Laminate Molding Process

2021-06-23

The lamination process is an important process in lamination molding. The lamination process is to press the impregnated tape to form a slab with the required thickness, place it in two polished metal templates, place it on a hot press, heat and press between the two templates, and then heat and press to cure it. Cool down and demold.

1. Laminating Equipment

The main equipment is a heat press unit. Auxiliary equipment includes loading and unloading machines, template turning machines, template cleaning machines, and pattern cleaning machines (stacking machines). From the production mix, it is divided into a single machine for hot pressing and cooling and two hot pressing and cooling machines.

At present, there are two kinds of hot presses used in China and abroad: open-type hot press and closed vacuum hot press. Compared with the open heat press, the vacuum heat press has two outstanding advantages: 1. The unit pressure of the molding is lower by 1/2-1/3, that is, the flow of glue is reduced, the movement of the warp and weft of the cloth is small, and the internal pressure of the laminate is reduced. Stress, and finally achieve the purpose of reducing the degree of warpage; 2. It can avoid bubbles in the board and corners, and the quality of the product is higher; the application of vacuum hot pressing in composite material molding is more and more extensive.

The performance and control level of the hot press directly affect the quality of the product, and at the same time have a direct relationship with the molding process. The hot press mainly controls the temperature field and pressure of the heating plate.

1. Heating Plate

The structure of the heating plate and the heating medium used directly affect the uniformity of the temperature field of the heating plate, the uniformity of the plate surface temperature, the uniformity of the melting of the adhesive tape, and the discharge of the gas generated after gelation and the air between the tape layers. Therefore, the heating speed of the heating plate should be fast and uniform, and the temperature difference of the plate surface should be less than 3°C.

There are two types of heating plate channels: single-in and single-out and double-in and double-out. The latter is complicated to manufacture, piping is also complicated, and the cost is high, so it is rarely used. The former adopts steam heating, and the plate surface temperature difference is relatively large (about 5°C); when hot water or heat transfer oil is used, the plate surface temperature difference is less than 3°C; the effect of using heat transfer oil is better because the pressure of heat transfer oil is low (less than 0.5MPa), high temperature (up to about 300°C).

For the temperature control of the whole machine, there are generally 12-20 openings in the hot press, so that the heating plate presents a temperature gradient from bottom to top. Steam heating is more single-point total control, and the gradient is about 5°C. Hot water or heat transfer oil is generally controlled by zones (generally divided into 2-3 zones), and the temperature gradient is only controlled with an error of less than 3°C. This is conducive to the same pressure, the upper, middle and lower solidification speeds are the same, which is beneficial to improve product quality.

2. Pressure

At present, most of the hot pressing uses hydraulic presses, which can meet the unit pressure required for product molding, up to 12.5MPa, and the pressure is stable less than ±500KPa, which can be set according to process requirements. The tonnage of the multi-layer press is generally larger, usually 2000-3000t. Figure 5-6 shows the physical picture of the 2,800-ton multilayer press.

|

|

2. Laminating Process

1. Tape Cutting and Stacking

Tape cutting is to cut the tape to a certain size (press size). The cutting equipment can be a continuous fixed-length slicer or manual cutting. The cutting of tape requires accurate size, not too long or too short. Stack the cut tape neatly, stack tapes with different glue content and fluidity separately, mark them and store them for later use. In order to avoid the increase of the volatile content of the tape and the decrease of the soluble resin content as much as possible, the tape should be stored in a dry room.

The cutting methods of dipping cloth for different purposes are also different: the tape used for lamination is cut according to the production specifications, while leaving a margin for processing burrs; the tape used for tape winding is first cut into the tape required for winding molding The tape is then used by sewing, overlapping, rewinding, and rolling into a tape reel with a certain diameter.

The process of arranging the adhesive tape is very important to the quality of the laminate. If it is improperly assembled, the laminate will be cracked and the surface spattered will occur. Therefore, the following points should be paid attention to in specific operations:

On the surface layer of the laminated board, 2 to 3 sheets of surface tape should be placed on each side, and its glue content and fluidity should be slightly higher than that of the lining.

The volatile content should not be too large. If the volatile content is too large, it should be dried before use; otherwise, the electrical properties and heat resistance of the product will be affected, and corner bubbles and flax will be easily generated.

Calculation of matching. To make the thickness of the pressed plate accurate, the quality method is generally used to determine the amount of tape for the plate. The quality of the tape (or tape) material required for each board is related to the thickness, area, density of the laminated board, and the rate of cutting off the edge after the board.

2. Hot Pressing Process

Push the combination of the charging car into the middle of the hot plate of the multi-layer press, the hot plate rises slowly, and pressurizes into steam to suppress after closing.

The key to the pressing process is to determine the process parameters, of which the most important parameters are temperature, pressure and time. The pressure system firstly depends on the variety and nature of the material, and secondly considers the product thickness, board area and equipment conditions.

Temperature

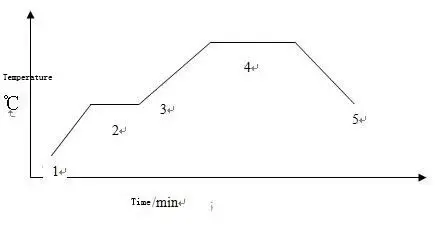

The heating process of the general pressing process can be divided into 5 stages

|

|

Pressure

The function of pressure is to overcome the vapor pressure of the volatiles, to make the bonding resin flow, and to make the rubber cloth layers closely contact, and to prevent the plate from being deformed when it is cooled.

The size of the molding pressure is determined according to the curing characteristics of the resin. If small molecules escape during curing, the pressure should be higher; when the curing temperature of the resin is high, the molding pressure should be increased accordingly. The size of the molding pressure also needs to consider factors such as the thickness of the product, the rubber content of the tape and the heating rate.

|

Name of Board Process parameters |

3230 Phenolic resin Board |

Phenolic modified diphenyl ether board |

|||

|

Pressing process |

Timing of pressurization |

(110~120) °C,6MPa,15min |

80°C, (7~9) MPa |

(130~150) °C, 3MPa, (30~50) min |

(110~120) °C, 6MPa, 15min |

|

Molding temperature and pressure |

160°C, 6MPa |

160℃, pressure keeping |

160°C, 6MPa |

160°C, 6MPa |

|

|

Holding time |

5~8min/mm |

8min/mm |

5~8min/mm |

5~8min/mm |

|

|

Demold |

Room temperature demolding |

Room temperature demolding |

Room temperature demolding |

Room temperature demolding |

|

Timing

The time from the start of preheating and pressing to taking out the product is the pressing time. It is the sum of the pre-pressing, hot pressing and cooling time. The pressing time is related to the curing speed of the resin, the thickness of the laminate and the pressing temperature. Whether it is fully cured is the basis.

The pre-pressing time depends on the properties of the tape. If the tape has a high insoluble resin content and a low volatile content, the pre-pressing time will be short, and vice versa. The hot pressing time is to ensure that the resin in the tape is fully cured. If it is too short, the resin will not be cured completely, and if it is too long, the product performance will decrease, which needs to be determined through repeated trials. Cooling time is the last link to ensure product quality. If the cooling time is too short, it will easily cause the product to warp and crack; if it is too long, it will reduce production efficiency.

1. Cooling Demolding

After the heat preservation is over, the heat source can be turned off, and the temperature can be cooled naturally or with cold air, cold water, etc., but the pressure should not be reduced too early, otherwise the surface of the product will be blistered or warped. The demolding temperature is generally lower than 60°C.

2. Post-Processing

The purpose of post-treatment is to further cure the resin until it is completely cured, while partially eliminating the stress in the product and improving the performance of the product. The post-treatment of epoxy board and epoxy phenolic board is 120-150 minutes in an environment with a temperature of 120-130°C, which can improve the mechanical and electrical properties of the product.