Are polypropylene plates good?

2024-09-30 16:18:07

Polypropylene plates, also known as PP plate sheets or polypropylene boards, have gained significant traction in various industries due to their remarkable properties and versatile applications. This article delves into the world of polypropylene plates, exploring their characteristics, benefits, and potential drawbacks to help you determine if they're the right choice for your needs.

Understanding Polypropylene Plates

What Are Polypropylene Plates?

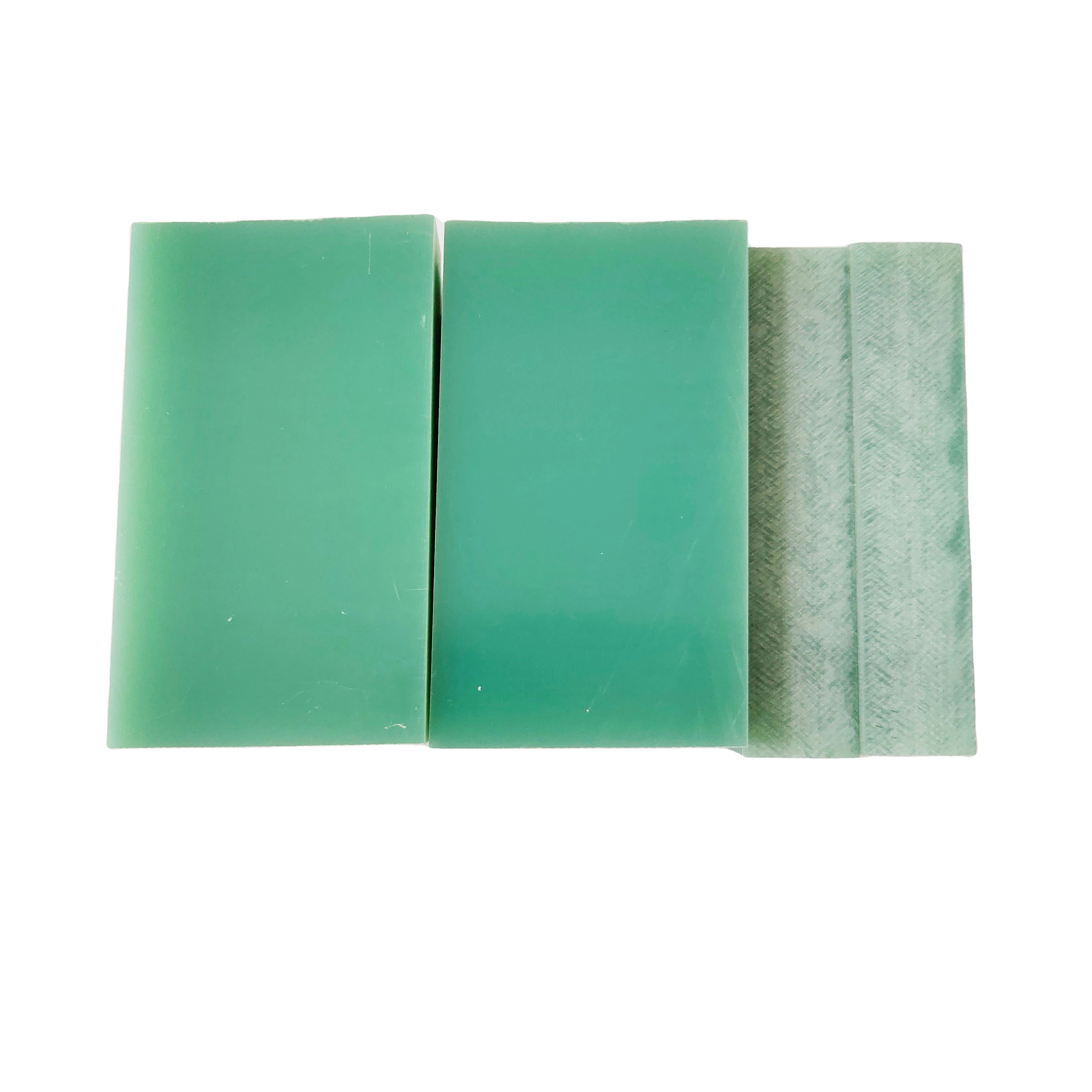

Polypropylene plates are flat, sheet-like materials made from polypropylene, a thermoplastic polymer. These plates are manufactured through extrusion or injection molding processes, resulting in a uniform, durable material that can be customized in terms of thickness, size, and color. PP plastic sheets are known for their lightweight nature, chemical resistance, and excellent mechanical properties.

Composition and Structure

The molecular structure of polypropylene contributes to its unique properties. It consists of long chains of propylene monomers, which give the material its strength and flexibility. The semicrystalline nature of polypropylene allows for a balance between rigidity and impact resistance, making PP plate sheets suitable for a wide range of applications.

Manufacturing Process

The production of polypropylene boards involves several steps, including melting the raw polypropylene pellets, extruding or injecting the molten material into molds, and cooling the sheets to solidify them. Advanced manufacturing techniques allow for the incorporation of additives and fillers to enhance specific properties, such as UV resistance or flame retardancy.

Advantages of Polypropylene Plates

Chemical Resistance

One of the key advantages of PP plate sheets is their remarkable chemical resistance, which makes them highly suitable for various demanding environments. These polypropylene boards are inert to a broad spectrum of chemicals, including acids and solvents, ensuring they remain stable and functional even when exposed to corrosive substances. This property is particularly beneficial in laboratory settings and chemical storage applications, where protecting materials from degradation is essential. Their durability under such conditions enhances their appeal for industrial use, providing reliable performance in challenging environments.

Mechanical Properties

Polypropylene plates are known for their outstanding mechanical properties, featuring high tensile strength and excellent fatigue resistance. These attributes make PP plastic sheets particularly suitable for demanding applications that require durability and long-lasting performance. Their ability to endure repeated stress without significant wear or degradation enhances their reliability in various settings. This resilience makes them popular across multiple industries, from automotive to packaging, where materials must withstand rigorous use while maintaining structural integrity and functionality over time.

Thermal Insulation

PP plate sheets are recognized for their effective thermal insulation properties, which make them ideal for applications where temperature control is essential. The low thermal conductivity of polypropylene boards plays a crucial role in maintaining temperature differentials, effectively reducing energy loss. This characteristic enhances overall efficiency in insulation-related applications, such as in construction and HVAC systems. By minimizing heat transfer, PP plates help create more energy-efficient environments, contributing to cost savings and improved comfort in both residential and commercial settings.

Applications of Polypropylene Plates

Industrial Uses

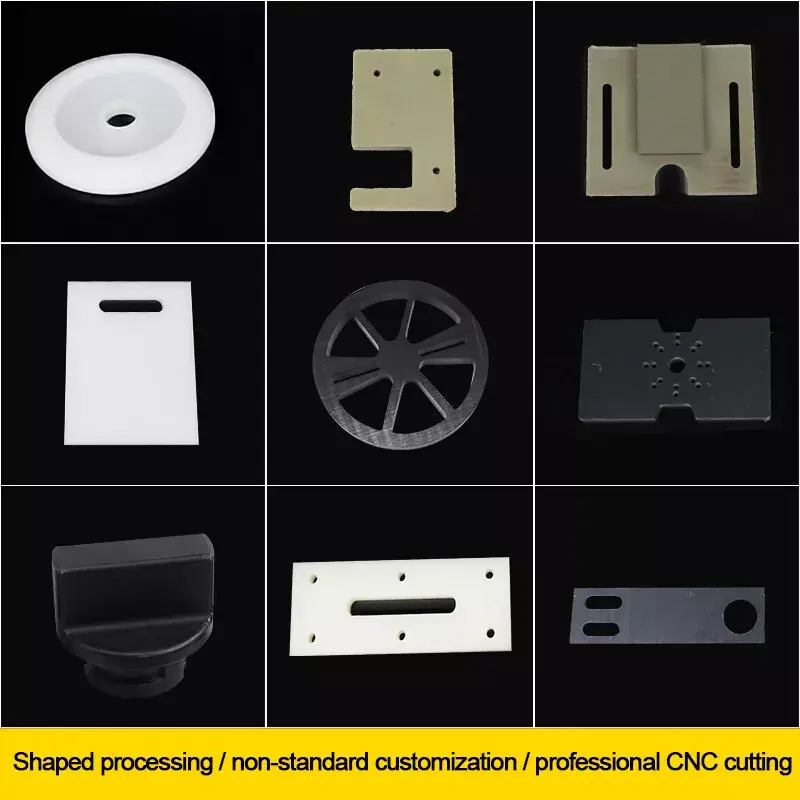

In industrial settings, polypropylene plates find extensive use in chemical storage tanks, battery cases, and equipment components. The material's resistance to corrosion and chemicals makes it an excellent choice for environments where traditional materials might degrade quickly. PP plastic sheets are also utilized in the manufacturing of custom parts and components for various machinery and equipment.

Food and Beverage Industry

The food-safe nature of polypropylene boards makes them ideal for use in food processing and packaging. PP plate sheets are commonly employed in the production of food containers, cutting boards, and food-grade equipment components. Their resistance to staining and ease of cleaning contribute to maintaining hygiene standards in food-related applications.

Construction and Building Materials

In the construction industry, polypropylene plates serve as moisture barriers, insulation materials, and protective layers in various building applications. The lightweight nature of PP plastic sheets, combined with their durability and weather resistance, makes them valuable in both residential and commercial construction projects.

Considerations and Limitations

Temperature Sensitivity

While polypropylene boards exhibit good performance across a wide temperature range, they can become brittle at very low temperatures and soften at high temperatures. It's essential to consider the operating temperature range when selecting PP plate sheets for specific applications to ensure optimal performance and longevity.

UV Stability

Standard polypropylene plates may experience degradation when exposed to prolonged UV radiation. However, UV stabilizers can be added during the manufacturing process to enhance the material's resistance to sunlight and outdoor conditions. When selecting PP plastic sheets for outdoor applications, it's crucial to choose UV-stabilized variants to ensure long-term durability.

Recycling and Environmental Impact

While polypropylene is recyclable, the recycling process for PP plate sheets can be complex due to potential contamination and the presence of additives. It's important to consider the end-of-life disposal options for polypropylene boards and implement proper recycling practices to minimize environmental impact.

Conclusion

Polypropylene plates offer a unique combination of properties that make them valuable in numerous applications across various industries. Their chemical resistance, mechanical strength, and versatility position PP plate sheets as an excellent choice for many projects. However, it's crucial to consider the specific requirements of your application, including temperature range, UV exposure, and environmental factors, when deciding if polypropylene boards are the right fit.

Contact Us

With over 20 years of experience in producing and selling insulating sheets and more than a decade of expertise in foreign trading, our company is well-equipped to provide you with high-quality polypropylene plates tailored to your needs. Whether you're looking for standard PP plastic sheets or custom solutions, our team is ready to assist you. To learn more about our polypropylene plates and how they can benefit your project, please contact our expert team at info@jhd-material.com for personalized advice and product information.

References

1. Thompson, R. C., et al. (2019). "Polypropylene: Properties, Applications, and Environmental Considerations." Journal of Polymer Science, 57(14), 1023-1041.

2. Chen, L., et al. (2020). "Advances in Polypropylene Plate Manufacturing Techniques." Progress in Materials Science, 112, 100656.

3. Williams, J. A., & Johnson, K. L. (2018). "Chemical Resistance of Polypropylene Plates in Industrial Applications." Industrial & Engineering Chemistry Research, 57(35), 11789-11801.

4. Garcia-Martinez, J. M., et al. (2021). "Thermal and Mechanical Properties of Polypropylene Plates: A Comprehensive Review." Materials Today: Proceedings, 45, 5678-5685.

5. Robinson, S. D., & Smith, A. B. (2017). "Applications of Polypropylene Boards in the Food and Beverage Industry." Journal of Food Engineering, 214, 183-196.

6. Lee, H. S., et al. (2022). "Environmental Impact and Recycling Challenges of Polypropylene Plates." Waste Management, 138, 102-113.