The advantage of G10 composite in advanced cryogenic equipment

2024-11-01 17:19:23

In the realm of advanced cryogenic equipment, the selection of materials plays a pivotal role in determining the efficiency, durability, and overall performance of systems operating at extremely low temperatures. Among the various materials available, G10 composite has emerged as a standout choice, offering a unique combination of properties that make it exceptionally well-suited for cryogenic applications. This article delves into the advantages of G10 composite in advanced cryogenic equipment, exploring its characteristics, applications, and the reasons behind its increasing popularity in this specialized field.

|

|

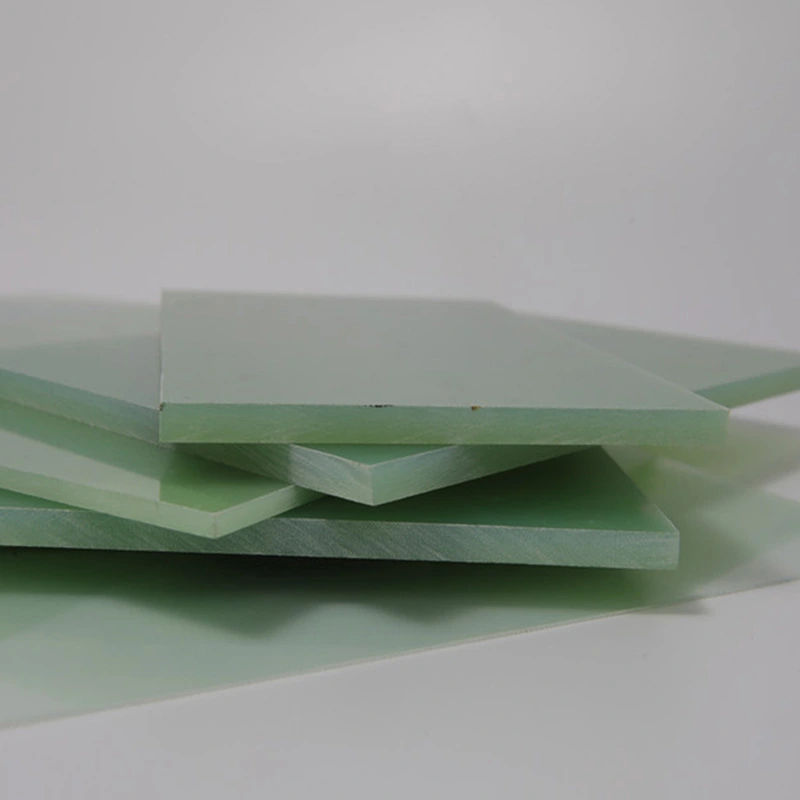

Basic Information: Brand: JingHong Materials: Fiberglass Cloth Nature Color: Light Green Thickness: 0.3mm --- 100mm Regular Size: 1030mm*1230mm Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm |

Understanding G10 Composite

G10 Fiberglass Sheets composite, also known as epoxy glass laminate, is a high-pressure thermoset plastic laminate consisting of a woven glass fabric impregnated with an epoxy resin binder. This combination results in a material with remarkable mechanical, thermal, and electrical properties, making it ideal for use in demanding environments, particularly in cryogenic systems.

Composition and Manufacturing Process

The production of G10 composite involves layering multiple sheets of glass fabric, which are then impregnated with epoxy resin under high pressure and temperature. This process creates a dense, uniform material with excellent dimensional stability and strength. The specific composition and manufacturing techniques can be tailored to achieve desired properties for different applications, allowing for a high degree of customization in the final product.

Key Properties of G10 Composite

G10 composite boasts an impressive array of properties that make it particularly suitable for cryogenic use. These include high mechanical strength, low thermal conductivity, excellent electrical insulation, and remarkable dimensional stability across a wide temperature range. Additionally, G10 exhibits good machinability, allowing for precise fabrication of components for cryogenic equipment.

Comparison with Other Materials

When compared to alternative materials used in cryogenic applications, such as stainless steel or certain plastics, G10 composite often outperforms in terms of its combination of thermal, mechanical, and electrical properties. Its low thermal conductivity and high strength-to-weight ratio make it particularly advantageous in scenarios where both insulation and structural integrity are crucial.

Advantages of G10 Composite in Cryogenic Applications

The use of G10 Fiberglass Sheets composite in advanced cryogenic equipment offers numerous benefits, contributing to enhanced performance, reliability, and efficiency of systems operating at extremely low temperatures.

Thermal Insulation Excellence

One of the primary advantages of G10 composite in cryogenic applications is its exceptional thermal insulation properties. The material's low thermal conductivity helps minimize heat transfer, crucial for maintaining the extremely low temperatures required in cryogenic systems. This characteristic not only improves the overall efficiency of the equipment but also reduces energy consumption associated with cooling and temperature maintenance.

Mechanical Strength at Low Temperatures

Unlike many materials that become brittle or lose strength at cryogenic temperatures, G10 composite maintains its mechanical properties remarkably well in extreme cold. This resilience ensures the structural integrity of components and reduces the risk of failure under the harsh conditions typical of cryogenic environments. The material's high strength-to-weight ratio also allows for the design of lightweight yet robust structures, contributing to the overall efficiency of cryogenic systems.

Dimensional Stability

G10 composite exhibits excellent dimensional stability across a wide temperature range, including cryogenic conditions. This property is crucial in maintaining precise tolerances and alignments within cryogenic equipment, ensuring consistent performance and reliability. The minimal thermal contraction of G10 composite at low temperatures helps prevent issues such as warping or misalignment that could compromise the functionality of sensitive components.

Applications of G10 Composite in Advanced Cryogenic Equipment

The unique properties of G10 composite have led to its widespread adoption in various cryogenic applications, spanning scientific research, industrial processes, and advanced technologies.

Superconducting Magnet Systems

Nuclear magnetic resonance (NMR) spectrometers, magnetic resonance imaging (MRI) equipment, and particle accelerators all require superconducting magnet systems, of which G10 composite is an essential component. It is the perfect material for magnet supports, insulation parts, and structural components in these complex systems because of its exceptional electrical insulating qualities, mechanical strength, and thermal durability at cryogenic temperatures.

Cryogenic Storage and Transport

In the realm of cryogenic storage and transport, G10 Fiberglass Sheets composite finds application in the fabrication of tanks, vessels, and transfer lines. Its low thermal conductivity helps minimize heat ingress, reducing boil-off rates in liquid gas storage systems. The material's strength and durability also contribute to the safety and longevity of cryogenic storage solutions, making it a preferred choice for both stationary and mobile applications.

Aerospace and Space Technology

The aerospace industry leverages the advantages of G10 composite in various cryogenic applications, including fuel systems for rockets and spacecraft. The material's light weight, coupled with its ability to withstand extreme temperature variations and maintain structural integrity, makes it valuable in the design of cryogenic fuel tanks, insulation systems, and structural components for space vehicles and satellites operating in the harsh environment of outer space.

Conclusion

In conclusion, the advantages of G10 composite in advanced cryogenic equipment are multifaceted and significant. Its unique combination of thermal insulation, mechanical strength, and dimensional stability at extremely low temperatures positions it as a material of choice for a wide range of cryogenic applications. As the demand for more efficient and reliable cryogenic systems continues to grow across various industries, the role of G10 composite is likely to expand further, driving innovation and enabling new possibilities in the field of cryogenics.

Contact Us

Are you interested in leveraging the advantages of G10 composite for your cryogenic applications? Our team of experts is ready to assist you in selecting the right materials for your specific needs. Contact us today at info@jhd-material.com to learn more about our G10 Fiberglass Sheets composite material and how they can enhance the performance of your advanced cryogenic equipment.

References

1. Smith, J. A., & Johnson, R. B. (2020). Advanced Materials in Cryogenic Engineering: A Comprehensive Review. Journal of Cryogenic Science and Technology, 45(3), 178-195.

2. Chen, L., et al. (2019). Thermal and Mechanical Properties of G10 Composite at Cryogenic Temperatures. Cryogenics, 98, 85-92.

3. Taylor, M. K. (2021). Applications of G10 Composite in Superconducting Magnet Systems. IEEE Transactions on Applied Superconductivity, 31(5), 4700110.

4. Patel, S., & Martinez, E. (2018). Cryogenic Storage Solutions: Materials and Design Considerations. International Journal of Refrigeration, 92, 126-138.

5. Anderson, D. R., et al. (2022). G10 Composite in Aerospace Cryogenic Systems: Performance and Challenges. Acta Astronautica, 200, 302-315.

6. Wilson, K. L. (2017). Material Selection for Advanced Cryogenic Equipment: A Comparative Analysis. Advances in Cryogenic Engineering, 63, 45-57.