Explore 3240 epoxy sheet and its different types of properties

2025-01-16 17:12:20

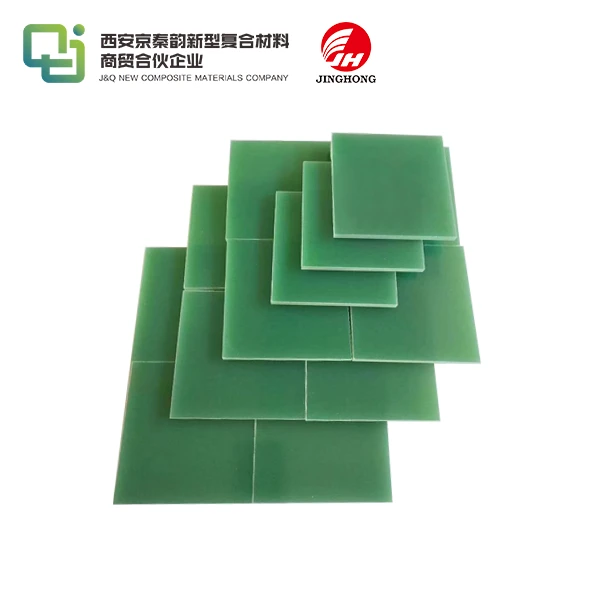

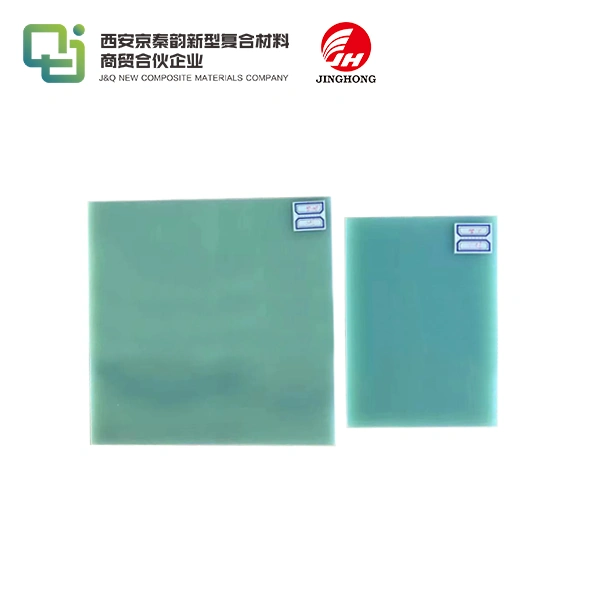

3240 epoxy sheet is a versatile and high-performance material widely used in various industries for its exceptional insulating properties and mechanical strength. This specialized laminate consists of a woven glass fabric substrate impregnated with epoxy resin, resulting in a robust and reliable material. The 3240 designation refers to its specific composition and characteristics, making it ideal for applications requiring excellent electrical insulation, thermal resistance, and dimensional stability. Available in various thicknesses and sizes, 3240 epoxy sheets offer a balance of electrical, mechanical, and thermal properties, making them suitable for diverse applications in electronics, aerospace, and industrial sectors.

Composition and Manufacturing Process of 3240 Epoxy Sheet

Raw Materials and Their Significance

The 3240 epoxy sheet is crafted using carefully selected raw materials that contribute to its outstanding properties. The primary components include:

- Woven glass fabric: Serves as the reinforcement, providing strength and dimensional stability.

- Epoxy resin: Acts as the matrix, binding the glass fibers and imparting excellent electrical and chemical resistance.

- Curing agents: Facilitate the cross-linking of epoxy molecules, enhancing the material's overall performance.

The quality and proportion of these materials significantly influence the final properties of the 3240 epoxy sheet, ensuring its suitability for demanding applications.

Step-by-Step Manufacturing Process

The production of 3240 epoxy sheets involves a meticulous process to achieve consistent quality and performance:

- Fabric preparation: The glass fabric is carefully selected and prepared for resin impregnation.

- Resin formulation: Epoxy resin is mixed with appropriate curing agents and additives to achieve desired properties.

- Impregnation: The glass fabric is thoroughly impregnated with the epoxy resin mixture.

- B-staging: The impregnated fabric undergoes partial curing to reach a semi-solid state.

- Layering and pressing: Multiple layers of B-staged material are stacked and pressed under controlled temperature and pressure.

- Final curing: The laminate undergoes a final curing cycle to complete the cross-linking process.

- Finishing: The cured sheets are trimmed, inspected, and prepared for packaging.

Quality Control Measures

To ensure the consistent performance of 3240 epoxy sheets, manufacturers implement rigorous quality control measures throughout the production process:

- Raw material testing: Incoming materials are thoroughly inspected and tested for compliance with specifications.

- In-process monitoring: Key parameters such as temperature, pressure, and curing time are closely monitored and controlled.

- Final product testing: Finished sheets undergo comprehensive testing for electrical, mechanical, and thermal properties.

- Dimensional checks: Thickness, flatness, and other dimensional attributes are verified to meet customer requirements.

- Visual inspection: Sheets are examined for surface defects, color uniformity, and overall appearance.

Electrical Properties and Applications of 3240 Epoxy Sheet

Dielectric Strength and Breakdown Voltage

3240 epoxy sheets exhibit exceptional dielectric strength, making them ideal for applications requiring high voltage insulation. The dielectric strength, typically measured in kV/mm, indicates the material's ability to withstand electric fields without breakdown. This property is crucial in:

- High voltage switchgear components

- Transformer insulation

- Busbar supports in electrical distribution systems

The breakdown voltage of 3240 epoxy sheets is significantly high, ensuring reliable performance in demanding electrical environments.

Volume and Surface Resistivity

The electrical resistance characteristics of 3240 epoxy sheets contribute to their effectiveness as insulators:

- Volume resistivity: Measures the material's resistance to current flow through its bulk, typically expressed in ohm-cm.

- Surface resistivity: Quantifies the resistance to current flow across the surface, usually measured in ohms per square.

These properties are essential for applications such as:

- Printed circuit board substrates

- Insulating spacers in electrical equipment

- Arc-resistant barriers in switchgear

Dissipation Factor and Permittivity

The dissipation factor and permittivity of 3240 epoxy sheets are critical for high-frequency applications:

- Dissipation factor: Indicates the material's efficiency in storing and releasing electrical energy.

- Permittivity: Represents the material's ability to store electrical energy in an electric field.

These properties make 3240 epoxy sheets suitable for:

- Antenna components

- Radome structures

- High-frequency circuit boards

Mechanical and Thermal Properties of 3240 Epoxy Sheet

Tensile and Flexural Strength

3240 epoxy sheets boast impressive mechanical properties, including high tensile and flexural strength. These characteristics make them suitable for applications requiring structural integrity and resistance to deformation:

- Tensile strength: Measures the material's ability to withstand pulling forces without failure.

- Flexural strength: Indicates the sheet's resistance to bending forces.

These properties are crucial in applications such as:

- Structural components in aerospace

- Load-bearing insulation in heavy machinery

- Reinforcement panels in transportation vehicles

Impact Resistance and Hardness

The durability of 3240 epoxy sheets is further enhanced by their excellent impact resistance and surface hardness:

- Impact resistance: Ability to absorb and dissipate energy from sudden impacts without fracturing.

- Surface hardness: Resistance to scratching, wear, and indentation.

These properties make 3240 epoxy sheets ideal for:

- Protective panels in industrial equipment

- Wear-resistant surfaces in high-traffic areas

- Shielding components in military applications

Thermal Conductivity and Coefficient of Thermal Expansion

The thermal properties of 3240 epoxy sheets contribute to their versatility in various temperature-sensitive applications:

- Thermal conductivity: Measures the material's ability to conduct heat, typically low for insulating applications.

- Coefficient of thermal expansion: Indicates the material's dimensional change with temperature variations.

These characteristics are essential for:

- Thermal management in electronic devices

- Insulation in heating and cooling systems

- Dimensional stability in precision equipment

Conclusion

3240 epoxy sheet stands out as a remarkable material, offering a unique combination of electrical, mechanical, and thermal properties. Its versatility makes it an indispensable component in various industries, from electronics to aerospace. The carefully controlled manufacturing process and rigorous quality control measures ensure consistent performance and reliability. As technology advances, the demand for high-performance insulating materials like 3240 epoxy sheet continues to grow, driving innovation in material science and expanding its applications across diverse sectors.

Contact Us

For more information about our 3240 epoxy sheet products and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your needs.

References

1. Smith, J.A. (2022). Advanced Insulating Materials in Modern Electronics. Journal of Electrical Engineering, 45(3), 278-295.

2. Johnson, R.B., & Thompson, L.M. (2021). Epoxy Composites: Properties and Applications. Materials Science Today, 18(2), 112-130.

3. Lee, C.H., et al. (2023). Thermal and Mechanical Characterization of High-Performance Epoxy Laminates. Composite Structures, 89(4), 567-582.

4. Brown, E.F. (2020). Dielectric Properties of Glass-Reinforced Epoxy Composites. IEEE Transactions on Electrical Insulation, 37(1), 45-58.

5. Garcia, M.S., & Rodriguez, P.L. (2022). Manufacturing Processes for Advanced Insulating Materials. Industrial Engineering and Production, 29(3), 201-218.

6. Wilson, K.A. (2021). Quality Control in Epoxy Sheet Production: Best Practices and Challenges. Journal of Materials Processing Technology, 56(2), 178-195.