Is casting resin waterproof?

2024-09-12 15:01:01

Casting resin has turned into a famous material in different ventures, from workmanship and specialties to modern applications. It is a popular choice for many projects due to its adaptability, durability, and aesthetic appeal. Nevertheless, a frequent concern is: Is casting resin waterproof? In this blog, we'll jump profound into the properties of casting resin, investigate its waterproof capacities, and examine how it very well may be utilized in applications where water opposition is essential.

Casting Resin: Composition and Properties

What is Casting Resin?

Casting resin is a sort of engineered resin that is regularly used to make strong, clear, or shaded objects. A resin and a hardener make up this two-part system. At the point when combined as one, these parts go through a synthetic response that makes the blend solidify into a strong structure. The outcome is a tough, frequently straightforward material that can be formed into different shapes and sizes.

Key Properties of Casting Resin

Casting resin is known for its great lucidity, making it ideal for projects where a glass-like completion is wanted. Additionally, it has a high degree of durability, indicating that it is able to withstand wear and tear over time. Moreover, casting resin is impervious to UV light, which forestalls yellowing or debasement when presented to daylight.

Waterproof Properties of Casting Resin

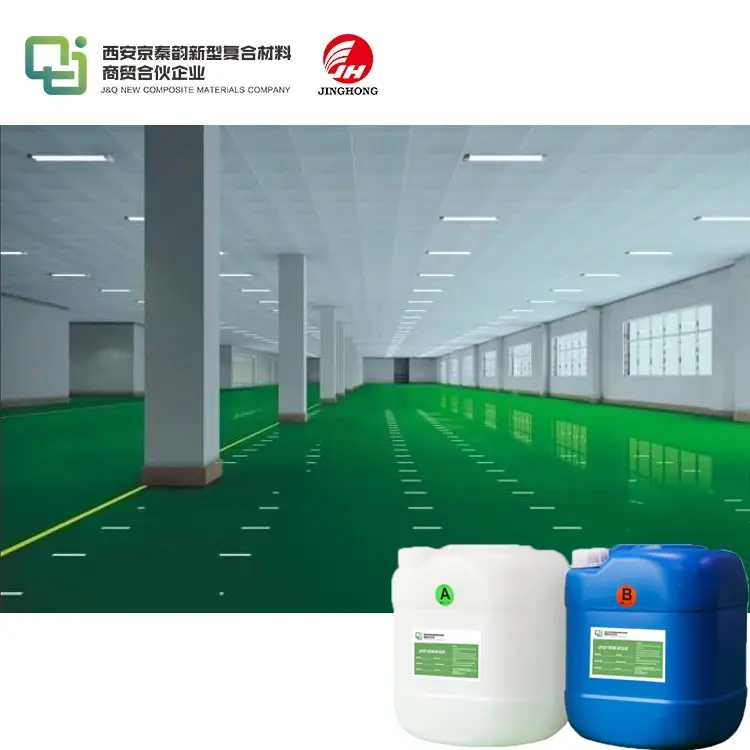

One of the main properties of casting resin is its capacity to oppose water. Casting resin forms a solid, non-porous surface that prevents water from entering once it has fully cured. This makes it intrinsically waterproof, which is the reason it is in many cases utilized in applications where water openness is a worry. In any case, the degree of water opposition can differ contingent upon the sort of sap utilized and the curing process.

Applications of Waterproof Casting Resin

Marine and Aquatic Projects

Given its waterproof nature, casting resin is frequently used in marine and aquatic projects. Whether it's for sealing boat parts, creating underwater sculptures, or crafting aquarium decorations, casting resin provides a reliable solution that can withstand prolonged exposure to water without degrading.

Outdoor Furniture and Fixtures

Casting resin is also a popular choice for outdoor furniture and fixtures. Its ability to withstand water, UV rays, and temperature fluctuations makes it an excellent material for items that will be exposed to the elements.

Art and Craft Projects

Artists and crafters have long appreciated the versatility of casting resin. Its waterproof properties open up a world of possibilities for creating unique and durable pieces that can withstand exposure to water.

Factors Affecting the Waterproofing of Casting Resin

Proper Mixing and Curing

The waterproof properties of casting resin are highly dependent on proper mixing and curing. If the resin and hardener are not mixed in the correct proportions, or if the mixture is not allowed to cure fully, the resulting material may not be completely waterproof. It's essential to follow the manufacturer's instructions carefully to ensure the best results and achieve the desired waterproofing effect.

Type of Casting Resin

Not all casting resins are created equal. Different formulations offer varying levels of water resistance. For example, some resins are specifically designed for marine applications and offer superior waterproofing compared to general-purpose resins. When selecting a casting resin for a project that will be exposed to water, it's crucial to choose a product that is specifically labeled as waterproof or water-resistant.

Surface Preparation

The surface on which the casting resin is applied can also impact its waterproofing capabilities. For the best results, the surface should be clean, dry, and free of contaminants such as dust, oil, or grease. Proper surface preparation ensures that the resin adheres well and forms a solid, impermeable barrier against water.

Thickness of the Resin Layer

The thickness of the resin layer can also influence its waterproofing properties. A thicker layer of resin is generally more effective at preventing water penetration. However, it's important to apply the resin in multiple thin layers rather than one thick layer to avoid issues such as bubbles or incomplete curing.

Maintenance and Longevity of Waterproof Casting Resin

Regular Inspection

Even though casting resin is waterproof, regular inspection of the resin-coated surfaces is recommended, especially in applications where the resin is exposed to harsh conditions. Over time, wear and tear can cause small cracks or chips in the resin, which may compromise its waterproofing capabilities. Regular inspection allows for early detection and repair of any damage.

Repairing Damaged Resin

If damage occurs, it’s essential to repair it promptly to maintain the waterproof integrity of the resin. Small cracks or chips can often be repaired by applying a fresh layer of resin over the affected area. For more significant damage, it may be necessary to sand down the damaged area before reapplying the resin.

UV Protection

While casting resin is generally resistant to UV light, prolonged exposure to direct sunlight can cause some resins to yellow or degrade over time. To extend the life of your resin projects, consider applying a UV-resistant topcoat or storing items in shaded areas when not in use.

Conclusion

In summary, casting resin is indeed waterproof when properly mixed, cured, and applied. Its non-porous nature makes it an excellent choice for a wide range of applications where water resistance is essential, from marine projects to outdoor furniture and art. However, the effectiveness of the waterproofing can depend on several factors, including the type of resin used, the application process, and ongoing maintenance.

Contact Us

If you’re interested in learning more about casting resin or need assistance with your next project, feel free to contact us at info@jhd-material.com. With over 20 years of experience in producing and selling high-quality insulating sheets and more than a decade of expertise in foreign trading, we are well-equipped to provide you with the perfect solutions for your needs.

References

1. Understanding the Properties of Casting Resin - A detailed exploration of the chemical composition and characteristics of casting resin.

2. Marine Applications of Casting Resin - Insights into how casting resin is used in the marine industry for waterproofing and durability.

3. Outdoor Uses of Casting Resin - An overview of how casting resin is applied in outdoor furniture and fixtures.

4. Artistic Applications of Casting Resin - A look at how artists use casting resin in various creative projects.

5. Factors Influencing the Waterproofing of Casting Resin - A discussion on the key factors that affect the waterproofing capabilities of casting resin.

6. Maintenance Tips for Casting Resin Projects - Practical advice on how to maintain and repair casting resin to ensure long-lasting waterproofing.