Can FR4 Epoxy Sheets be used for structural reinforcement?

2024-06-06 16:35:15

Can FR4 Epoxy Sheets be used for Structural Reinforcement?

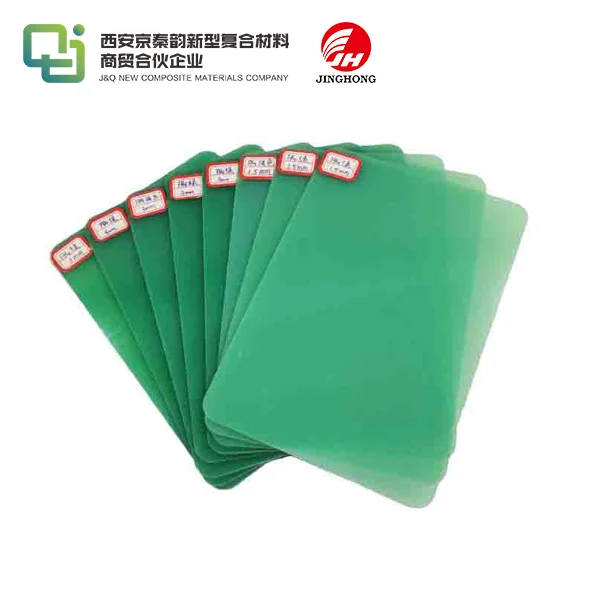

Epoxy Resin Sheets, which are made out of woven fiberglass and epoxy pitch, have gained notoriety for their exceptional mechanical strength and fire resistant properties. In any case, the use of FR4 for underlying support in development and different businesses requests a complete perception of its qualities and constraints. In this article, I plan to examine whether FR4 epoxy sheets can be effectively utilized for primary support, giving a top to bottom examination according to different viewpoints.

The boundless acknowledgment of FR4 epoxy sheets comes from their uncommon mechanical strength, making them engaging for underlying upgrade applications. Their high rigidity and protection from distortion under load add to their likely reasonableness for supporting designs exposed to huge pressure or strain.

The fire resistant properties of FR4 epoxy sheets make them invaluable for applications where fire wellbeing is fundamentally important. This trademark upgrades their allure for use in underlying support, especially in conditions where imperviousness to fire is urgent.

Understanding FR4 Material Properties

FR4 is a glass-epoxy cover that is made by consolidating fiberglass with an epoxy sap fastener. This material is profoundly respected for its uncommon mechanical strength, phenomenal electrical protection properties, and noteworthy warm security. With a particular gravity of roughly 1.85 g/cm³ and a most extreme temperature resilience of around 140°C (284°F), FR4 offers dependability in different applications.

The mechanical properties of FR4 Epoxy Sheet further add to its notoriety, with a flexural strength that can arrive at up to 60,000 psi and a compressive strength of roughly 55,000 psi. These hearty qualities settle on FR4 a favored decision in the hardware business, especially for the assembling of printed circuit sheets (PCBs).

In electronic applications, FR4's high mechanical strength guarantees the sturdiness and unwavering quality of PCBs, even in requesting functional conditions. Its brilliant electrical protection properties assist with forestalling electrical obstruction and guarantee ideal execution of electronic parts. Also, the material's warm strength permits it to endure heat created during electronic activities without undermining its primary honesty.

The blend of mechanical strength, electrical protection capacities, warm steadiness, and other helpful properties positions FR4 as a flexible and solid material for different electronic applications, making it a staple in the hardware business and a go-to decision for PCB producing.

FR4 in Industrial Applications

The flexibility of FR4 outperforms its conventional applications in the hardware area, venturing into a wide exhibit of modern fields. Its momentous layered solidness, intrinsic fire opposition, and ability to endure ecological difficulties render it a practical contender for different modern purposes.

In areas like aviation, car, and protection, where materials are exposed to outrageous circumstances and severe prerequisites, FR4 sheets have tracked down their place. The capacity of FR4 to keep up with its shape and design under shifting temperatures and tensions is pivotal in aviation applications, where accuracy and dependability are central. The intrinsic fire obstruction of FR4 goes with it an ideal decision for businesses where fire wellbeing is an essential concern, like in the auto area. FR4 Epoxy Sheets offer a degree of security against fire dangers, guaranteeing the wellbeing and trustworthiness of parts even in high-temperature conditions.

Moreover, the versatility of FR4 against natural stressors further upgrades its allure in modern settings. Whether confronting openness to dampness, synthetic compounds, or mechanical strain, FR4 exhibits sturdiness and life span, making it a trustworthy material for requesting applications across different ventures. FR4 has secured itself as a solid and flexible material in modern areas past gadgets, demonstrating its worth in applications where materials should get through cruel circumstances without compromising execution or primary honesty. Its versatility and remarkable properties keep on settling on it a favored decision for a great many modern applications.

Structural Reinforcement Capabilities

While Epoxy Resin Sheets has admirable properties like high mechanical strength, layered steadiness, and fire obstruction, its application for underlying support in development or related fields stays abnormal. The material's qualities are more qualified for insulative and strong jobs inside electronic arrangements as opposed to filling in as essential burden bearing parts in development.

In the development business, materials like steel and concentrated substantial composites are generally preferred for primary support because of their prevalent burden bearing limits and consistence with construction standards and guidelines. Steel, famous for its uncommon elasticity and strength, is in many cases the favored decision for supporting designs exposed to critical loads and stresses. Likewise, specific substantial composites offer a blend of high strength, malleability, and flexibility, making them appropriate for different primary applications.

Construction laws and industry guidelines frequently direct the materials and techniques to be utilized for underlying support, focusing on security, unwavering quality, and consistence with administrative necessities. While FR4 might offer specific helpful properties, it may not line up with the particular measures and execution norms commanded for primary support in development.

Challenges and Considerations

When considering FR4 for any structural applications, several challenges arise. The material's thermal expansion properties and susceptibility to environmental conditions may limit its effectiveness as a structural reinforcement. Additionally, the cost of large-scale application of FR4 sheets could be prohibitive when compared to more traditional reinforcement materials like steel or carbon fiber-reinforced polymers (FRP) (Eurocircuits).

Conclusion

In synopsis, the outstanding properties of Epoxy Resin Sheets position them as exceptionally reasonable for a wide exhibit of modern applications; notwithstanding, their application as underlying support materials in development stays limited. The particular attributes of FR4 make it the most appropriate for conditions where electrical protection, warm dependability, and fire retardance are of essential significance, as opposed to for load-bearing purposes.

FR4's remarkable properties, including high mechanical strength, layered solidness, and fire opposition, highlight its importance in different modern areas, especially in electronic arrangements, aviation, car, and safeguard businesses. Its ability to endure natural stressors while keeping up with its shape and construction additionally improves its allure in these applications.

Contact Us

As a professional manufacturing supplier, we offer GMP-certified products with a large inventory, complete certifications, and support for OEM. We ensure fast delivery and secure packaging, accommodating testing requirements to facilitate global partnerships. For more details on our products and services, reach out to us at info@jhd-material.com, and let's explore how we can collaborate to meet your industrial needs.

For more in-depth information on the properties and applications of FR4 materials, you can refer to the detailed discussions available at Structure Magazine, MCL PCB, and Atlas Fibre.