How are Epoxy Resin Sheets made?

2024-07-11 17:20:21

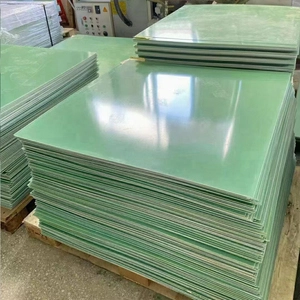

1. Introduction to Epoxy Resin Sheets

Epoxy resins sheets stand as flexible materials with boundless applications across different ventures, including gadgets, aviation, auto, and development. Famous for their extraordinary mechanical properties, synthetic opposition, and strength, these sheets assume a vital part in various basic applications. This article plans to give knowledge into the many-sided course of assembling epoxy resins sheets, explaining the diverse advances engaged with their creation.

Epoxy resins, got from oil based compounds or inexhaustible sources, are mixed with restoring specialists and added substances to accomplish the ideal material attributes. The exact definition of the resins combination is essential in deciding the mechanical strength, warm solidness, and substance obstruction of the subsequent sheets.

2. Raw Materials and Formulation

The assembling system of epoxy resin sheets begins with a fastidious determination of premium-quality natural substances to guarantee the ideal presentation and attributes of the end result. Epoxy resin, got principally from oil based compounds, assume a vital part as the key structure block in the plan of these flexible sheets. These gums are painstakingly mixed with relieving specialists, which can incorporate amines or acids, to catalyze the cross-connecting response answerable for changing the fluid pitch into a strong, solid design. The exact blend and extent of epoxy resin and restoring specialists are vital in deciding the mechanical strength, substance opposition, and warm dependability of the subsequent sheets.

The joining of added substances in the resin combination further improves explicit properties and functionalities of the epoxy gum sheets. Fillers might be acquainted with work on mechanical properties or lessen costs, while plasticizers can improve adaptability and effect obstruction. Shades may likewise be incorporated to give hue or UV obstruction, contingent upon the planned application necessities.

3. Mixing and Dispersion

Upon the careful gathering of unrefined substances, the assembling system of FR4 Epoxy Laminate advances to a basic blending and scattering stage. This urgent step is fundamental for accomplishing consistency and homogeneity in the eventual outcome, guaranteeing that the epoxy tar sheets show predictable execution qualities all through their whole.

The cautious joining of unrefined components, including epoxy tars got from oil, relieving specialists, and added substances, denotes the initiation of the perplexing blending and scattering process. Particular gear, for example, rapid blenders or kneaders is utilized to consistently mix these parts. These high level blending advancements assume a major part in working with the exhaustive and productive combination of the different constituents, laying the foundation for the excellent properties and execution of the subsequent epoxy tar sheets.

During this stage, exact control of boundaries like temperature, tension, and blending time is basic to accomplish ideal outcomes. The administration of these basic factors is fundamental to guarantee exhaustive mixing and scattering of the epoxy gum, relieving specialists, and added substances, eventually adding to the uniform dissemination of material properties inside the epoxy tar sheets.

4. Molding and Curing

When the careful mixing and homogenization of the composite material are effectively finished, the resulting stage includes moving it into molds where the vital relieving process happens. Relieving, a fundamental substance response, is answerable for changing the fluid pitch into a strong state, in this manner granting strength and unbending nature to the material. This groundbreaking system assumes a urgent part in molding the epoxy pitch sheets and guaranteeing that they have the ideal physical and mechanical properties.

The molds used for the arrangement of epoxy resin sheets can change altogether in size and intricacy, custom-made to oblige the particular ascribes and necessities of the eventual outcome. Whether delivering a straightforward level sheet or an unpredictably formed part, the molds assume a basic part in characterizing a definitive construction and qualities of the epoxy gum sheets.

During the restoring system, the resin goes through a sub-atomic change, progressing from a moldable state to a solidified structure. This stage is painstakingly controlled to improve the material's properties, including its hardness, versatility, and warm soundness. The exact circumstances and length of the restoring system are carefully figured out how to guarantee consistency and consistency across the whole surface of the sheets, in this manner ensuring the achievement of the expected physical and mechanical characteristics.

The most common way of trim epoxy resin sheets involves the controlled restoring of the material inside particular molds, at last forming the physical and mechanical properties of the finished result. Through cautious administration of the restoring system and the use of custom molds, makers can guarantee the reliable creation of epoxy pitch sheets with the ideal credits, taking care of an extensive variety of modern and designing prerequisites.

5. Quality Control and Testing

Quality control is a critical aspect of the manufacturing process to ensure that the epoxy resin sheets meet stringent standards for performance and reliability. Throughout production, samples are periodically taken and subjected to various tests such as dimensional analysis, mechanical testing, and thermal analysis. These tests help identify any defects or inconsistencies and allow for adjustments to be made to the manufacturing process if necessary. Additionally, the finished sheets undergo comprehensive quality inspection before being released for distribution.

In conclusion, the production of FR4 Epoxy Laminate is a complex yet meticulously controlled process that involves precise formulation, mixing, molding, curing, and quality testing. By adhering to strict quality standards and leveraging advanced manufacturing techniques, manufacturers can produce the resin sheets that meet the diverse needs of industries worldwide.

Contact us

Are you in need of high-quality epoxy resin sheets for your industrial applications? Look no further! As a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates, we are committed to providing you with top-notch products and exceptional service. Whether you require OEM support, fast delivery, or comprehensive testing capabilities, we have you covered. Contact us today at info@jhd-material.com to discuss your requirements and explore how we can collaborate to meet your needs.

References

- "Epoxy Resins: Chemistry and Technology" by Clayton May, Wiley, 1988.

- "Handbook of Epoxy Resins" edited by Lee H. Lee, McGraw-Hill, 1967.

- "Epoxy Resins: Advanced Materials and Applications" edited by Jean-Pierre Pascault and Roberto J. J. Williams, Wiley, 2010.

- "Epoxy Adhesive Formulations" by Edward M. Petrie, William Andrew, 2005.

- "Epoxy Resins and Composites I" edited by Sabu Thomas, Raghavan B. Sunoj, and Kochumalayil J. Abraham, Springer, 2010.