Application of CNC Engraving Machine in Fixture Industry

2022-11-30

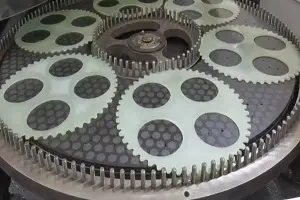

1. CNC engraving machine & industrial fixture

Some types of jigs are also called "molds" or "assistive tools", whose main purpose is to repeat the reproduction of a certain part for repeatability and accuracy. It has been widely used before the industrial age, including mechanical jigs, woodworking jigs, welding jigs, jewelry jigs, and other fields.

The reason why CNC machine tools can be widely used in the manufacturing industry is mainly because its servo controller has the ability to automatically move tools to the correct position, which provides a powerful aid for machining and manufacturing jigs.

2. Classification of fixture materials

Fixture materials are divided into metal and non-metallic materials. Today, we will talk about the application specifications of CNC engraving machine in non-metallic material fixture industry.

3. Acrylic

Acrylic, also known as acrylic and plexiglass, with chemical name of PMMA, is a kind of plastic product. The utility model can be used as a fixture roof plate, a needle plate, a mechanism plate which needs transparency, etc. When using the engraving machine to process the material with a fixture, due to its characteristics, the following points should be noted:

a) In order to prevent edge collapse, it shall be processed by down milling

b) For tapping, the bottom hole shall be deepened and new tapping shall be used and lubricated

c) The machined surface shall be polished with polishing agent

Bakelite (PF-ESD), also known as phenolic plastic, is the first type of plastic to be put into industrial production. It is widely used in fixture industry because of its high mechanical strength, good insulation, heat resistance and corrosion resistance. It is cheap and easy to process. It is usually made into fixture structural parts, needle bearing plates without special requirements, light loaded moving connecting parts, etc. When using the carving machine to process the fixture of the electric board, the following points should be noted:

a) The edge is easy to collapse during processing, and the forward milling shall be used as far as possible

b) Since it is not convenient to install a tooth socket on the side tooth hole, please pay attention to oil lubrication and screw tapping to the end when tapping

c) It is easy to burn the cutter when processing domestic bakelite, please pay attention to coordinate the feed speed and feed amount

5. Glass fiber

Glass fiber is commonly known as FR4 sheet, which is not a material name, but a material grade. The common glass fiber used for processing in the market is actually called FR4 epoxy glass cloth laminate, which belongs to a kind of plastic. Like bakelite board, it has good mechanical strength, insulation and heat resistance, and can be used to make fixture structures, needle carrier plates, connectors, mounting parts, carriers, trays, etc.

When using the engraving machine to process glass fiber materials, the following points should be noted:

a) Dust is heavy during processing, pay attention to dust suction

b) If the tool wear is large and the tool is easy to burn, use cutting fluid as much as possible if conditions permit

c) Fiberglass board can be used for tapping, but tooth sockets shall be used for important connecting threaded holes as much as possible

d) Glass fiber is easy to cause itching when penetrating into pores, so pay attention to dust inhalation into skin during processing

6. POM

POM sheet is also a kind of plastic products. It has high rigidity, high hardness, excellent elasticity, and very good dimensional stability. It is often used to make parts and components such as fixture pressure bar, carrier plate, shaft sleeve, etc