Selection of epoxy resin in prepreg

2023-02-21

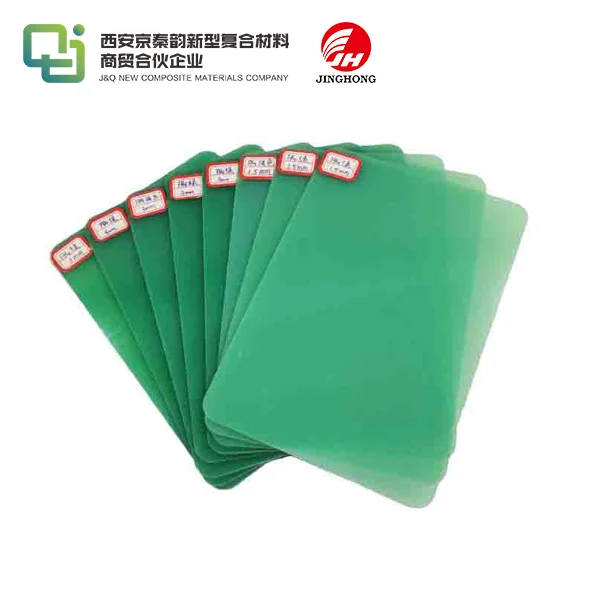

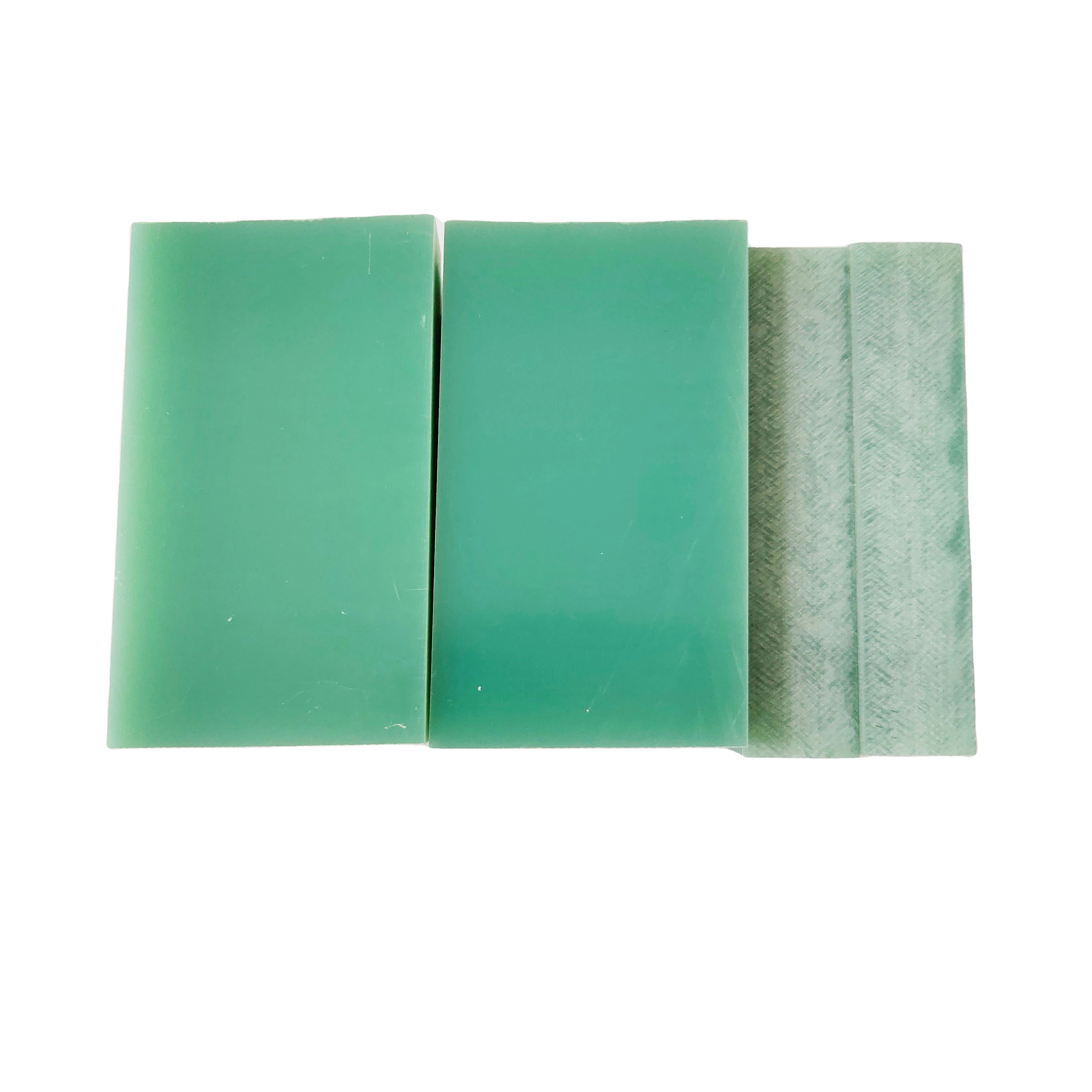

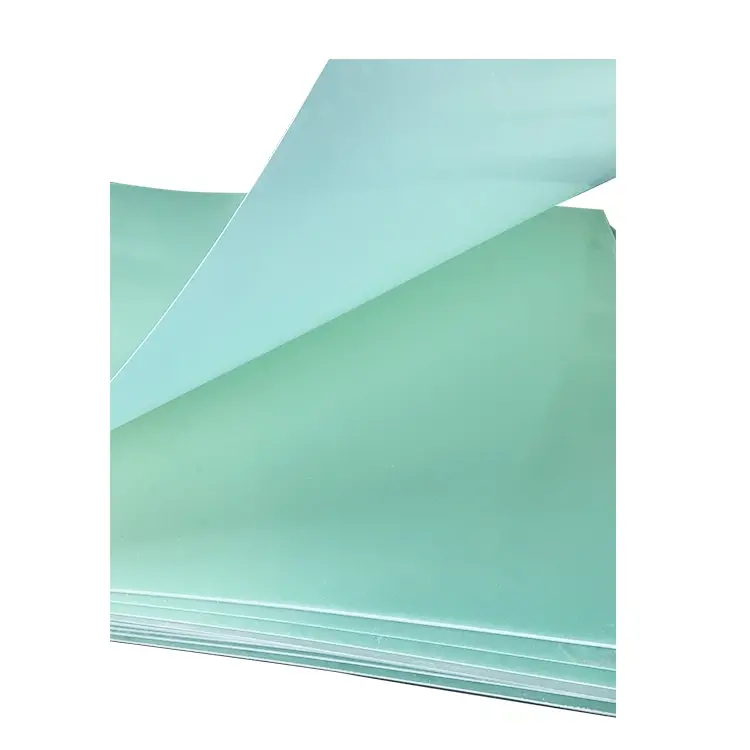

Prepreg usually refers to the intermediate of drying or prepolymerization of the fiber or its fabric impregnated with resin system used for manufacturing resin matrix composites. The prepreg sheet product made by impregnating the reinforcing fiber in the resin matrix is the intermediate material of the composite material. The prepreg sheet is one of the most important raw material of FR4 sheet, 3240 epoxy sheet, and bakelite sheet.

Reinforcing materials generally include:

Carbon fiber, glass fiber, polyethylene fiber, and aromatic polyamide fiber.

The matrix resin generally includes:

Epoxy resin, polyester resin, vinyl resin, cyanate ester, thermoplastic resin, etc.

The composite produced by using prepreg can improve the strength, hardness, corrosion resistance, fatigue life, wear resistance and impact resistance of the material, make it lighter and have a certain storage period and other characteristics.

The production methods of prepreg include hot-melt method and solution impregnation method. The hot-melt method refers to heating the matrix resin directly to reduce the viscosity and make it evenly distributed in the middle of the fiber. The resin content of the hot-melt method is easy to control and does not contain solvent, but when the resin viscosity is high, the fiber is easy to deform. The solution impregnation method refers to dissolving the resin in the solvent to reduce the viscosity, and then heating the resin to volatilize the solvent after it contains the fiber. The solution impregnation method is low in cost and simple in manufacture, but the solvent is easy to pollute and may affect the strength of the material during volatilization.

At present, prepreg is one of the mainstream materials in composite molding technology. In prepreg, epoxy resin is the main matrix resin. The epoxy resin completely impregnates the fiber material in the liquid state, and after partial curing, the resin changes from liquid state to solid state. Because the resin is not fully cured, the prepreg needs to be stored in a low temperature environment. When it is to be used, it is processed by molding process, and then raised to high temperature again until it is fully cured.

Epoxy resins used in prepreg include:

NPEL-128 (Epoxy Resin e51)

Epoxy equivalent (g/eq): 184~190

Viscosity (cps/25 ℃): 12000~15000

Product description: Universal standard bisphenol A epoxy resin.

NPSN-901 × seventy-five

Epoxy equivalent (g/eq): 450~500

Viscosity (cps/25 ℃): 8000~15000

Product description: solvent-based bisphenol A epoxy resin, containing 25% Xylene solvent.

NPPN-638S

Epoxy equivalent (g/eq): 170~190

Product description: general phenolic epoxy resin.

NPEF-170

Epoxy equivalent (g/eq): 160~180

Viscosity (cps/25 ℃): 2000~5000

Product description: standard bisphenol F epoxy resin.

In recent years, prepreg is widely used in composite materials of aerospace, wind power, rail transit, pipeline and sports and leisure products. It has a more mature and broad application prospect in national production and life.