How to match the insulating materials and electromagnetic wires in the motor windings more reasonably?

2023-01-06

Temperature rise is an important performance index of motor products. The temperature rise of motor windings and the temperature during actual operation put forward specific performance requirements for the matching electromagnetic wires and insulation materials, that is, under the normal working conditions of the motor, the insulation materials should not have abnormal performance degradation, and the insulation layer of electromagnetic wires used for windings should not have adverse effects such as qualitative change or falling off.

During the long-term use of insulation materials, the insulation performance will gradually deteriorate under the effects of temperature, electrical, mechanical and other aspects, which is called insulation aging. The temperature has a great influence on the service life and insulation aging of insulating materials. Therefore, in order to ensure the long-term safe operation of the motor, the heat resistance grade and limit operating temperature of insulating materials are clearly specified. If the working temperature of the motor exceeds the limit working temperature of the insulating material used, the service life of the insulating material will be shortened.

Medium and small three-phase asynchronous motors are mainly insulated with class B and class F. Especially in recent years, class F and class H insulation have developed rapidly. The insulation structure of the basic series of class F three-phase asynchronous motors uses new class slot insulation materials to strengthen turn to turn insulation, that is, electromagnetic wires with high heat resistance are used. The traction motor has basically reached Class H insulation and is developing to a higher insulation level.

From the actual operating conditions, in order to further improve the reliability of the motor, most power frequency and variable frequency low-voltage motors have been designed according to the insulation not lower than Class F.

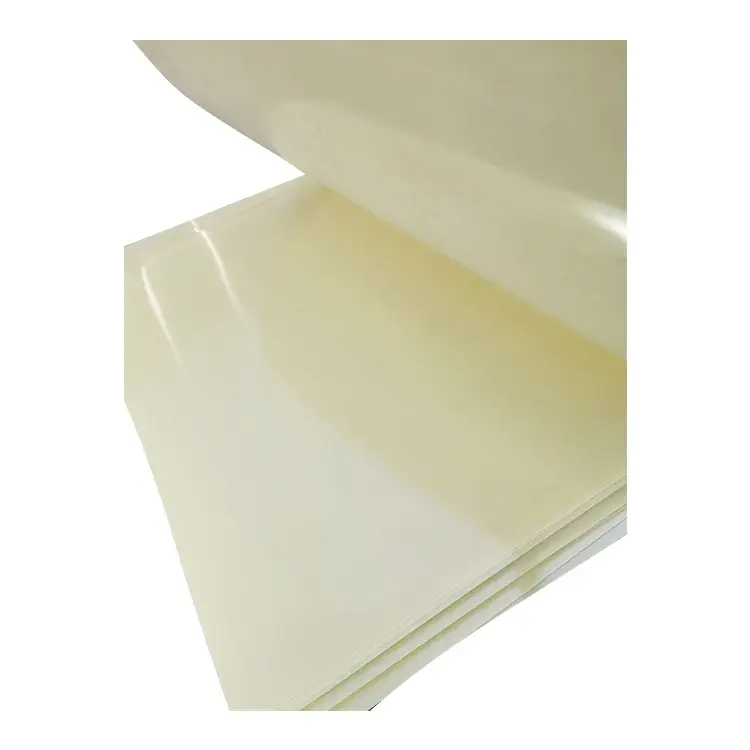

In the insulation structure of Class F low-voltage motor, the slot insulation is generally made of 6640, 6641, 6642, 6643 and other composite materials, and the electromagnetic wire should reach Class 155 heat resistance grade; Most of the insulated hoses matched with the windings are 2740 and 2750. In the cold northern climate, 2760 may be required to prevent the hose from breaking due to excessive stiffness during processing. Under this insulation level, 3240 epoxy sheet pull slot wedge is generally used. Similarly, the insulating paint during insulation treatment shall also meet the requirements of relevant temperature resistance grade.