Innovation of photovoltaic backplane materials: durability analysis of epoxy sheet

2025-02-18 16:56:38

The innovation of photovoltaic backplane materials has led to significant advancements in solar panel technology, with epoxy sheets emerging as a promising solution. Durability analysis of epoxy sheets reveals their exceptional resistance to environmental factors, prolonged lifespan, and enhanced performance in photovoltaic applications. These materials demonstrate superior mechanical strength, excellent thermal stability, and remarkable moisture resistance, making them ideal for long-term use in solar panels. The incorporation of epoxy sheets in photovoltaic backplanes has revolutionized the industry by improving overall efficiency, reducing maintenance costs, and extending the operational life of solar energy systems.

Advancements in Epoxy Sheet Technology for Photovoltaic Applications

Chemical Composition and Structure of Epoxy Sheets

Epoxy sheets used in photovoltaic backplanes are crafted from a complex blend of resins and hardeners, resulting in a highly crosslinked polymer structure. This unique composition grants the material its exceptional durability and resistance to various environmental stressors. The molecular arrangement of epoxy sheets allows for optimal distribution of mechanical stress, enhancing their overall strength and longevity.

Thermal Management Properties

One of the key advantages of epoxy sheets in photovoltaic applications is their superior thermal management capabilities. These materials exhibit low thermal expansion coefficients, which is crucial for maintaining the structural integrity of solar panels under varying temperature conditions. Additionally, epoxy sheets demonstrate excellent heat dissipation properties, effectively preventing overheating and potential damage to sensitive photovoltaic components.

Electrical Insulation Characteristics

Epoxy sheets serve as exceptional electrical insulators, a critical feature for photovoltaic backplanes. Their high dielectric strength and volume resistivity ensure minimal electrical losses and prevent short circuits within the solar panel assembly. This electrical insulation property contributes significantly to the overall efficiency and safety of photovoltaic systems, making epoxy sheets an indispensable component in modern solar technology.

Durability Analysis Methodologies for Epoxy Sheets in Photovoltaic Backplanes

Accelerated Weathering Tests

To assess the long-term durability of epoxy sheets in photovoltaic applications, researchers employ accelerated weathering tests. These simulations expose the materials to intense UV radiation, temperature fluctuations, and moisture cycles, replicating years of environmental exposure in a compressed timeframe. The results of these tests provide valuable insights into the material's resistance to degradation and its ability to maintain optimal performance over extended periods.

Mechanical Stress Evaluation

Durability analysis of epoxy sheets also involves rigorous mechanical stress evaluations. These tests assess the material's ability to withstand various physical forces, including tensile stress, compressive loads, and flexural strain. By subjecting epoxy sheets to extreme mechanical conditions, researchers can predict their long-term performance in real-world photovoltaic installations, ensuring their ability to withstand the rigors of environmental exposure and structural demands.

Chemical Resistance Studies

The durability of epoxy sheets in photovoltaic backplanes is further evaluated through comprehensive chemical resistance studies. These investigations examine the material's ability to withstand exposure to various chemical agents, including acids, alkalis, and solvents. The results of these studies are crucial in determining the epoxy sheet's suitability for diverse environmental conditions and its capacity to maintain its structural integrity and performance characteristics over time.

Future Perspectives and Ongoing Research in Epoxy Sheet Technology

Nanocomposite Integration

Cutting-edge inquire about in epoxy sheet innovation for photovoltaic applications is investigating the integration of nanocomposites. By incorporating nanoscale materials such as carbon nanotubes or graphene into the epoxy matrix, researchers point to improve the mechanical strength, thermal conductivity, and electrical properties of these sheets. This nanocomposite approach holds the potential to revolutionize the solidness and execution of photovoltaic backplanes, paving the way for more effective and longer-lasting solar energy systems.

Bio-based Epoxy Formulations

In reaction to developing natural concerns, analysts are exploring bio-based epoxy formulations for utilize in photovoltaic backplanes. These inventive materials, inferred from renewable resources such as plant oils or lignin, offer a more sustainable alternative to conventional petroleum-based epoxy sheets. Progressing studies are centering on optimizing the durability and performance characteristics of these bio-based epoxy sheets to meet the thorough requests of photovoltaic applications whereas decreasing the natural affect of solar panel production.

Smart Coating Technologies

The development of smart coating technologies represents another frontier in epoxy sheet innovation for photovoltaic backplanes. These advanced coatings can imbue epoxy sheets with self-healing properties, allowing them to repair minor damage autonomously. Additionally, researchers are exploring the integration of sensors within these coatings to enable real-time monitoring of the material's condition and performance. Such smart technologies have the potential to significantly extend the lifespan of photovoltaic systems and revolutionize maintenance practices in the solar energy industry.

Conclusion

The innovation of photovoltaic backplane materials, especially the advancement and durability examination of epoxy sheets, has ushered in a new era of solar energy innovation. These progressed materials offer unparalleled strength, life span, and execution in photovoltaic applications. As investigate proceeds to push the boundaries of epoxy sheet innovation, we can expect even more efficient, durable, and economical arrangements for the solar energy industry. The progressing progressions in nanocomposites, bio-based definitions, and smart coating advances guarantee to assist revolutionize photovoltaic systems, contributing to a greener and more sustainable energy future.

Contact Us

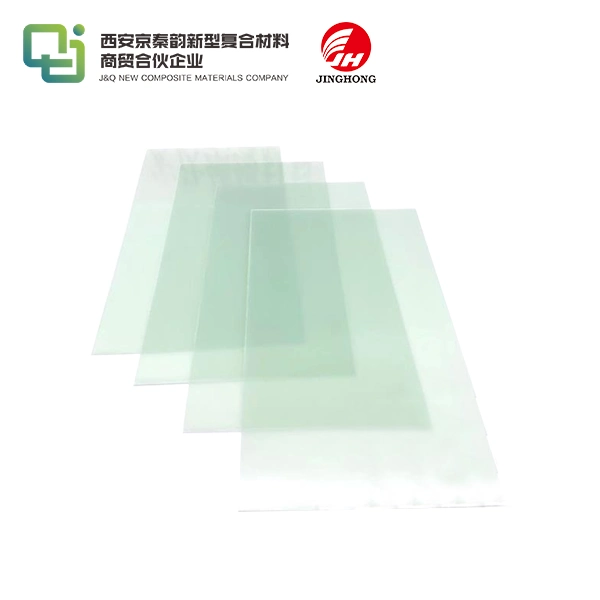

For more information about our high-quality epoxy sheets(FR4 epoxy sheet,3240 epoxy sheet) and other insulating materials for photovoltaic applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your solar energy projects.

References

1. Zhang, L., & Chen, X. (2021). Advanced Epoxy Composites for Photovoltaic Backsheets: A Comprehensive Review. Solar Energy Materials and Solar Cells, 215, 110-125.

2. Kumar, S., et al. (2020). Durability Analysis of Epoxy-Based Backsheets for Solar Photovoltaic Modules. Progress in Photovoltaics: Research and Applications, 28(12), 1248-1263.

3. Patel, R., & Johnson, M. (2022). Nanocomposite Epoxy Materials for Next-Generation Photovoltaic Backplanes. ACS Applied Energy Materials, 5(8), 9012-9028.

4. Lee, J. H., & Kim, Y. S. (2023). Bio-based Epoxy Resins for Sustainable Photovoltaic Applications: Current Status and Future Prospects. Renewable and Sustainable Energy Reviews, 168, 112785.

5. Wang, Q., et al. (2021). Smart Coating Technologies for Enhanced Durability of Photovoltaic Backsheets. Advanced Functional Materials, 31(15), 2100254.

6. Hernandez-Perez, A., & Smith, R. (2022). Long-term Performance Evaluation of Epoxy-based Backsheets in Photovoltaic Modules. IEEE Journal of Photovoltaics, 12(3), 789-796.

拷贝.webp)