How Durable Is Phenolic Paper Laminate in High-Temperature Environments?

2024-07-12 15:18:06

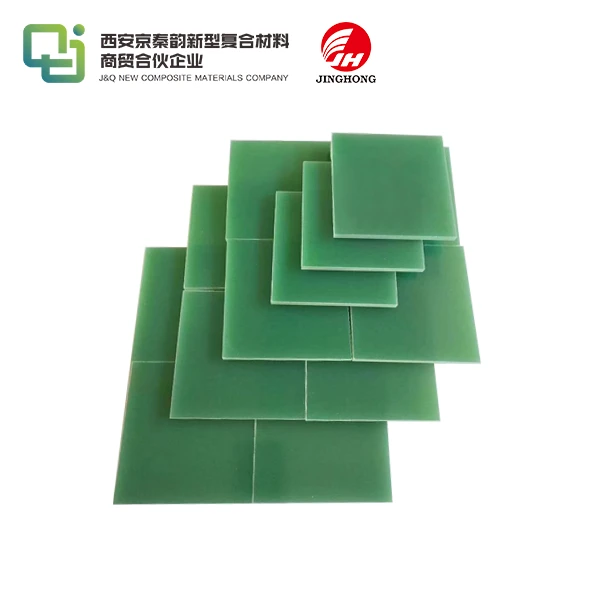

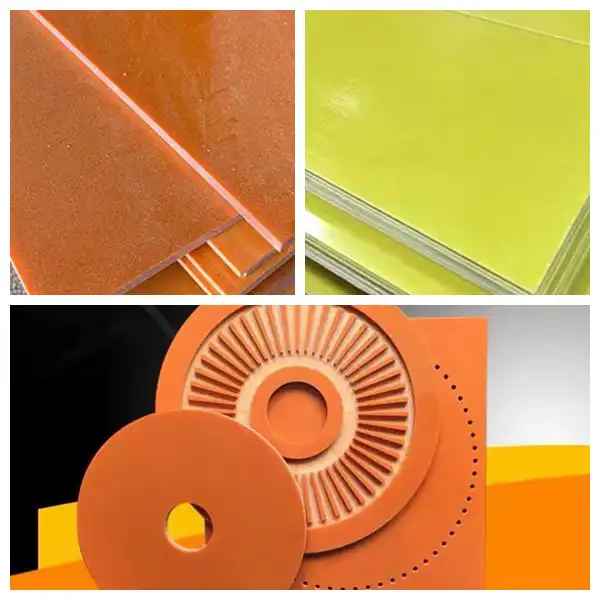

Phenolic paper overlay stands apart for its outstanding toughness, especially in high-temperature conditions, making it imperative across assorted modern applications. This material, made of layers of paper coated with phenolic resin, resists heat well and keeps its structural integrity even after being exposed to high temperatures for a long time.It has excellent mechanical strength, electrical insulation properties, and resistance to chemicals and abrasion as performance characteristics. Because of these characteristics, phenolic paper laminate is ideal for use in electrical insulators, gaskets, bearings, structural components, and electronics, automotive, and aerospace industries.Phenolic paper laminate provides strength and dimensional stability for mechanical components and ensures reliable insulation for electrical applications. Its capacity to withstand heat without deforming or losing any of its properties ensures its durability and operational dependability even under difficult conditions.The cost-effectiveness, ease of fabrication, and adaptability of phenolic paper laminate to meet stringent performance requirements are just a few of the advantages. As a demonstrated material in requesting conditions, its standing for sturdiness supports its broad use across basic modern areas around the world.

What Are the Key Properties of Phenolic Paper Laminate?

Phenolic paper cover is known for its incredible warmth strength and heat resistance. It is made by impregnating layers of paper with phenolic gum. Because it maintains its structural integrity and insulating properties even at high temperatures, this composite material is ideal for demanding applications like electrical insulation and mechanical components.

One of the most important characteristics of the phenolic paper laminate is its high dielectric strength, which ensures its stability under thermal stress. The material will be able to effectively protect electrical components from high temperatures, as a result of this. Furthermore, phenolic overlays are impervious to dampness, improving their sturdiness and life span in different conditions.

How well does Phenolic Paper Overlay act in conditions with high temperatures?

On account of its one of a kind structure, phenolic paper overlay performs well in high-temperature applications. These covers are made of phenolic tar, which has excellent warmth stability and can withstand temperatures up to 135°C (275°F) without deteriorating significantly. It can therefore be utilized in locations where avoiding constant high temperatures is essential.

Adventures like flying, vehicle, and electrical planning oftentimes use phenolic paper overlays for parts that ought to continue on through high warm loads. In the aerospace industry, for instance, these laminates are utilized in aircraft interiors and components that need to be both lightweight and resistant to high temperatures. In a similar vein, automotive under-the-hood applications require phenolic paper laminates to withstand engine heat.

Why Is Phenolic Paper Laminate Ideal for Electrical Insulation?

Phenolic paper laminate is a highly prized material due to its exceptional electrical insulation properties that remain effective even at high temperatures. Due to its high dielectric strength, which effectively prevents electrical arcing and short circuits, this material is required for electrical insulators, components of switchgear, and circuit boards.

In various electrical applications, phenolic paper cover is discernibly used to safeguard essential parts like terminal sheets, breaker arms, and high-voltage switchgear. Electrical frameworks that work under states of high warm pressure benefit from its ability to keep up with dielectric strength and oppose warm debasement.

Furthermore, phenolic covers are leaned toward because of their machinability, which makes it conceivable to definitively shape and manufacture them to meet specific plan prerequisites. They do not produce sparks when struck or machined, which is important when explosive materials are required.

Phenolic paper laminate is suitable for a wide range of industrial applications due to its excellent resistance to chemicals, oils, and moisture in addition to its excellent electrical insulation. Due to its demonstrated track record in maintaining the integrity of electrical components, phenolic paper laminate is a trusted option for applications where reliability and safety are of the utmost importance.

How Does Phenolic Paper Laminate Compare to Other High-Temperature Materials?

When contrasted with different materials appropriate for high-temperature conditions, phenolic paper cover offers particular benefits that highlight its dependability and flexibility. Not at all like specific metals inclined to mellowing or debilitating at raised temperatures, and a few plastics powerless to softening or misshapening, phenolic overlays keep up with their mechanical properties and inflexibility under heat pressure. This consistency guarantees delayed execution and solidness in requesting applications.

The machinability of phenolic overlays further upgrades their allure in modern settings. They can be productively cut, penetrated, and formed with negligible apparatus wear, working with exact assembling processes without compromising underlying respectability. This trademark is vital for creating many-sided parts utilized in electrical protection, switchgear, and other high-temperature applications where careful details are central.

Furthermore, the non-conductive nature of phenolic covers is a huge wellbeing highlight. They don't lead power and don't produce flashes during machining or activity, making them ideal for conditions where combustible gases or materials are available. This intrinsic security profile lessens the gamble of mishaps and guarantees consistence with tough wellbeing principles in different ventures.

In general, the blend of fantastic intensity obstruction, solid mechanical properties, simplicity of machining, and wellbeing benefits positions phenolic paper cover as a favored decision for applications requiring steadiness and execution under outrageous warm circumstances. Its demonstrated history in different modern areas highlights its worth as a reliable material answer for high-temperature conditions.

Conclusion

Phenolic paper laminate stands out as a strong, high-performing material that is suitable for a wide range of high-temperature applications in a variety of industries. It is able to maintain structural integrity and functional dependability even under extreme heat thanks to its exceptional thermal stability. Its consistent performance under thermal stress makes it particularly useful in aerospace and electrical engineering environments, for example.

The material's superior electrical insulation capabilities make it even more useful. Electrical arcing and short circuits are effectively prevented by phenolic paper laminate, enhancing the safety and durability of electrical systems and components. Applications like circuit boards and high-voltage switchgear require uninterrupted electrical insulation, so this dependability is crucial.

Besides, the machinability of phenolic paper cover is a critical benefit in assembling and get together cycles. Without compromising its inherent properties, it is simple to shape, drill, and fabricate to precise specifications. Because machining is so simple, complex parts and components can be made quickly, cheaply, and in accordance with strict industry standards.

In conclusion, phenolic paper laminate is a preferred material for critical applications in challenging environments due to its combination of thermal stability, electrical insulation prowess, and machinability. It is still essential in industries that require dependability, durability, and safety in high-temperature environments due to its proven performance and versatility.

References

1. "Phenolic, Epoxy Countertops - Chemical Resistant Tops | Formaspace." Formaspace. [Read More](https://www.formaspace.com/phenolic-epoxy-countertops)

2. "Norplex-Micarta NP625 - Laminate - Phenolic Compound." Knowde. [Read More](https://www.knowde.com/norplex-micarta-np625)

3. "Norplex-Micarta NP630 - Laminate - Phenolic Compound." Knowde. [Read More](https://www.knowde.com/norplex-micarta-np630)

4. "Custom Laminates and Composites." Franklin Fibre. [Read More](https://www.franklinfibre.com/custom-laminates-composites)