Phenolic Sheet 4x8

Basic Information:

Brand: JingHong

Type: phenolic cotton board & phenolic paper board

Thickness: 0.5mm --- 100mm

Regular Size: 1020mm*2020mm

Packaging: Regular packing, Protect by Pallet

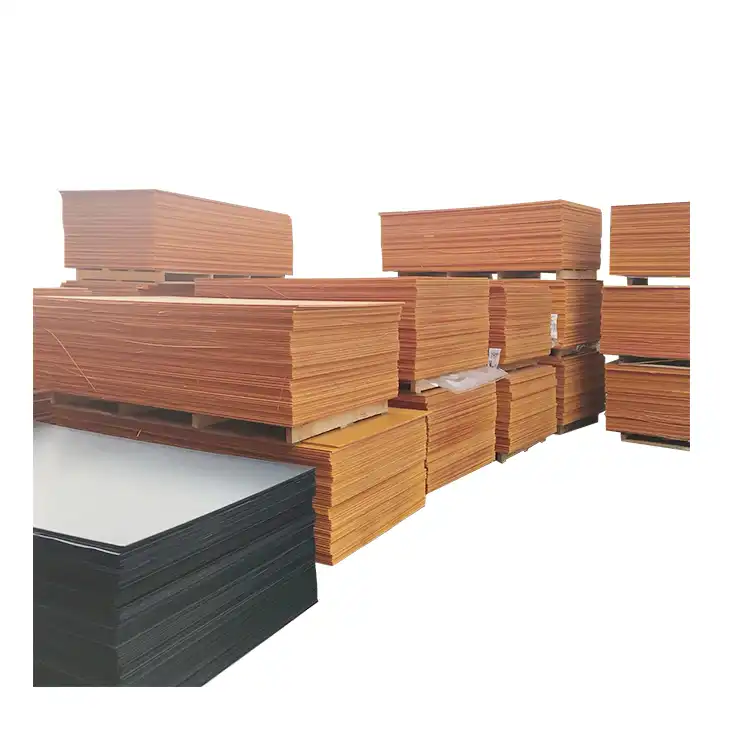

Productivity: 13000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

Phenolic cotton laminate definition and use

Phenolic Sheet is made of cotton cloth impregnated with phenolic resin by drying and hot pressing, 3026 is made of bleached cloth impregnated with phenolic resin by hot pressing and laminates. 3025 has high mechanical properties, suitable for machinery, motors, electrical equipment for insulating structural parts, and can be used in transformer oil. 3026 has high mechanical strength, suitable for tape gear wheel, guide wheels and other mechanical products.

Technical Requirements

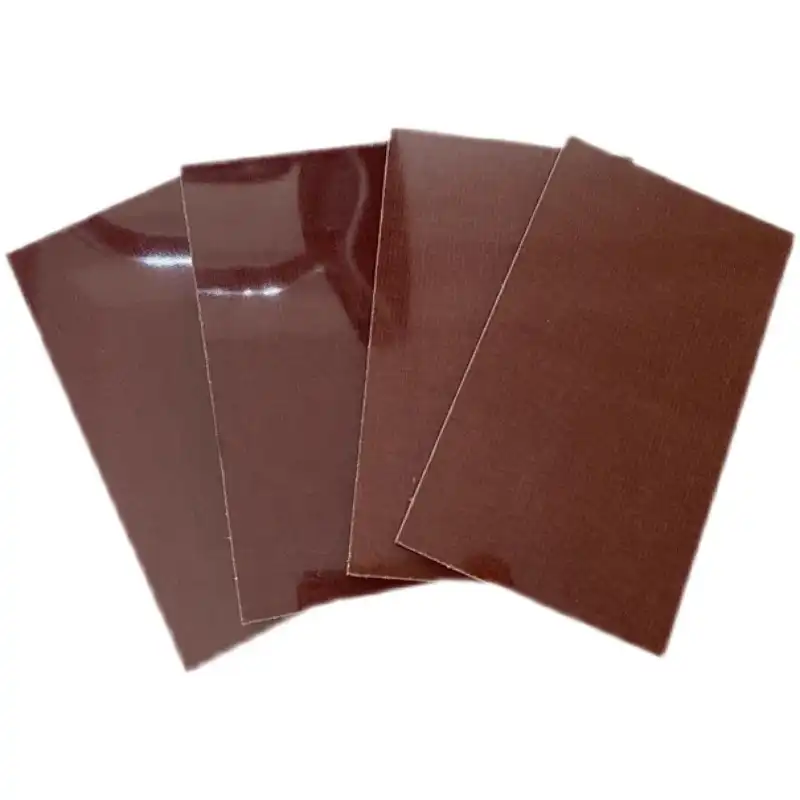

Phenolic cotton laminate appearance

The surface of phenolic cotton laminate should be flat, no vapor bubbles, pockmarks and impurities, a small number of spots are allowed. The edge should be neatly cut, and the end face should not have delamination and cracks.

Application

Phenolic Cotton Cloth Laminated Sheet is suitable for base of MV panel, processing parts of insulating materials, pads for drilling in the PCB industry, distribution boxes, jig boards, mold splints, high and low voltage wiring boxes. Also, it is used in bearings and gears of motors, mechanical molds, ICT jigs, forming machines, drilling machines, Table top grinding pads, packaging machine, etc.

It can be machined to bakelite tea tray board

3021 Phenolic Paper Board

3021 Phenolic Paper Laminate Sheet is made of insulation paper impregnated with phenolic resin in heat-rolling and tightening, baking and curing. Widely used as insulating structure parts in motor, electrical equipment and used in transformer oil. Suitable for being the backup board for PCB, switch cabinet, jag board, die splint, packing machine, high frequency welding machine, forming machine, drilling machine and table grinding machine, etc.

Black and orange phenolic paper boards are both available now! There are two sizes which are 1040mm * 2080mm and 1220mm * 2440mm.

|

|

|

Table 1:Performance index of phenolic cotton cloth laminate

|

Serial No. |

Project name |

Unit |

Test method |

Targets |

||

| 3025 | 3026 | |||||

|

1 |

Density |

g/cm |

GB/T5130 |

1.30~1.40 |

- |

|

|

2 |

Absorbent |

mg |

GB/T5130 |

Refer to table 2 | Refer to table 3 | |

|

3 |

Vertical Layer Bending Strength Longitudinal |

Mpa |

GB/T5130 (Q/JBQP51-2001) |

≥100 |

≥140 |

|

|

4 |

Tensile Strengths |

Mpa |

GB/T5130中 |

≥(80) |

≥98 |

|

|

5 |

bonding strength |

N |

JB886-75 |

≥(5390) |

||

|

6 |

Compression strength Vertical Layer Parallel Layer |

MPa |

GB/T5130 |

- - |

≥245 ≥147 |

|

|

7 |

Notched impact strength (simply supported beams) Parallel Layer |

kJ/m |

GB/T5130 |

≥8.8 |

≥6.8 |

|

|

8 |

Parallel layerwise insulation resistance After immersion in water |

Ω |

GB/T5130 |

≥1.0×10 |

- |

|

|

9 |

Parallel layer breakdown voltage In transformer oil at (90+2)°C |

kV |

GB/T5130 |

≥10 |

- |

|

|

10 |

Vertical laminar electrical strength In transformer oil at (90+2)°C |

kV/mm |

GB/T5130 |

Refer to Table4 |

- |

|

Table 2:Water absorption of phenolic cotton cloth laminate

|

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) | absorbency(mg) | Average thickness(mm) | absorbency(mg) |

|

0.8 |

≤201 |

3.0 |

≤249 |

12.0 |

≤336 |

|

1.0 |

≤206 |

4.0 |

≤262 |

14.0 |

≤354 |

|

1.2 |

≤211 |

5.0 |

≤275 |

16.0 |

≤371 |

|

1.6 |

≤220 |

6.0 |

≤284 |

20.0 |

≤406 |

|

2.0 |

≤229 |

8.0 |

≤301 |

25.0 |

≤450 |

|

2.5 |

≤239 |

10.0 |

≤319 |

One-sided processing to 22.5 |

≤540 |

Table 3:Water absorption of phenolic cotton cloth laminate

| Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

|

0.4 |

≤186 |

2.0 |

≤229 |

10 |

≤319 |

|

0.5 |

≤190 |

2.5 |

≤239 |

12 |

≤336 |

|

0.6 |

≤194 |

3.0 |

≤249 |

14 |

≤354 |

|

0.8 |

≤201 |

4.0 |

≤262 |

16 |

≤371 |

|

1.0 |

≤206 |

5.0 |

≤275 |

20 |

≤406 |

|

1.2 |

≤211 |

6.0 |

≤284 |

25 |

≤450 |

|

1.6 |

≤220 |

8.0 |

≤301 |

One-sided processing to 22.5 |

≤540 |

Table 4:Electrical strength of phenolic cotton fabric laminates

| Average thickness(mm) |

Electrical Strength(kV/mm) |

Average thickness(mm) | Electrical Strength(kV/mm) | Average thickness(mm) | Electrical Strength(kV/mm) |

|

0.8 |

≥0.89 |

1.6 |

≥0.72 |

2.6 |

≥0.56 |

|

0.9 |

≥0.84 |

1.8 |

≥0.69 |

2.8 |

≥0.53 |

|

1.0 |

≥0.82 |

2.0 |

≥0.65 |

3.0 |

≥0.50 |

|

1.2 |

≥0.80 |

2.2 |

≥0.61 |

||

|

1.4 |

≥0.76 |

2.4 |

≥0.58 |

Factory

Hongda Insulation Materials Factory is a new material enterprise integrating scientific research, development, production, sales and service. The company has expanded its scale constantly through years of accumulated development, and the main products include 3240 epoxy plate, FR4 fiberglass sheet, 3026 phenolic cotton board, and phenolic paper board.

Our company covers an area of 30,000m2, with 13,000 tons of annual productivity, more than 20 full-time, and part-time senior engineering technicians and new product developers as well as stronger development and production capacity of insulating plate products.

Our company is also the partner of foreign merchants and foreign trade enterprises. There are lots of trading company from both China and other countries taking the products from us each year.

One of our greatest advantage is the orders which are directly from us has the priority to produce first. Also, we have our own logistics company, so it can provide safe and fast service to you. What we are trying to do is providing our customers one-stop service from production to delivery.

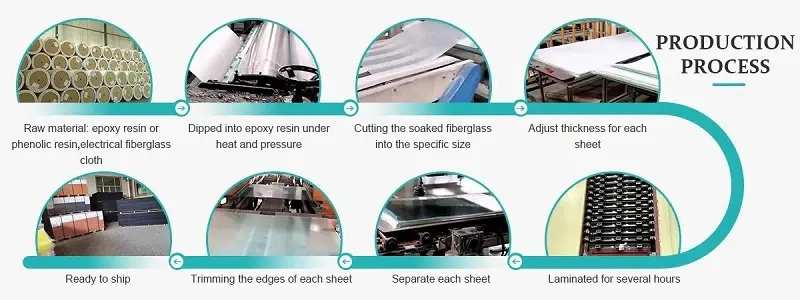

Production Process

|

|

Packaging and Shipping

Regular packing, Protect by Pallet

Send Inquiry