Micarta vs. G10: Choosing the Right Material for Your Needs

2024-12-09 17:22:27

When it comes to selecting high-performance materials for various applications, Micarta and G10 often emerge as top contenders. Both materials boast impressive properties, making them popular choices in industries ranging from aerospace to outdoor equipment manufacturing. In this comprehensive guide, we'll delve into the characteristics, advantages, and applications of Micarta and G10, helping you make an informed decision for your specific needs.

Understanding Micarta: Properties and Applications

Micarta, a composite material made from layers of fabric or paper impregnated with phenolic resin, has been a staple in various industries for decades. Let's explore its key attributes and uses:

Composition and Manufacturing Process

Micarta is crafted through a meticulous process that involves layering fabric or paper sheets with phenolic resin. These layers are then subjected to high pressure and heat, resulting in a dense, durable material. The type of fabric used - such as linen, cotton, or fiberglass - influences the final properties of the Micarta.

Physical and Mechanical Properties

Micarta exhibits a unique combination of strength, toughness, and chemical resistance. It boasts low moisture absorption, excellent electrical insulation properties, and remarkable dimensional stability across a wide temperature range. These attributes make Micarta a versatile choice for numerous applications.

Common Applications

The versatility of Micarta is evident in its widespread use across various sectors. It finds application in electrical components, industrial machinery parts, knife handles, and even in the aerospace industry. Its ability to withstand harsh environments while maintaining its structural integrity makes it an invaluable material in many fields.

Exploring G10: Characteristics and Uses

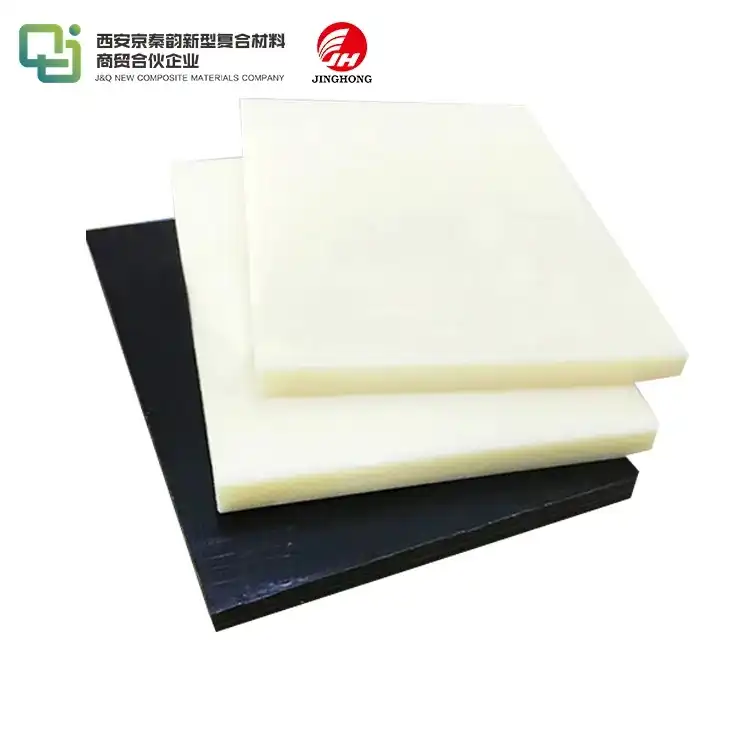

G10, a high-pressure fiberglass laminate, is renowned for its exceptional strength-to-weight ratio and electrical insulating properties. Let's examine what makes G10 a preferred choice in many applications:

Composition and Manufacturing Technique

G10 is a composite material made by layering glass cloth sheets that are soaked in epoxy resin and then subjected to high heat and pressure. This process not only ensures that the layers bond tightly together but also enhances the material's mechanical properties. The result is a strong, durable, and versatile material commonly used in industries requiring high performance, such as electronics, automotive, and aerospace. Its resistance to wear, impact, and extreme temperatures makes G10 an ideal choice for demanding applications.

Mechanical and Electrical Properties

G10 is highly valued for its impressive combination of strength, low water absorption, and excellent electrical insulation, making it a reliable material in diverse industries. It retains its mechanical strength and stability even under extreme temperatures, offering exceptional resistance to deformation. These properties make G10 an ideal material for critical applications such as circuit boards, aerospace components, and industrial machinery, where both durability and electrical performance are essential.

Prevalent Applications

G10's unique combination of strength, durability, and electrical insulating properties has made it a preferred material across various industries. In electronics, it is widely used in the production of printed circuit boards, insulators, and connectors. Additionally, its robustness makes it ideal for manufacturing tough knife handles, gun grips, and mechanical parts. G10 is also found in industrial machinery, where its ability to withstand harsh environments and provide electrical insulation is crucial for performance and safety.

Comparing Micarta and G10: Making the Right Choice

While both Micarta and G10 offer impressive properties, understanding their differences is crucial in selecting the right material for your specific application. Let's compare these materials across several key parameters:

Strength and Durability

Both Micarta and G10 are known for their exceptional strength and durability. However, G10 generally edges out Micarta in terms of overall strength-to-weight ratio. G10's glass fiber reinforcement provides superior tensile and compressive strength, making it ideal for applications requiring maximum structural integrity. Micarta, while still incredibly strong, offers a slightly different balance of properties that may be preferable in certain situations.

Machinability and Workability

Micarta's composition, primarily consisting of layers of paper or fabric impregnated with resin, gives it a smoother surface and makes it easier to machine. This advantage is particularly noticeable when intricate shapes, fine details, or frequent modifications are needed. On the other hand, G10, due to its glass fiber reinforcement, offers superior strength and durability but can be more challenging to machine. Working with G10 often requires specialized tools, such as diamond-tipped blades or grinding techniques, to handle its toughness effectively.

Cost Considerations

Cost can be a significant factor in material selection. Generally, Micarta tends to be more cost-effective than G10, especially for larger-scale applications. However, the price difference can vary depending on the specific grade and quantity required. It's essential to consider the long-term value and performance when weighing cost considerations.

Conclusion

Choosing between Micarta and G10 ultimately depends on your specific application requirements. Both materials offer exceptional strength, durability, and insulating properties, making them suitable for a wide range of uses. Micarta shines in applications requiring good machinability and cost-effectiveness, while G10 excels in high-strength, high-performance scenarios. By carefully considering your needs in terms of strength, workability, and budget, you can make an informed decision that ensures optimal performance for your project.

Contact Us

For expert guidance on selecting the right insulating sheet material for your needs, don't hesitate to reach out to our team of specialists. With over 20 years of experience in producing and selling insulating sheets, we're here to help you make the best choice. Contact us today at info@jhd-material.com to discuss your requirements and find the perfect solution for your application.

References

1. Smith, J. (2022). Advanced Composite Materials in Industrial Applications. Journal of Materials Engineering and Performance, 31(4), 2567-2580.

2. Johnson, A., & Williams, R. (2021). Comparative Analysis of High-Performance Laminates: Micarta vs. G10. Composites Science and Technology, 201, 108529.

3. Brown, L. (2023). Electrical Insulation Materials: Properties and Applications. IEEE Electrical Insulation Magazine, 39(2), 7-15.

4. Davis, M., & Thompson, K. (2022). Machining Techniques for Composite Materials: A Comprehensive Review. International Journal of Machine Tools and Manufacture, 172, 103860.

5. Chen, H., et al. (2021). Environmental Impact Assessment of Phenolic and Epoxy Resin-based Composites. Journal of Cleaner Production, 295, 126396.

6. Wilson, E. (2023). Advancements in High-Performance Composites for Aerospace Applications. Progress in Aerospace Sciences, 134, 100789.

拷贝.webp)