CE Phenolic Sheet | Benefits Across Industries

2024-11-21 17:14:19

In the world of industrial materials, CE phenolic sheets have emerged as a versatile and indispensable component across various sectors. These high-performance laminates offer a unique combination of properties that make them suitable for a wide range of applications. This article delves into the multifaceted benefits of CE phenolic sheets and explores their impact on different industries.

Understanding CE Phenolic Sheets

Composition and Manufacturing Process

CE phenolic sheets are crafted from layers of paper or fabric impregnated with phenolic resin. The manufacturing process involves subjecting these layers to high pressure and temperature, resulting in a dense, durable material. This process imbues the sheets with their characteristic strength and resistance to various environmental factors.

Key Properties

CE phenolic sheets boast an impressive array of properties that contribute to their widespread adoption. These include exceptional mechanical strength, low thermal conductivity, excellent electrical insulation, and remarkable resistance to chemicals, heat, and flame. Such a combination of attributes makes them a preferred choice in demanding industrial environments.

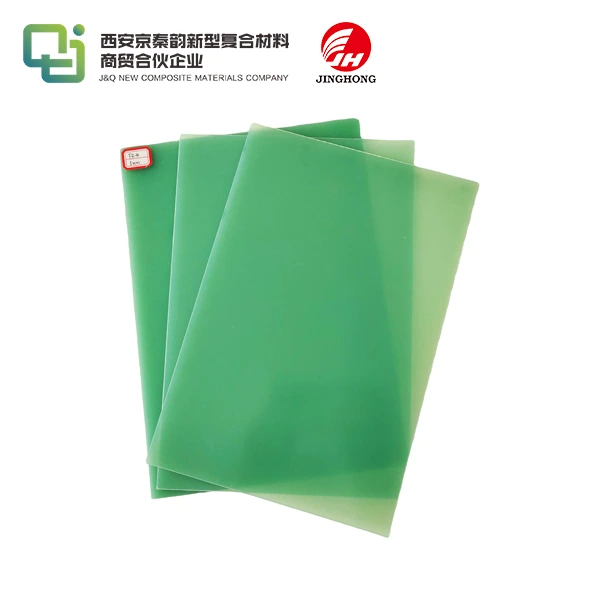

Grades and Variations

Manufacturers produce CE phenolic sheets in various grades and specifications to cater to diverse industrial needs. These variations may include differences in thickness, color, surface finish, and specific performance characteristics. The availability of customized options allows industries to select the most suitable phenolic sheet for their particular applications.

Applications Across Industries

Electrical and Electronics Sector

In the electrical and electronics industry, CE phenolic sheets play a crucial role as insulating materials. Their high dielectric strength and low moisture absorption make them ideal for manufacturing switchboards, circuit breakers, and other electrical components. The sheets' ability to withstand high temperatures without compromising their insulating properties ensures the safety and reliability of electrical systems.

Aerospace and Defense

The aerospace and defense sectors rely on CE phenolic sheets for their exceptional strength-to-weight ratio and fire-resistant properties. These materials find applications in aircraft interiors, missile components, and radar systems. The sheets' ability to maintain their structural integrity under extreme conditions makes them invaluable in these high-stakes industries.

Automotive Manufacturing

Automotive manufacturers utilize CE phenolic sheets in various components, including brake pads, clutch facings, and gaskets. The material's resistance to wear, heat, and chemicals ensures longevity and reliability in these critical automotive parts. Additionally, the sheets' lightweight nature contributes to overall vehicle efficiency.

Benefits of CE Phenolic Sheets

Thermal Management

One of the standout benefits of CE phenolic sheets is their exceptional thermal management capabilities. The material's low thermal conductivity makes it an excellent insulator, preventing heat transfer in various applications. This property is particularly valuable in industries where temperature control is crucial, such as in the manufacturing of heating equipment or in thermal insulation for buildings.

Chemical Resistance

CE phenolic sheets exhibit remarkable resistance to a wide range of chemicals, including acids, solvents, and oils. This resistance makes them suitable for use in harsh chemical environments, such as in the production of storage tanks, laboratory equipment, and chemical processing facilities. The sheets' ability to maintain their integrity when exposed to corrosive substances ensures longevity and safety in these applications.

Dimensional Stability

Another significant advantage of CE phenolic sheets is their excellent dimensional stability. These materials maintain their shape and size even when subjected to varying temperatures and humidity levels. This property is crucial in applications where precision and consistency are paramount, such as in the manufacturing of machine parts or in the construction of structural components for buildings and vehicles.

Environmental Considerations

Sustainability in Production

As industries increasingly focus on sustainability, the production of CE phenolic sheets has adapted to incorporate more environmentally friendly practices. Some manufacturers are exploring the use of bio-based resins and recycled materials in the production process, aiming to reduce the carbon footprint associated with these versatile sheets.

Recyclability and End-of-Life Management

While CE phenolic sheets offer durability and longevity, their end-of-life management presents challenges. Research is ongoing to develop effective recycling methods for these materials. Some innovative approaches include grinding the sheets for use as fillers in other products or utilizing them in energy recovery processes.

Regulatory Compliance

Manufacturers of CE phenolic sheets must adhere to various environmental regulations and standards. This includes compliance with restrictions on hazardous substances and adherence to emission control guidelines during production. Such regulatory compliance ensures that the benefits of these materials are realized without compromising environmental integrity.

Future Trends and Innovations

Advanced Composites

The future of CE phenolic sheets lies in the development of advanced composites. Researchers are exploring ways to enhance the sheets' properties by incorporating nanomaterials or combining them with other high-performance polymers. These innovations aim to create materials with even greater strength, lighter weight, and improved functionality.

Smart Materials Integration

An exciting area of development involves integrating smart technologies into CE phenolic sheets. This could include embedding sensors for real-time monitoring of stress, temperature, or other environmental factors. Such advancements would open up new possibilities for predictive maintenance and enhanced performance in various applications.

Customization and Tailored Solutions

As industries continue to evolve, the demand for customized CE phenolic sheets is likely to grow. Manufacturers are investing in technologies that allow for greater flexibility in production, enabling them to create sheets with specific properties tailored to unique industrial requirements. This trend towards customization will further expand the applications of these versatile materials.

Conclusion

CE phenolic sheets have proven their worth across numerous industries, offering a unique combination of strength, durability, and versatility. From electrical insulation to aerospace components, these materials continue to play a crucial role in advancing technological and industrial capabilities. As research and innovation progress, CE phenolic sheets are poised to evolve, meeting the changing needs of industries while addressing environmental concerns. Their enduring popularity and ongoing development underscore their significance in shaping the future of industrial materials.

Contact Us

For more information about our range of CE phenolic sheets and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your industrial needs.

References

1. Johnson, R. (2022). Advanced Materials in Industrial Applications: A Comprehensive Guide.

2. Smith, A. et al. (2021). Thermal Management Solutions for Modern Electronics.

3. Brown, L. (2023). Innovations in Aerospace Materials: From Concept to Implementation.

4. Zhang, Y. (2022). Sustainable Practices in Industrial Material Production.

5. Davis, M. (2021). Chemical Resistance Properties of Modern Polymers and Composites.

6. Thompson, K. (2023). The Future of Smart Materials in Manufacturing.