PCB Insulation Guide

2024-01-04

When current flows through a PCB or printed circuit board, it generates heat. Without proper insulation, this heat can cause serious issues for the PCB.

Why do PCBs need insulation?

To understand PCB insulation, it is crucial to understand what a PCB is.

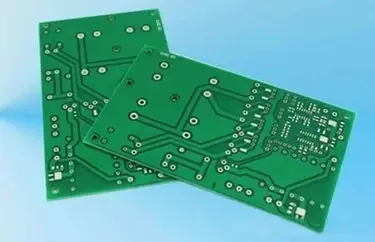

A PCB, or printed circuit board, is a green (or other colored) square with copper traces on it. They can be found in almost all electronic devices! Printed circuit boards make electronic devices work properly, making them an essential but often invisible part of daily life.

Electricity is highly functional for PCBs. PCBs contain printed copper wires, so they naturally conduct electricity. However, if electrical components are not encapsulated in non-conductive housings or become too hot, danger can result. PCBs must be insulated to prevent copper elements from corroding and reduce accidental contact with conductive materials. Proper insulation can help prevent PCB overheating or exploding.

There are multiple ways to isolate PCBs. There are several common insulation materials, but the exact type of insulation typically depends on the application for which the PCB is designed.

PCB insulation materials

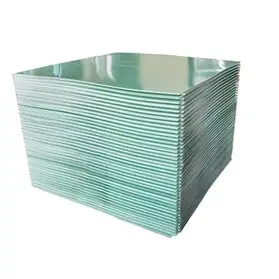

Common PCB insulation materials typically take the form of non-conductive substrates that can be fused together in multiple layers to allow current to flow correctly throughout the circuit board. Simpler PCBs can be single-sided or single-layered. Complex PCBs (such as those used for high-speed digital communication) may contain over twenty layers.

A PCB insulation calculator can help you determine creepage distance and electrical clearance, which will be deciding factors for the exact type and amount of insulation material. Creepage distance is the shortest distance between conductive parts, while clearance refers to elements separated by air rather than substrate. Understanding creepage distance and electrical clearance is critical for calculating PCB insulation.

PCB manufacturing companies can choose from multiple different materials for insulation, ranging from inexpensive plastics like FR-2 to sturdy and durable metals like aluminum. The material used for PCB insulation typically depends on the intended use. For example, PCBs in inexpensive electronic toys will not require the same type of insulation as those in artificial satellites.

To better understand PCB insulation materials and forms of insulation, let's explore the five most common forms of PCB insulation materials.

FR-2

FR-2 is a low-grade flame-retardant laminate option. It is a composite material made of paper and phenolic resin, making it both lightweight and durable. Single-sided circuit boards typically use this material. FR-2 is halogen-free, non-hydrophobic, and easy to punch or mill. FR-2 is one of the cheapest options for PCB insulation and is a common choice for companies producing disposable consumer electronics.

FR-4

FR-4 is a high-grade flame-retardant laminate option. It is a composite material made of glass fiber woven fabric and is typically used in the manufacture of double-sided and multi-layer PCBs. FR-4 can withstand higher temperatures and physical pressure compared to FR-2. It is also an economical material, making it a popular choice for high-end consumer electronics manufacturers. FR-4's mechanical processing speed is not fast and requires milling, punching, or machining with tungsten carbide tools.

RF

RF substrates are designed to allow PCBs to operate in applications that involve high-power RF and microwaves. RF substrates are most commonly used in military electronics, avionics, and aerospace electronics installations. Note, however, that some consumer electronics products contain this type of substrate. The plastics that make up typical RF substrates do not produce a lot of insulation, but perform well when tasked with generating large currents. RF and microwave PCBs usually only have one or two layers.

Flexible

Although most printed circuit boards are flat and rigid, there are still some innovative PCBs that can bend in almost any direction without breaking. Flexible circuits require a similar but unique form of insulation. Flexible circuits are typically protected using PCB insulation sprays, and plastic film is also a popular choice. Flexible circuits require thin yet robust PCB insulation coatings so that they can move freely and fit into narrow spaces.

Metal

Choosing metal as an insulator may seem odd. Metals are typically conductive, and accidental conductivity can cause PCB faults, fires or melting. However, in certain situations, PCBs with metal substrates may be advantageous. Metal is an excellent conductor of heat and can withstand large currents without fracturing or burning. PCBs installed in power-consuming devices may require metal substrates to function effectively.

Industry impact

To prevent PCBs from overheating, catching fire, or exploding, they must be adequately insulated. The type of insulation material corresponds to the type of use provided by the PCB.

General electronic PCBs are suitable for using simpler, more cost-effective FR-2 or FR-4 substrates. RF substrates are better suited for applications involving high-power RF.

Flexible substrates like plastics are ideal for meeting the insulation needs of flexible circuit boards. Metals can keep power electronics cool while maintaining excellent thermal conductivity.

拷贝.webp)