HDPE vs. Delrin: A Comprehensive Comparative Analysis

2024-12-10 17:17:13

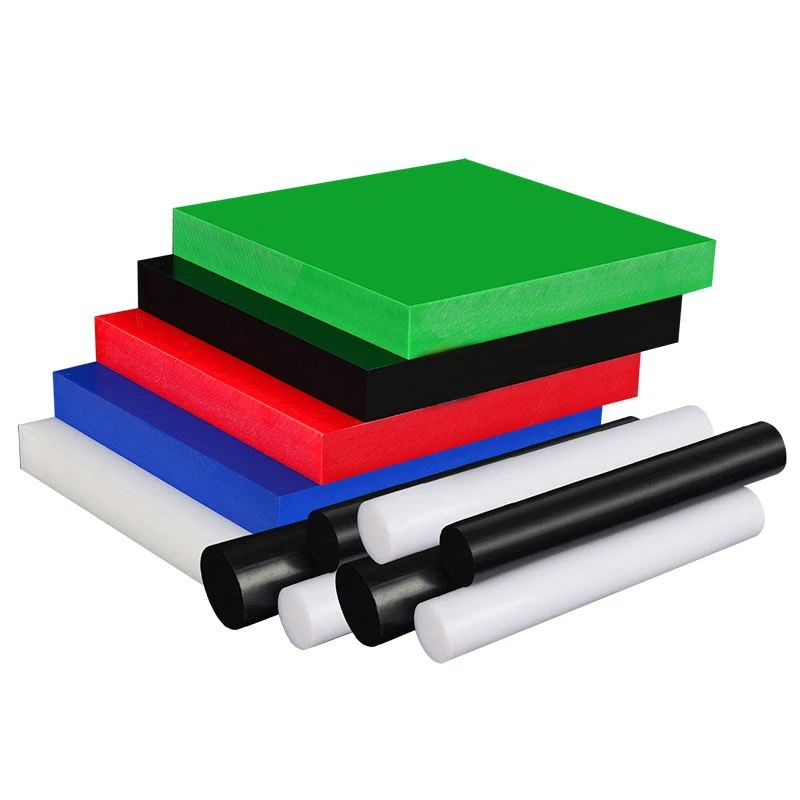

In the world of engineering plastics, two materials stand out for their exceptional properties and versatile applications: High-Density Polyethylene (HDPE) and Delrin, also known as Polyoxymethylene (POM). As a manufacturer with over two decades of experience in producing and selling insulating sheets, we've witnessed the growing importance of these materials across various industries. This comprehensive analysis aims to shed light on the characteristics, advantages, and applications of HDPE and Delrin, helping you make informed decisions for your projects.

Material Properties and Characteristics

Chemical Composition and Structure

HDPE is a polyethylene thermoplastic made from petroleum. It's composed of long chains of ethylene molecules, resulting in a high degree of linearity and crystallinity. This structure gives HDPE its characteristic strength and density.

Delrin, on the other hand, is an engineering thermoplastic produced from formaldehyde. Its molecular structure consists of alternating methylene and oxygen atoms, forming a highly crystalline polymer with excellent mechanical properties.

Mechanical Properties

HDPE boasts remarkable impact resistance, tensile strength, and flexibility. It's known for its ability to withstand high loads without deforming permanently. HDPE's low coefficient of friction makes it ideal for applications requiring smooth movement.

Delrin exhibits superior stiffness, dimensional stability, and fatigue resistance. It maintains its mechanical properties over a wide temperature range and offers excellent creep resistance. Delrin's low moisture absorption contributes to its stability in various environments.

Thermal Properties

HDPE has a relatively low melting point compared to other engineering plastics, typically around 130°C to 137°C. It maintains its properties well at low temperatures, making it suitable for cryogenic applications.

Delrin has a higher melting point, approximately 175°C, allowing it to withstand higher temperatures. It retains its mechanical strength and dimensional stability across a broader temperature range than HDPE.

Performance Comparison

Wear Resistance and Durability

HDPE is well-regarded for its outstanding abrasion resistance and durability, making it ideal for applications where sliding or impact is common. Its self-lubricating nature further enhances its performance in dynamic environments, ensuring extended service life.

On the other hand, Delrin surpasses HDPE in wear resistance, particularly under conditions of continuous friction. Its superior fatigue resistance and excellent dimensional stability make Delrin the material of choice for precision components exposed to repeated stress, ensuring long-term reliability and high performance.

Chemical Resistance

HDPE is known for its exceptional chemical resistance, able to withstand a broad spectrum of acids, bases, and organic solvents. This makes it highly reliable for use in chemical processing, storage tanks, and pipes, where durability against corrosive substances is essential.

Delrin, while offering good resistance to many chemicals, can be susceptible to damage from strong acids and oxidizing agents. However, its resilience in fuel and hydrocarbon environments makes it a top choice for automotive and engine components, where reliability under harsh conditions is crucial.

Electrical Properties

HDPE is a superior electrical insulator, offering high dielectric strength and low electrical conductivity, which makes it an ideal material for electrical wiring, cables, and telecommunications equipment. Its ability to resist electrical current ensures safety and efficiency in these industries.

Delrin, while not as strong an insulator as HDPE, still provides reliable electrical properties. Its exceptional dimensional stability and precision make it perfect for applications in electrical components where tight tolerances and durability are essential, such as connectors and switches.

Applications and Industry Usage

Industrial Applications

HDPE is widely used in industries where chemical resistance and durability are crucial. It is commonly found in the production of pipes, tanks, and containers, as well as geomembranes used in environmental protection. Its versatility also extends to durable consumer goods, making it a go-to material for applications requiring long-lasting performance.

In contrast, Delrin is favored for precision engineering, particularly in gears, bearings, and bushings. Its excellent dimensional stability and low friction properties make it ideal for high-performance automotive components, consumer electronics, and industrial machinery.

Medical and Food Industry Applications

HDPE's non-toxic properties and chemical inertness make it an ideal material for food packaging, ensuring safety and long shelf life. It's also widely used in medical applications, including prosthetics and orthopedic implants, thanks to its excellent biocompatibility.

Delrin, available in high-purity grades, is approved for use in food processing equipment and specific medical devices. Its ability to withstand repeated sterilization processes enhances its value in reusable medical instruments, providing durability and reliability in critical healthcare applications.

Specialized and Emerging Applications

HDPE is increasingly used in sustainable applications, such as recyclable packaging and eco-friendly construction materials. Its lightweight nature and durability make it a preferred material in the aerospace and marine industries.

Delrin is finding new applications in 3D printing and additive manufacturing due to its excellent machinability and dimensional stability. It's also being explored for use in advanced robotics and automation systems.

Conclusion

Both HDPE and Delrin offer unique advantages in various applications. HDPE excels in chemical resistance, impact strength, and electrical insulation, making it ideal for large-scale industrial and environmental applications. Delrin shines in precision engineering, offering superior wear resistance and dimensional stability crucial for high-performance mechanical components. The choice between these materials ultimately depends on the specific requirements of your project, considering factors such as operating conditions, precision needs, and environmental exposure.

Contact Us

For expert guidance on selecting the right material for your application or to learn more about our range of insulating sheets, don't hesitate to reach out. Contact us at info@jhd-material.com, and let our 20+ years of experience work for you.

References

1. Peacock, A. J. (2000). Handbook of Polyethylene: Structures: Properties, and Applications. Marcel Dekker, Inc.

2. Brydson, J. A. (1999). Plastics Materials. Butterworth-Heinemann.

3. Mascia, L. (2012). Thermoplastics: Materials Engineering. Springer Science & Business Media.

4. Kurtz, S. M. (2015). UHMWPE Biomaterials Handbook: Ultra High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices. William Andrew.

5. Saechtling, H., & Woebcken, W. (1995). International Plastics Handbook: For the Technologist, Engineer and User. Hanser Publishers.

6. Rosato, D. V., Rosato, M. G., & Rosato, D. V. (2000). Concise Encyclopedia of Plastics. Springer Science & Business Media.

_1740986340093.webp)