Is an FR4 Epoxy Sheet suitable for PCBs?

2024-06-04 14:04:53

Is an FR4 Epoxy Sheet Suitable for PCBs?

Introduction to FR4 Epoxy Sheets

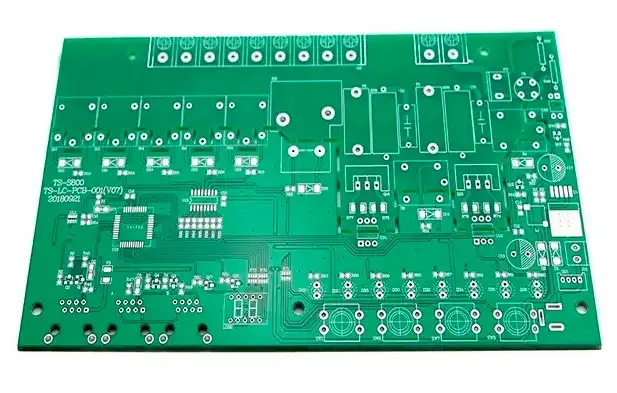

Epoxy Resin Sheets stand as a foundation in the assembling of printed circuit sheets (PCBs), famous for their uncommon electrical protection properties, hearty mechanical strength, and cost-viability. Made out of woven glass fiber texture impregnated with an epoxy sap fastener, FR4 is commended for its capacity to convey solid execution across a different scope of electronic applications.

The woven glass fiber texture inside FR4 epoxy sheets adds to their astounding mechanical strength, furnishing the PCBs with the versatility expected to get through different anxieties and natural circumstances. This heartiness not just guarantees the uprightness of the PCB during assembling cycles and get together yet additionally reinforces its toughness all through its functional life expectancy. Besides, the innate fire retardancy of FR4 further upgrades the security and dependability of the PCBs, making them reasonable for applications where imperviousness to fire is a basic thought.

Notwithstanding their mechanical properties, FR4 epoxy sheets succeed in giving great electrical protection, really forestalling electrical spillage and guaranteeing signal honesty inside the PCB. This protection capacity is crucial for keeping up with the usefulness and dependability of electronic circuits, especially in high-recurrence or high-voltage applications.

Moreover, the reasonableness of FR4 epoxy sheets goes with them a favored decision for PCB fabricating, offering a convincing equilibrium between execution and cost-viability. This availability permits makers to deliver great PCBs without settling on fundamental credits like electrical protection and mechanical solidness, improving the general incentive of electronic gadgets and frameworks.

Generally, the broad reception of FR4 epoxy sheets in PCB producing is a demonstration of their capacity to meet the severe prerequisites of present day electronic applications, enveloping electrical execution, mechanical strength, fire retardancy, and cost-effectiveness. Their adaptability and unwavering quality make FR4 epoxy sheets an irreplaceable part in the formation of electronic gadgets, supporting their critical job in progressing mechanical development and progress.

Advantages of FR4 for PCB Use

The expense adequacy and wide accessibility of Epoxy Resin Sheets pursue them an uncommonly engaging decision for printed circuit board (PCB) fabricating. Their minimal expense, combined with a powerful store network that upholds huge scope creation needs, positions FR4 as a favored material for delivering excellent PCBs. This monetary benefit empowers makers to make reliable electronic items without blowing up creation costs, adding to the reasonableness and availability of electronic gadgets on the lookout.

Notwithstanding its expense viability, FR4's remarkable electrical protection properties and mechanical strength put it aside as a flexible and dependable material for PCBs. The high dielectric strength of FR4 guarantees successful electrical protection, assuming a basic part in keeping up with signal respectability and limiting the gamble of electrical breakdowns. This property is especially vital for electronic circuits working at high frequencies or voltages, where keeping up with protection honesty is fundamental for the usefulness and dependability of the PCB.

Additionally, the consolidation of glass support inside FR4 epoxy sheets gives the material extraordinary mechanical strength, delivering it impervious to actual burdens like effects and vibrations. This vigor upgrades the flexibility of PCBs, guaranteeing their capacity to endure different ecological circumstances and mechanical burdens, eventually broadening the functional life expectancy of electronic gadgets.

Besides, FR4 displays noteworthy warm and dampness obstruction, permitting it to endure an expansive scope of temperatures and natural circumstances. Indicated to perform ideally between - 40°C to 130°C, FR4 stays stable under warm pressure up to its glass progress temperature (Tg). Its protection from dampness further improves its strength, making it reasonable for applications presented to differing ecological circumstances, including stickiness and clamminess.

Limitations of FR4 PCB Materials

In spite of its far and wide use, FR4 epoxy sheets have specific constraints, especially in high-recurrence or high-temperature applications. Understanding these impediments is significant for choosing the most reasonable materials for explicit electronic plans and working circumstances.

In high-recurrence applications, FR4's electrical properties can show varieties with recurrence, possibly affecting impedance strength. This changeability makes FR4 less great for high-recurrence or high level RF and microwave applications, where materials with more reliable and stable dielectric properties are liked. In these situations, particular materials intended to keep up with exact electrical qualities across an expansive recurrence range are much of the time decided to guarantee ideal execution and sign respectability in high-recurrence circuits.

Moreover, while FR4 exhibits flexibility in moderate temperature ranges, it may not be the most appropriate decision for conditions where temperatures surpass 130°C. In such high-temperature situations, materials designed to endure raised temperatures without encountering corruption or compromised execution ought to be thought of. These specific materials can offer the warm soundness and dependability expected to guarantee the life span and usefulness of electronic parts and frameworks working in requesting warm conditions.

Recognizing these limits is fundamental for architects and fashioners while choosing materials for explicit electronic applications. By understanding the requirements of FR4 in high-recurrence and high-temperature conditions, experts can settle on informed conclusions about material determination, picking choices that can convey the important presentation and unwavering quality under testing working circumstances.

Design Considerations When Using FR4

While planning printed circuit sheets (PCBs) utilizing Epoxy Resin Sheets, cautious thought of the material's thickness and construction is fundamental to accomplish ideal mechanical honesty and electrical execution. These choices altogether impact the usefulness, dependability, and manufacturability of the PCB, making them basic parts of the plan cycle.

The thickness of the FR4 sheet assumes an essential part in deciding the mechanical strength and unbending nature of the subsequent PCB. Thicker FR4 sheets offer expanded underlying scaffolding, which can be favorable for applications requiring improved solidness and protection from actual stressors like bowing and vibration. Nonetheless, thicker FR4 sheets may likewise add to higher assembling costs and expanded board weight, factors that should be adjusted against the particular necessities of the planned application.

Additionally, the decision of FR4 thickness impacts the electrical exhibition of the PCB, especially as far as sign respectability and impedance control. More slender FR4 sheets might display different electrical attributes contrasted with thicker ones, influencing variables like trademark impedance and sign weakening. Subsequently, choosing the suitable FR4 thickness is pivotal for accomplishing the ideal electrical properties and guaranteeing reliable sign transmission inside the PCB.

Notwithstanding material thickness, the plan of copper follows and warm administration techniques are necessary contemplations while working with FR4-based PCBs. The width and design of copper follows on the PCB surface straightforwardly influence signal transmission, power conveyance, and electromagnetic obstruction (EMI) control. Cautious streamlining of follow widths and steering designs is important to keep up with signal trustworthiness and limit misfortunes in rapid computerized or high-recurrence simple circuits.

Moreover, successful warm administration methodologies, for example, the utilization of intensity sinks, warm vias, and legitimate part situation, are imperative for guaranteeing the drawn out dependability of FR4-based PCBs, particularly in applications where warm dissemination is a worry. By effectively overseeing heat scattering, fashioners can forestall unnecessary temperature development, which can adversely affect the exhibition and life expectancy of electronic parts and the general unwavering quality of the PCB get together.

Conclusion and Call to Action

All in all, FR4 epoxy sheets offer a reasonable cluster of elements that make them reasonable for a wide scope of PCB applications, however for certain provisos in high-recurrence and high-temperature conditions. For those hoping to use the benefits of FR4 in PCB fabricating, guaranteeing similarity with your particular application prerequisites is vital.

For master direction on choosing the right materials for your PCB projects and to exploit an expert assembling provider with an enormous stock, complete certificates, and quick conveyance choices, reach us at info@jhd-material.com. Our GMP-consistent offices and backing for OEM customization go with us a top decision for worldwide purchasers looking for dependable and excellent electronic part producing.