Can G10 fiberglass tubes withstand high temperatures?

2024-09-23 17:03:20

When considering materials for industrial use, especially in environments that involve high temperatures, it’s critical to choose components that can withstand extreme conditions without losing performance. For industries relying on durable insulation and structural integrity, G10 fiberglass tubes, along with FR4 fiberglass tubes or FR4 epoxy tubes, have become popular choices due to their impressive thermal resistance and mechanical strength. But how well do these tubes fare under high temperatures? Let’s explore the temperature resilience of G10 fiberglass tubes and why they might be the ideal solution for your industrial needs.

What Are G10 Fiberglass Tubes?

Composition and Structure of G10 Fiberglass Tubes

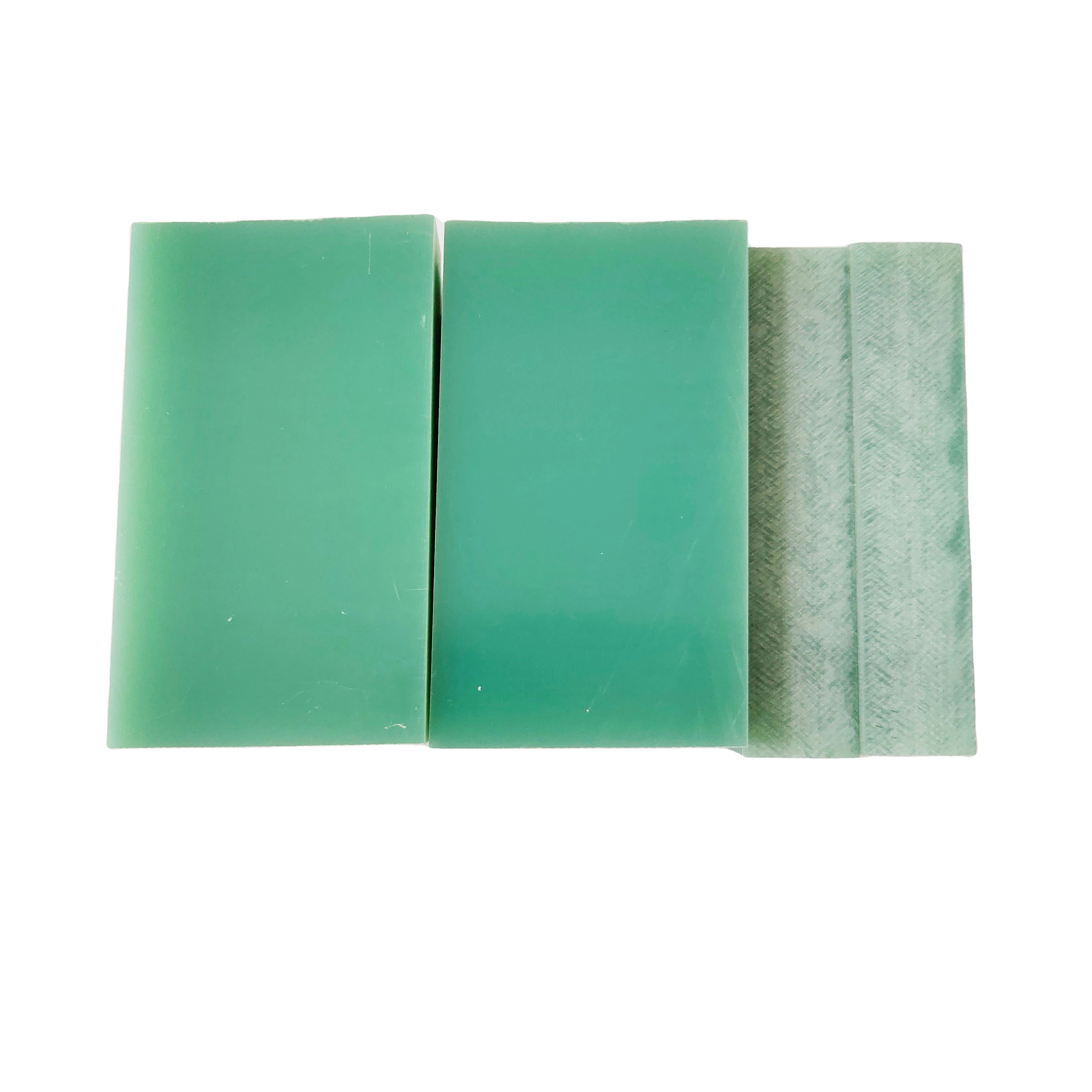

G10 fiberglass tubes are made by layering woven glass fabric with an epoxy resin, which is then cured under high pressure and heat. The result is a material with excellent mechanical properties, including high tensile strength, electrical insulation, and chemical resistance. The epoxy resin used in these tubes contributes to their impressive thermal performance, making them a popular choice for industries where both durability and heat resistance are required.

How G10 Fiberglass Differs from FR4

While G10 and FR4 fiberglass tubes share several similarities, the primary difference lies in their flame-retardant properties. FR4, an upgrade of G10, includes a flame-retardant bromine additive that enhances its fire resistance. This makes FR4 fiberglass tubes and FR4 epoxy tubes better suited for environments where the risk of fire is a concern. However, both materials offer solid performance at high temperatures, which we will explore further below.

Common Applications of G10 Fiberglass Tubes

Thanks to their versatility and strength, G10 fiberglass tubes are used across various industries, including electronics, aerospace, marine, and heavy machinery. Their ability to maintain structural integrity under stress—while providing electrical insulation and resistance to chemicals—makes them invaluable in harsh environments such as power generation facilities, oil refineries, and electronic enclosures.

Can G10 Fiberglass Tubes Withstand High Temperatures?

Heat Resistance of G10 Fiberglass Tubes

One of the most important characteristics of G10 fiberglass tubes is their ability to withstand high temperatures without losing their structural or electrical insulation properties. These tubes can typically endure continuous heat exposure of up to 130°C (266°F), with short-term exposure tolerances reaching even higher. This makes them suitable for applications where components are exposed to sustained heat levels, such as in electrical insulation systems or engine components.

FR4 Fiberglass Tubes: An Even Higher Heat Tolerance

As an enhancement of G10, FR4 epoxy tubes offer even greater thermal stability. Their flame-retardant properties allow them to endure temperatures as high as 140°C to 150°C (284°F - 302°F) without compromising their integrity. In environments where both heat and fire resistance are major concerns—such as aerospace, automotive, or industrial electrical systems—FR4 tubes may offer a better solution.

Factors That Affect Heat Performance

While G10 and FR4 fiberglass tubes are highly heat-resistant, it’s important to consider the specific working environment. Factors such as the duration of heat exposure, the presence of moisture, and mechanical stress can affect the performance of these tubes. In general, G10 and FR4 maintain their rigidity and insulation capabilities under high-temperature conditions, but their performance can vary depending on the specific demands of the application.

Why Choose G10 Fiberglass Tubes for High-Temperature Applications?

Durability and Stability in Harsh Conditions

G10 fiberglass tubes are known for their durability, even in challenging environments where heat, moisture, and chemicals are constant factors. Their ability to withstand high temperatures, combined with their mechanical strength, makes them ideal for use in industrial settings where materials are constantly exposed to harsh conditions. Whether in oil rigs, power plants, or heavy machinery, G10 tubes provide reliable performance over time, reducing the need for frequent maintenance or replacements.

Electrical Insulation at High Temperatures

One of the standout features of G10 fiberglass tubes is their excellent electrical insulation properties, even at elevated temperatures. This makes them the material of choice for applications like electrical transformers, switchgear, and circuit breakers, where heat is generated during operation. The high dielectric strength of G10 ensures that electrical systems remain safe and functional, even when temperatures rise.

FR4 Tubes Offer Enhanced Fire Safety

For industries where fire safety is paramount, FR4 fiberglass tubes provide an added layer of protection. Their flame-retardant properties ensure that they won’t ignite or propagate flames, offering peace of mind in environments like aerospace, automotive, or power generation equipment. This is particularly important in situations where electrical sparks or high temperatures could pose a fire hazard.

Conclusion

To answer the question, Yes, G10 fiberglass tubes can withstand high temperatures, making them suitable for a wide range of industrial applications. With continuous heat resistance up to 130°C (266°F) and short-term exposure tolerances even higher, G10 fiberglass tubes perform exceptionally well in heat-intensive environments. Additionally, FR4 fiberglass tubes offer enhanced fire resistance and even greater temperature tolerance, reaching up to 150°C (302°F). Both materials are reliable choices for industries that demand durability, electrical insulation, and thermal stability. Whether you're in the aerospace, electrical, or heavy machinery sectors, G10 fiberglass tubes and FR4 epoxy tubes provide the essential characteristics needed to maintain performance in extreme conditions.

Contact Us

At J&Q, we have over 20 years of experience producing and selling high-performance insulating materials, including G10 and FR4 fiberglass tubes. With a global reach and a commitment to quality, we are equipped to meet your industrial needs with reliable, durable products. If you're looking for more information or need assistance selecting the right fiberglass tube for your specific application, don't hesitate to reach out to us. Contact us today at info@jhd-material.com for expert advice and high-quality fiberglass solutions.

References

1. "Fiberglass Reinforced Plastics: Design and Applications," by Richard P. P. Feynman.

2. "Heat-Resistant Materials Handbook," edited by George E. Totten.

3. "Industrial Insulation Materials and Applications," by John F. Malloy.

4. "Epoxy Resin Technology," by Paul F. Bruins.

5. "Composite Materials: Properties, Performance, and Applications," by Deborah D. L. Chung.

6. "Electrical Insulation for Rotating Machines: Design and Applications," by Greg C. Stone and Edward A. Boulter.