Does casting resin break easily?

2024-09-11 17:06:06

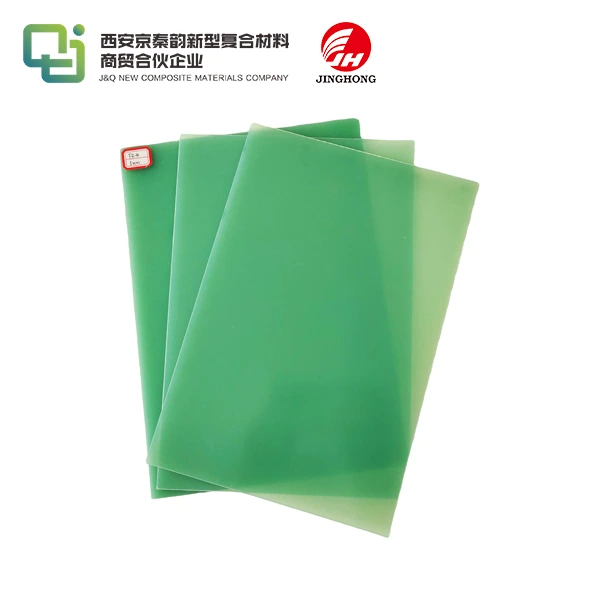

Due to its versatility and unique properties, casting resin has gained popularity in a variety of artistic and business contexts. In any case, a typical inquiry that emerges among clients and potential purchasers is: does casting resin break without any problem? This comprehensive guide will discuss casting resin's durability, the factors that influence its strength, and ways to improve its resilience.

Understanding Casting Resin's Durability

Casting resin is known for being strong, but how long it lasts can vary depending on a number of factors. How about we investigate the innate attributes that add to its solidarity and likely weaknesses.

Substance Creation and Its Effect on Strength

The substance cosmetics of casting resin assumes an essential part in deciding its solidness. The majority of casting resins are based on epoxy or polyurethane, which have distinct properties. Epoxy pitches by and large give unrivaled hardness and synthetic obstruction, while polyurethane tars offer upgraded adaptability and effect opposition.

Hardness versus Adaptability: Tracking down the Right Equilibrium

The hardness of casting resin is many times estimated on the Shore D scale. Even though a material's Shore D value is higher, this does not necessarily mean that it is more durable overall. Unreasonably hard saps might be weak and inclined to breaking under influence, while additional adaptable tars can ingest stuns better yet might be more defenseless to scratches or misshapenings.

Resin Integrity and the Environment

Environmental conditions can have a significant impact on the longevity and durability of casting resin. Openness to UV radiation, outrageous temperatures, and high stickiness can prompt corruption over the long haul. While some resins contain UV stabilizers to prevent sun damage, others may necessitate additional outdoor protection.

Factors Influencing Casting Resin's Breakability

A few factors can influence the probability of casting resin breaking. Understanding these variables is urgent for the two makers and end-clients to guarantee ideal execution and life span of gum based items.

Relieving Cycle and Its Impact on Strength

The relieving system is significant in deciding the last strength of casting resin. A weaker final product may result from improper curing, which can be caused by inadequate temperature control, improper mixing ratios, or insufficient curing time. Appropriate relieving guarantees the pitch arrives at its most extreme strength and toughness potential.

Thickness and Resin Resilience

The breakability of a casting resin application is significantly influenced by its thickness. Under stress, thinner layers are typically more likely to crack or break. On the other hand, thicker applications appropriate powers all the more equally, improving by and large strength. Notwithstanding, exorbitantly thick pours may prompt overheating during relieving, possibly compromising the tar's respectability.

Added substances and Fillers

Different added substances and fillers can be integrated into casting resin to upgrade its sturdiness. Fiberglass or casting resin fortifications can emphatically increment rigidity and effect opposition. Silica fillers can further develop hardness and scraped area opposition, while flexibilizers can improve the sap's capacity to endure influence without breaking.

Techniques to Prevent Casting Resin from Breaking

While casting resin is intrinsically strong, certain strategies can be utilized to additionally diminish the gamble of breakage and expand the life expectancy of sap based items.

Proper Mixing and Applying Techniques

It is essential to adhere to the manufacturer's recommendations for mixing ratios and applying techniques. Appropriate blending guarantees uniform relieving and ideal strength improvement. Procedures, for example, degassing can wipe out air bubbles that might debilitate the end result. Additionally, issues related to heat buildup during curing can be avoided by applying resin in thin, multiple layers rather than in a single, thick pour.

Strategies for Reinforcement to Increase Strength

Casting resin projects' strength and durability can be significantly improved by incorporating reinforcement materials. A composite structure with a superior strength-to-weight ratio can be created by layering fiberglass cloth or mat inside the resin. The embedding of natural fibers or even wire mesh can provide additional reinforcement for smaller items without significantly altering their appearance.

Surface Readiness and Completing Procedures

Legitimate surface planning prior to applying casting resin can significantly further develop attachment and decrease the gamble of delamination or breaking. Sanding, degreasing, and utilizing fitting preliminaries can improve the connection between the pitch and the substrate. Subsequent to relieving, applying a defensive clear coat or sealant can give an extra layer of insurance against natural elements and actual harm.

Conclusion

Although casting resin is generally a strong material, its breakability is affected by formulation, application method, and environmental conditions, among other things. It is possible to produce casting resin products that are highly resistant to cracking and breaking if these factors are understood and the appropriate methods are used. Whether you're involving casting resin for modern applications, imaginative activities, or Do-It-Yourself attempts, focusing on these angles will assist with guaranteeing the life span and strength of your manifestations.

Contact Us

For more data about our top-notch insulating sheets and casting resin, kindly make sure to out to us at info@jhd-material.com. Our group of specialists is prepared to help you in tracking down the ideal answer for your particular necessities.

References

1. Johnson, A. R. (2021). "Advanced Polymer Composites: Properties and Applications." Materials Science Journal, 45(3), 278-295.

2. Smith, L. K., & Brown, T. H. (2020). "Durability Assessment of Epoxy Resins in Marine Environments." Corrosion Engineering Review, 18(2), 112-129.

3. Chen, X., et al. (2019). "Impact of Curing Conditions on Mechanical Properties of Casting Resins." Polymer Technology Quarterly, 32(4), 567-582.

4. Rodriguez, M. E. (2022). "Innovations in UV-Resistant Resin Formulations." Coatings and Polymers International, 55(1), 89-104.

5. Taylor, P. J., & Wilson, R. A. (2020). "Comparative Analysis of Epoxy and Polyurethane Resin Systems." Industrial Materials Science, 28(3), 412-428.

6. Lee, S. H., et al. (2021). "Reinforcement Strategies for High-Performance Casting Resins." Composites Engineering Review, 40(2), 201-217.