire material scientists and engineers in their quest for novel substances. As we look to the future of materials science, the story of Bakelite serves as a testament to the power of scientific curiosity and innovation.

Contact Us

Are you interested in learning more about innovative materials and their applications in insulation? At J&Q, we specialize in cutting-edge insulating sheets that build upon the legacy of materials like Bakelite. For more information about our products and services, please contact us at info@jhd-material.com. Let's explore how our expertise can benefit your projects!

References

1. Kaufman, M. (1988). The First Century of Plastics: Celluloid and its Sequel. The Plastics and Rubber Institute.

2. Bijker, W. E. (1997). Of Bicycles, Bakelites, and Bulbs: Toward a Theory of Sociotechnical Change. MIT Press.

3. Fenichell, S. (1996). Plastic: The Making of a Synthetic Century. HarperBusiness.

4. Meikle, J. L. (1995). American Plastic: A Cultural History. Rutgers University Press.

5. Mossman, S. T. I. (2008). Early Plastics: Perspectives, 1850–1950. Leicester University Press.

6. Friedel, R. (1983). Pioneer Plastic: The Making and Selling of Celluloid. University of Wisconsin Press.

_1747991245292.webp)