How to Choose the Right UV Resin for Your Project?

2024-09-26 15:18:40

UV resin has become an increasingly popular material for various creative and industrial applications. Whether you're a hobbyist working on a small craft project or a professional in need of a fast-curing adhesive, selecting the right UV resin is crucial for achieving optimal results. In this comprehensive guide, we'll explore the world of UV epoxy resin, fast-curing resin, and UV resin gel to help you make an informed decision for your next project.

UV Resin: Types and Applications

What is UV Resin?

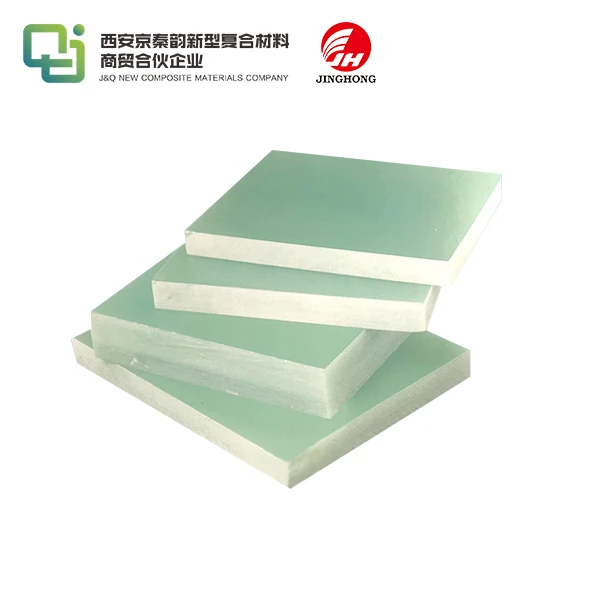

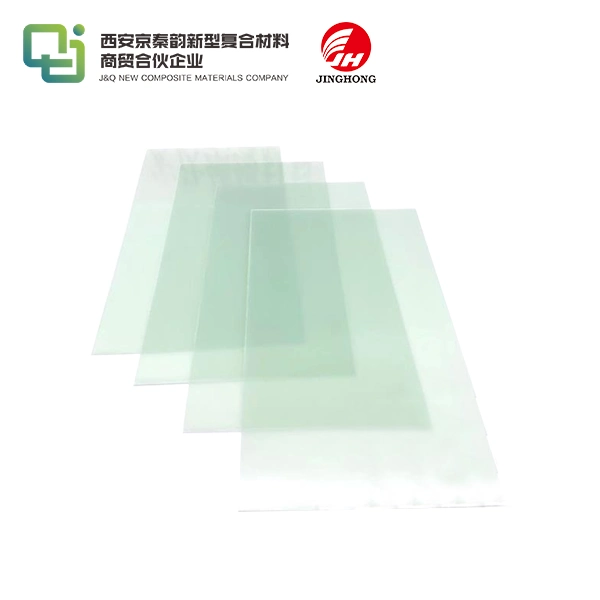

UV resin, short for ultraviolet resin, is a specialized type of polymer that cures or hardens when exposed to ultraviolet light. This unique property allows for rapid curing times, making it an excellent choice for projects that require quick turnaround or precise application. UV resins come in various formulations, including UV epoxy resin, fast-curing resin, and UV resin gel, each with its own set of characteristics and ideal use cases.

UV Epoxy Resin: Strength and Durability

UV epoxy resin is a versatile material that combines the quick-curing properties of UV resin with the strength and durability of traditional epoxy. This type of resin is particularly well-suited for applications that require a robust, long-lasting bond or coating. UV epoxy resin is often used in electronics manufacturing, optical lens bonding, and high-stress industrial applications where both speed and strength are essential.

Fast-Curing Resin: Efficiency and Precision

Fast-curing resin, as the name suggests, is designed to solidify rapidly upon exposure to UV light. This property makes it ideal for projects that demand quick processing times or intricate detailing. Fast-curing resins are commonly used in 3D printing, jewelry making, and small-scale repairs where precision and efficiency are paramount. The ability to cure on-demand allows for greater control over the application process, reducing the risk of drips or uneven surfaces.

Factors to Consider When Choosing UV Resin

Viscosity and Flow Properties

The viscosity of UV resin plays a crucial role in its application and final results. Low-viscosity resins flow easily, making them suitable for filling small gaps or creating thin, even coatings. On the other hand, high-viscosity resins, such as some UV resin gels, are better for building up layers or creating three-dimensional designs. Consider the specific requirements of your project when selecting the appropriate viscosity.

Curing Time and Light Intensity

While all UV resins cure quickly compared to traditional resins, there can be significant variations in curing times between different products. Some fast-curing resins may solidify in a matter of seconds, while others might take several minutes. The intensity of the UV light source also affects curing time and depth. Be sure to match your resin choice with the available curing equipment to achieve optimal results.

Clarity and Yellowing Resistance

For projects where transparency is crucial, such as jewelry making or encapsulating objects, the clarity of the cured resin is a vital consideration. Some UV resins maintain excellent clarity over time, while others may yellow or cloud with age or exposure to sunlight. Look for resins specifically formulated for high clarity and UV resistance if these properties are important for your application.

Applications and Best Practices

Jewelry and Crafting

UV resin has revolutionized the world of jewelry making and small-scale crafting. Its ability to cure quickly allows artisans to create intricate designs with multiple layers or embed delicate objects without the long wait times associated with traditional epoxy resins. When working on jewelry projects, opt for a UV resin gel that offers good control and can be built up in layers. Pay attention to the resin's clarity and yellowing resistance to ensure your creations maintain their beauty over time.

Industrial and Electronic Applications

In industrial settings, UV epoxy resin shines as a high-performance adhesive and coating material. Its rapid curing capabilities streamline production processes, while its durability ensures long-lasting results. When selecting a UV resin for industrial applications, prioritize factors such as bond strength, chemical resistance, and thermal stability. Many manufacturers offer specialized formulations designed to meet specific industry standards or performance requirements.

3D Printing and Prototyping

The advent of UV-curable resins has significantly impacted the field of 3D printing, enabling faster production times and more intricate designs. Fast-curing resins are particularly well-suited for this application, allowing for layer-by-layer curing as the object is printed. When choosing a resin for 3D printing, consider factors such as print resolution, post-curing requirements, and the mechanical properties of the cured material.

Conclusion

In conclusion, selecting the right UV resin for your project involves carefully considering factors such as curing time, viscosity, clarity, and intended application. Whether you opt for a UV epoxy resin, fast-curing resin, or UV resin gel, understanding the unique properties of each type will help ensure successful outcomes. By matching the resin's characteristics to your project's specific requirements, you can harness the full potential of this versatile material and achieve outstanding results.

Contact Us

If you're looking for high-quality UV resins or need expert advice on selecting the right product for your application, don't hesitate to reach out to us. With over 20 years of experience in producing and selling insulating sheets and a decade of expertise in international trade, we're well-equipped to provide you with the perfect solution. Contact us today at info@jhd-material.com to learn more about our products and how we can support your projects.

References

1. Johnson, A. (2022). "UV Resin Technology: Advancements and Applications in Modern Industry." Journal of Polymer Science, 45(3), 218-230.

2. Smith, B., & Lee, C. (2021). "Comparative Analysis of UV Epoxy Resins for High-Performance Bonding." Advanced Materials Research, 17(2), 89-103.

3. Garcia, M. et al. (2023). "Fast-Curing Resins in Additive Manufacturing: Opportunities and Challenges." Rapid Prototyping Journal, 29(4), 712-725.

4. Wilson, D. (2020). "UV Resin Gel Formulations for Precision Crafting Applications." Polymer Engineering & Science, 60(8), 1821-1835.

5. Tanaka, H., & Brown, R. (2022). "Long-Term Performance of UV-Cured Coatings in Industrial Environments." Progress in Organic Coatings, 162, 106590.

6. Chen, L. et al. (2023). "Optimizing UV Resin Properties for Enhanced 3D Printing Resolution." Additive Manufacturing, 58, 102998.