How does a Flame Resistance FR4 Fiber Glass Laminate Sheet perform in harsh weather conditions?

2024-06-13 16:07:08

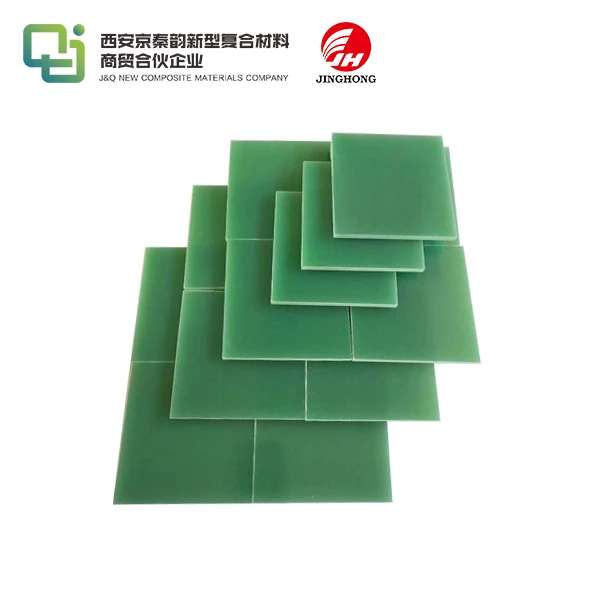

1. Understanding Flame Resistance FR4 Fiber Glass Laminate Sheets

Flame Resistance FR4 Fiber Glass Laminate Sheets are engineered materials known for their exceptional thermal and electrical insulation properties. Composed of woven fiberglass cloth impregnated with an epoxy resin binder, FR4 sheets exhibit high mechanical strength, excellent dimensional stability, and resistance to various environmental factors. Their flame-resistant nature makes them suitable for applications where safety is paramount, such as in electrical equipment and circuit boards.

2. The Composition and Structure of FR4 Fiber Glass Laminate Sheets

The composition of FR4 sheets primarily consists of fiberglass cloth and epoxy resin. The fiberglass cloth provides reinforcement and strength, while the epoxy resin acts as a binder, holding the fibers together and providing resistance to heat and moisture. The manufacturing process involves impregnating the fiberglass cloth with the resin, followed by curing to form a solid laminate. This process ensures uniform distribution of resin throughout the material, resulting in consistent mechanical and electrical properties.

In addition to the basic components, FR4 sheets may also include various additives to enhance specific properties. For instance, flame retardants are often added to improve the material's fire resistance, making it suitable for use in electronic applications where safety is a concern. These additives can be tailored to meet the specific requirements of different applications, providing versatility and adaptability in various industrial contexts.

The structure of Flame Resistance FR4 Fiber Glass Laminate Sheets is meticulously designed to optimize performance. The fiberglass cloth is woven in a specific pattern to maximize strength and durability, while the epoxy resin is formulated to provide optimal bonding and thermal stability. This combination results in a material that is not only strong and durable but also capable of withstanding harsh environmental conditions. The careful control of the manufacturing process ensures that each sheet meets stringent quality standards, making FR4 a reliable choice for a wide range of applications, from printed circuit boards to structural components in high-performance equipment.

3. Thermal Performance in Harsh Weather Conditions

One of the key attributes of Flame Resistance FR4 Fiber Glass Laminate Sheets is their ability to withstand harsh weather conditions, including extreme temperatures. The material exhibits excellent thermal stability, retaining its mechanical and electrical properties over a wide temperature range. Whether exposed to scorching heat or freezing cold, FR4 sheets maintain their structural integrity, making them suitable for outdoor applications where temperature fluctuations are common.

4. Resistance to Moisture and Humidity

In addition to temperature variations, Flame Resistance FR4 Fiber Glass Laminate Sheets demonstrate remarkable resistance to moisture and humidity. The epoxy resin binder effectively seals the fiberglass cloth, preventing water ingress and protecting against delamination. This feature is particularly crucial in environments prone to high humidity levels or occasional exposure to water, such as marine applications or outdoor installations subject to rain and moisture.

The ability of FR4 to withstand moisture and humidity is also important for maintaining its electrical insulation properties. Exposure to moisture can lead to a decrease in the dielectric strength of materials, potentially causing short circuits or other electrical failures. However, the hydrophobic nature of the epoxy resin in FR4 helps to minimize this risk by reducing the absorption of moisture. This characteristic makes FR4 a reliable choice for electrical applications in humid environments or where condensation may occur.

Furthermore, the resistance of FR4 to moisture and humidity contributes to its long-term durability and stability, which are essential for ensuring the reliability of electronic devices over extended periods. In high-humidity conditions, the material's ability to resist moisture uptake prevents swelling and warping, which could otherwise compromise the dimensional stability and performance of the laminate. As a result, FR4 maintains its mechanical integrity and functional properties, ensuring that it can support the electrical components it houses without degrading over time.

In summary, the resistance of FR4 Fiber Glass Laminate Sheets to moisture and humidity is a critical factor in their suitability for various applications, especially in environments where exposure to water or high humidity levels is common. This resistance, combined with the material's thermal and mechanical properties, makes FR4 a versatile and durable choice for a wide range of industries, including electronics, aerospace, and marine sectors.

5. Durability and Longevity in Challenging Environments

FR4 Fiber Glass Laminate Sheets are renowned for their durability and longevity, even in the most demanding environments. The combination of high-strength fiberglass reinforcement and robust epoxy resin matrix ensures that the material can withstand mechanical stress, vibration, and other forms of physical impact. Whether installed in industrial machinery, aerospace components, or telecommunications infrastructure, FR4 sheets deliver reliable performance and extended service life.

Conclusion:

In conclusion, Flame Resistance Flame Resistance FR4 Fiber Glass Laminate Sheets offer exceptional performance in harsh weather conditions, thanks to their unique composition and structural design. With outstanding thermal stability, resistance to moisture, and durability in challenging environments, FR4 sheets are the preferred choice for a wide range of applications where reliability and safety are paramount.

Contact us:

Are you in need of high-quality Flame Resistance FR4 Fiber Glass Laminate Sheets for your next project? Look no further! As a professional manufacturing supplier with a GMP factory and a large inventory, we offer a comprehensive range of FR4 materials to meet your specific requirements. With complete certificates, OEM support, fast delivery, and global buyer cooperation, we are your trusted partner for all your laminate sheet needs. Contact us today at info@jhd-material.com to discuss how we can assist you.

References:

1. "FR-4 (fiberglass)" - Wikipedia

2. "The Basics of FR-4 Substrates" - Sierra Circuits

3. "FR4 Material Properties" - Rush PCB

4. "Introduction to Flame Resistance FR4 Laminate" - Tech-Etch, Inc.

5. "FR-4 Glass Epoxy Laminate" - Multi-CB