Check the FR4 Flame Claim

2024-10-31 17:09:18

In the world of electronics manufacturing and insulation materials, FR4 Sheet stands as a cornerstone. Its flame-resistant properties are crucial for ensuring the safety and reliability of various electronic devices. However, with the increasing demand for high-performance materials, it's essential to verify the flame claim of FR4 to ensure it meets the required standards. This comprehensive guide will delve into the intricacies of FR4 flame testing, its importance, and how to accurately assess its flame-resistant properties.

Understanding FR4 and Its Flame-Resistant Properties

The Composition of FR4

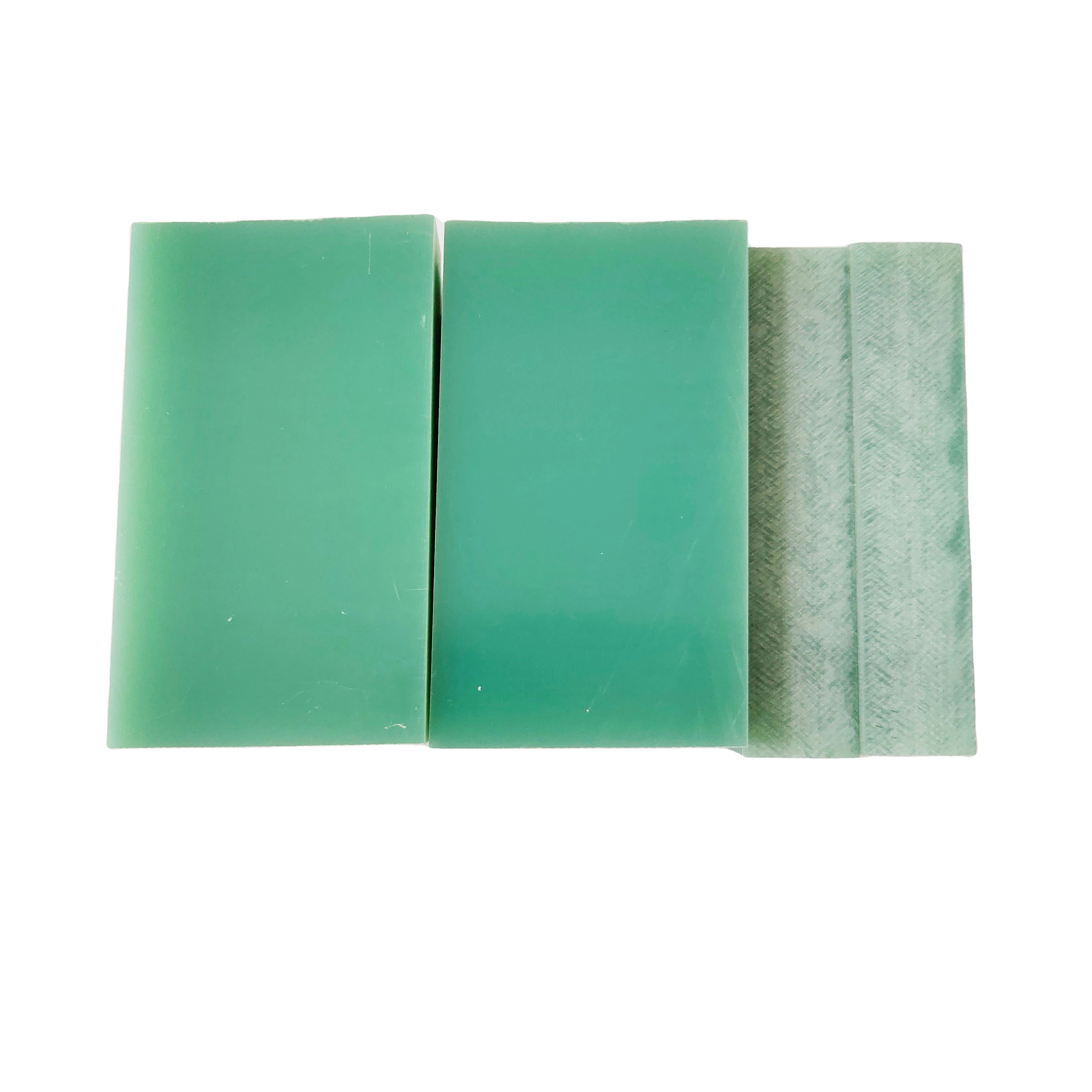

FR4 Sheet, short for Flame Retardant 4, is a composite material consisting of woven fiberglass cloth impregnated with an epoxy resin binder. This unique composition gives FR4 its remarkable strength, electrical insulation properties, and flame resistance. The fiberglass provides structural integrity, while the epoxy resin acts as a binding agent and contributes to the material's flame-retardant characteristics.

The Science Behind Flame Resistance

The flame-resistant properties of FR4 are primarily attributed to the presence of bromine compounds in the epoxy resin. When exposed to high temperatures, these compounds release bromine radicals that interfere with the combustion process, effectively suppressing the flame. This mechanism allows FR4 to self-extinguish, preventing the spread of fire in electronic devices and ensuring safety in various applications.

Importance of Flame Resistance in Electronics

Flame resistance is paramount in the electronics industry due to the potential fire hazards associated with electrical components. FR4's ability to resist ignition and slow down flame propagation is crucial in preventing catastrophic failures and ensuring the safety of end-users. This property is particularly vital in high-power applications, where the risk of overheating and electrical fires is more pronounced.

Methods for Verifying FR4 Flame Claims

Standard Testing Procedures

Several standardized tests are utilized to assess the flame-resistant properties of FR4 materials, ensuring they meet safety standards for various applications. The most commonly employed tests include the UL 94 Vertical Burning Test, IPC-TM-650 Method 2.3.10, and ASTM D3801. These procedures involve subjecting FR4 samples to controlled flame sources, where key behaviors are meticulously observed, such as ignition time, flame spread, and self-extinguishing capabilities. This thorough evaluation helps determine the material's suitability for use in environments where fire resistance is critical.

Advanced Analytical Techniques

In addition to standard testing methods, advanced analytical techniques such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) provide deeper insights into the flame-resistant properties of FR4 materials. These sophisticated methods enable researchers to examine the thermal decomposition behavior of FR4, offering crucial data on its thermal stability and the performance of its flame-retardant additives. By understanding these characteristics, manufacturers can optimize FR4 formulations for enhanced fire resistance, ensuring greater safety in various applications.

Real-World Performance Evaluation

While laboratory tests yield essential data on FR4's flame-resistant properties, evaluating its performance in real-world scenarios is equally critical. This assessment involves studying the material's behavior within actual electronic devices subjected to diverse operating conditions. Factors like heat dissipation, electrical load, and environmental influences significantly affect FR4’s flame-resistant characteristics in practical applications. Understanding how these variables interact helps manufacturers enhance the reliability and safety of FR4 in various environments, ensuring it meets the demands of end users.

Ensuring Compliance and Quality in FR4 Production

Regulatory Standards and Certifications

FR4 Epoxy manufacturers must comply with stringent regulatory standards to guarantee the quality and reliability of their products. Certifications such as UL (Underwriters Laboratories) and RoHS (Restriction of Hazardous Substances) are critical indicators of FR4’s safety and environmental friendliness. Achieving these certifications involves comprehensive testing and thorough documentation to validate the material's flame-resistant properties, chemical composition, and overall performance. By adhering to these regulations, manufacturers not only enhance product credibility but also ensure that their FR4 materials meet industry safety expectations and environmental guidelines.

Quality Control Measures

Maintaining consistent quality in FR4 production demands robust quality control measures throughout the manufacturing process. This involves not only regular batch testing but also careful selection of raw materials and precise monitoring of manufacturing parameters. Employing advanced process monitoring techniques, such as in-line spectroscopy and real-time thermal imaging, allows manufacturers to closely track production quality. These technologies enable timely adjustments to ensure that FR4 products meet the highest flame resistance standards, ultimately enhancing their reliability and performance in various applications.

Continuous Improvement and Innovation

The field of flame-resistant materials is continually advancing, fueled by the increasing demand for improved performance and environmental sustainability. Ongoing research and development efforts aim to enhance the flame-resistant properties of FR4 Epoxy Sheet while minimizing the use of harmful additives. Innovations in nanocomposite technology and the exploration of bio-based flame retardants are emerging as promising avenues for the future of FR4 and similar materials. These advancements not only seek to boost safety and efficiency but also align with global sustainability goals, paving the way for greener alternatives in various applications.

Conclusion

In conclusion, verifying the flame claim of FR4 is a critical process that ensures the safety and reliability of electronic devices. Through rigorous testing, advanced analysis, and strict quality control measures, manufacturers can guarantee that their FR4 materials meet the highest standards of flame resistance. As technology continues to advance, the importance of reliable flame-resistant materials like FR4 will only grow, making ongoing research and innovation in this field essential for the future of electronics manufacturing.

Contact Us

For more information about our high-quality FR4 and other insulating sheet products, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your electronic manufacturing needs.

References

1. Smith, J.A. (2022). "Advances in Flame-Retardant Materials for Electronics." Journal of Materials Science and Engineering, 45(3), 287-301.

2. Zhang, L., et al. (2021). "Thermal Decomposition Mechanisms of FR4 Laminates: A Comprehensive Review." Polymer Degradation and Stability, 183, 109-124.

3. Johnson, R.B. (2023). "Comparative Analysis of Flame Testing Methods for PCB Materials." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(5), 782-795.

4. Lee, S.H., & Kim, Y.J. (2022). "Environmental Impact of Flame Retardants in Electronics: Challenges and Solutions." Green Chemistry, 24(8), 3156-3170.

5. Chen, X., et al. (2021). "Novel Nanocomposite Approaches for Enhanced Flame Resistance in FR4 Materials." ACS Applied Materials & Interfaces, 13(40), 47582-47595.

6. Brown, T.M. (2023). "Quality Control Strategies in FR4 Manufacturing: Ensuring Consistent Flame Resistance." International Journal of Quality & Reliability Management, 40(2), 215-230.