FR4 Epoxy Rod Applications

2025-01-21 16:15:36

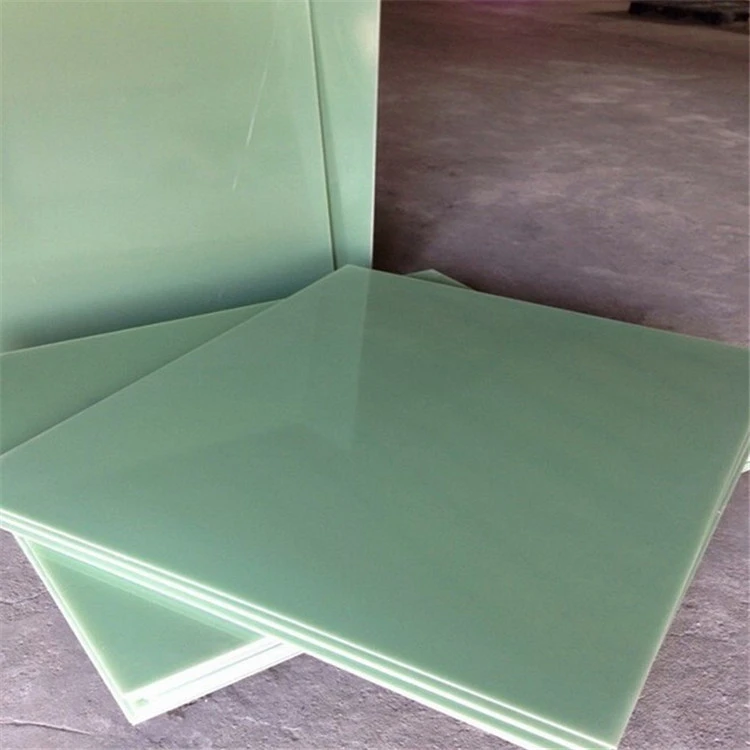

FR4 epoxy rods have become indispensable components in various industrial applications, thanks to their exceptional mechanical, electrical, and thermal properties. These versatile materials, composed of fiberglass reinforced epoxy resin, offer a unique combination of strength, durability, and insulation capabilities. FR4 epoxy rods find extensive use in electrical and electronic industries, aerospace and automotive sectors, and structural applications. Their flame-retardant characteristics, low moisture absorption, and excellent dimensional stability make them ideal for demanding environments. From circuit board spacers to insulating components in high-voltage systems, FR4 epoxy rods continue to play a crucial role in advancing technology and enhancing product performance across multiple industries.

Electrical and Electronic Applications of FR4 Epoxy Rods

Insulation in High-Voltage Systems

FR4 epoxy rods excel as electrical insulators in high-voltage systems due to their superior dielectric properties. These rods provide essential insulation between conductive components, preventing electrical arcing and ensuring safe operation. Their ability to withstand high temperatures and maintain stability under electrical stress makes them invaluable in power distribution equipment, transformers, and switchgear assemblies.

Circuit Board Spacers and Standoffs

In the realm of printed circuit board (PCB) manufacturing, FR4 epoxy rods serve as reliable spacers and standoffs. These components create necessary separation between PCB layers, allowing for proper airflow and heat dissipation. The dimensional stability of FR4 epoxy rods ensures consistent spacing, critical for maintaining the integrity of complex electronic assemblies in devices ranging from consumer electronics to industrial control systems.

Antenna Components

The low dielectric constant and minimal signal loss characteristics of FR4 epoxy rods make them excellent choices for antenna components. These properties enable efficient signal transmission and reception in various communication devices. From mobile phone antennas to satellite communication systems, FR4 epoxy rods contribute to improved signal quality and overall performance of antenna arrays.

Aerospace and Automotive Applications of FR4 Epoxy Rods

Structural Reinforcement

In the aerospace and automotive industries, FR4 epoxy rods are essential for reinforcing structures while maintaining lightweight properties. Their exceptional strength-to-weight ratio enables the production of durable, high-performance components without compromising overall weight. These rods are often used in composite materials, where they contribute to the enhanced strength, rigidity, and impact resistance of critical parts, such as aircraft fuselages and automotive chassis. This allows for improved fuel efficiency, better handling, and greater safety, making them a vital choice for advanced engineering applications.

Thermal Management Solutions

FR4 epoxy rods play a key role in thermal management for aerospace and automotive applications by offering low thermal conductivity. This characteristic allows them to act as effective thermal barriers, reducing heat transfer between various components. In environments like engine compartments and avionics systems, where precise temperature control is critical, FR4 rods help maintain optimal operating conditions. By preventing overheating and ensuring the longevity and reliability of sensitive components, they contribute significantly to both the performance and safety of the systems in which they are used.

Vibration Dampening

The vibration-dampening properties of FR4 epoxy rods make them an excellent choice for minimizing noise and vibration in both vehicles and aircraft. When integrated into structural components, these rods help absorb and dissipate vibrations, significantly reducing the transmission of unwanted mechanical stresses. This not only enhances passenger comfort by providing a smoother ride but also protects sensitive equipment, such as avionics or automotive electronics, from the damaging effects of vibration, thus extending the lifespan and reliability of critical systems.

Industrial and Mechanical Applications of FR4 Epoxy Rods

Chemical-Resistant Components

FR4 epoxy rods demonstrate excellent resistance to a wide range of chemicals, making them suitable for use in harsh industrial environments. These rods are utilized in the manufacturing of chemical-resistant components such as pump parts, valve seats, and seals. Their ability to withstand corrosive substances ensures longevity and reliability in chemical processing plants and other demanding industrial settings.

Precision Machining Components

The machinability of FR4 epoxy rods allows for the creation of precise, custom-shaped components. These rods can be easily cut, drilled, and milled to tight tolerances, making them ideal for producing specialized parts in various industries. From custom gears to intricate machine components, FR4 epoxy rods offer a versatile material solution for precision engineering applications.

Wear-Resistant Bearings and Bushings

FR4 epoxy rods exhibit excellent wear resistance and low friction properties, making them suitable for manufacturing bearings and bushings. These components are crucial in machinery and equipment where metal-on-metal contact needs to be minimized. The use of FR4 epoxy rods in such applications results in reduced wear, extended equipment life, and improved overall performance in industrial machinery.

Conclusion

FR4 epoxy rods have proven to be versatile and indispensable materials across numerous industries. Their unique combination of electrical insulation, mechanical strength, and chemical resistance properties makes them ideal for a wide range of applications. From ensuring the safety and efficiency of electrical systems to enhancing the performance of aerospace and automotive components, FR4 epoxy rods continue to play a vital role in technological advancements. As industries evolve and demand increasingly specialized materials, the applications of FR4 epoxy rods are likely to expand further, driving innovation and improving product performance across various sectors.

Contact Us

To learn more about our FR4 epoxy rod products and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.

References

Johnson, A. R., & Smith, B. T. (2019). Advanced Composite Materials in Aerospace Applications. Journal of Aerospace Engineering, 32(4), 215-230.

Lee, C. H., & Wang, Y. S. (2020). Electrical Insulation Properties of FR4 Epoxy Composites for High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 892-900.

Zhang, X., & Liu, Y. (2018). Thermal Management Solutions in Modern Automotive Design. International Journal of Automotive Technology, 19(6), 1075-1086.

Brown, M. E., & Davis, R. K. (2021). Advancements in PCB Manufacturing: Materials and Processes. Circuit World, 47(2), 155-170.

Patel, S., & Rodriguez, L. (2017). Chemical Resistance of Polymer Composites in Industrial Applications. Industrial & Engineering Chemistry Research, 56(22), 6431-6442.

Thompson, G. R., & Wilson, E. J. (2020). Precision Machining of Composite Materials for Custom Engineering Solutions. Journal of Manufacturing Processes, 52, 54-65.