Application of engineering plastics in weight reduction of electronic equipment

2022-11-15

1. Introduction

Radar electronic products are developing rapidly. In addition to their more and more functions and more advanced performance, their deadweight is becoming lighter and smaller. At this stage, military equipment mainly uses composite materials. The mechanical properties of the composite materials are excellent. The overall weight reduction can be achieved through structural optimization design or the use of low-density metal materials (such as aluminum alloy and magnesium alloy materials). However, for some small electronic equipment, the margin for structural optimization is limited. Considering the material itself, the replacement of engineering plastics with good performance and low density can also realize the lightweight of products.

The density of most engineering plastics is less than 2 g/cm3. Compared with aluminum products widely used today, the quality of products can be reduced by 50% by using engineering plastic products to process models with the same structure. More and more kinds of engineering plastics have been found, and some engineering plastics have excellent performance. Therefore, the research on the application and expansion of engineering plastics has gradually increased. This paper explores the application of engineering plastics in radar products, and uses the low density of engineering plastics to achieve lightweight products.

2. Application analysis of electronic equipment engineering plastics

The structural design of electronic equipment mainly improves the ability of the whole product to adapt to various working environments from the following four aspects. It is necessary to analyze the feasibility of replacing some metal materials with engineering plastics based on the structure and function of electronic equipment.

a) The electronic case is mainly used to install various electrical components and provide reliable mechanical structure strength and stiffness to ensure the normal operation of the whole product. The mechanical properties of engineering plastics are different due to their different forming methods and compositions, but they generally have high strength. The materials can be selected according to the specific use requirements. And aluminum alloy (2.7 × 103kg/m3), magnesium alloy (1.8 × 103kg/m3), most engineering plastics (1.2 × 103 kg/m3) has higher specific stiffness. Therefore, replacing metal materials with engineering plastics is an important way to reduce the weight of structures.

b) Structural members can improve the heat dissipation capacity of electrical equipment, control the temperature rise of components within the allowable range or ensure that components in the equipment can withstand the thermal shock of sudden temperature changes. The thermal conductivity, heat resistance and thermal expansion of engineering plastics are quite different from those of metal materials. The operating temperature of general electronic equipment is − 20 ° C 〜+85 ° C. Most common engineering plastics can be applied, for example, the thermal deformation temperature of polycarbonate is+127 ° C.

For electronic equipment, thermal conductivity is critical. The thermal conductivity of most engineering plastics is low, generally 0.14 〜 0.34 W/(m · K). At present, various researches on the thermal conductivity of engineering plastics are to form composite materials with high thermal conductivity by doping high thermal conductivity medium. Although the thermal conductivity of the composite has been improved hundreds of times, up to 20 〜 35 W/(m · K), there is still a big gap compared with the traditional metal heat dissipation materials (120 〜 250 W/(m · K)). Therefore, for high-density integrated radar electronic equipment, engineering plastics should not be used as heat conduction and heat transfer components.

c) The electronic case improves the ability of the whole equipment to resist harsh environment through structural design, and is applicable to various extreme environmental conditions. Most engineering plastics have good corrosion resistance to acid, alkali, salt and other media, and their electrochemical performance is superior to that of metal materials.

d) Structural design measures shall be taken for electronic equipment to minimize the electromagnetic interference from the external environment to the internal equipment and reduce the electromagnetic leakage of internal equipment to the external environment. Due to the electromagnetic shielding requirements, the chassis shell is generally made of metal materials to ensure the shell continuity and provide an internal electromagnetic shielding environment. Most engineering plastics are polymer materials, and their poor conductivity is the main reason that restricts their use in electronic equipment. Spraying conductive paint on the outer surface of engineering plastics to make its surface have a certain conductivity can play the role of shielding metal shield.

It can be seen from the analysis that engineering plastics can replace some materials of structural load-bearing parts of electronic equipment, and achieve electromagnetic shielding effect by coating conductive coating on its inner wall, thus reducing the weight of equipment.

3. Selection of engineering plastics

a) Processing technology

The material characteristics of different engineering plastics are different, and the corresponding processing technologies are also different. It is necessary to select appropriate processing and manufacturing methods according to the target materials, so as to give full play to the properties of materials. Common processing technology is shown in Table 1.

It can be seen from Table 1 that in the above molding processes, most processes require molds and complex processing tools. Therefore, small batches of products with complex structures at the radar design and development stage are not ideal processing methods.

NC machining belongs to traditional machining, which can be used for making simple parts. For complex structures, 3D printing technology can be used to realize the production of single or small batch of structural parts through the combination of numerical control processing and 3D printing.

Table 1 Common Processing Processes

Forming Process | mould | pressure | temperature |

Compression molding | Yes | Pressurization in the mold | Heating in mold |

injection molding | Yes | Pressurization in the mold | Heating in the appliance |

casting | Yes | / | / |

Dipping, coating and forming | Yes | / | Heating in mold |

3D printing technology | No | Nozzle pressurization | Nozzle heating |

CNC machining | No | Tool pressure | / |

b) Material Properties

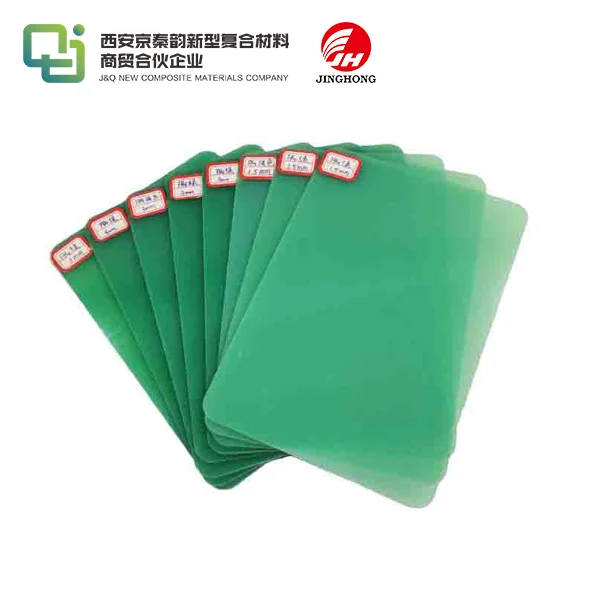

The processing method of 3D printing requires the selection of corresponding printing materials. When selecting materials for electronic products, materials with medium and high strength mechanical properties and high temperature resistance above 80 ℃ shall be selected. The selected materials are polycarbonate (PC), nylon (PA sheet), acrylonitrile butadiene styrene copolymer (ABS) and polyether ether ketone (PEEK). See Table 2 for specific performance parameters.

Table 2 Material Performance Parameters

Performance | PC | ABS | PEEK | PA |

Maximum tensile strength/MPa | 57.0 | 32.0 | 93.5 | 48.0 |

Tensile elongation at break/% | 4.80 | 7.00 | 7.45 | 18.00 |

Maximum bending strength/MPa | 69 | 60 | 145 | 50 |

Thermal deformation temperature/° C | 138 | 96 | 147 | 100 |

Coefficient of thermal expansion( × 10−5)/◦C−1 | 3.800 | 8.820 | 5.314 | 3.600 |

Density/(g · cm − 3) | 1.20 | 1.04 | 1.28 | 1.00 |

For 3D printing, the costs of different materials are different. PEEK with the best performance has the highest price, while PC, ABS and PA have moderate prices. From the perspective of material performance and economy, PC and PA materials can not only ensure strength, but also maintain stability at high temperatures. They are materials that meet the basic use needs of the radar industry, and are cheap. They are suitable for small batches and various kinds of processing replacement parts.

4. Weight reduction design of an industrial molding case

As a portable equipment, the original design material of an industrial molding case is 6063 aluminum alloy. The whole machine is heavy, which is not conducive to the operation and use of personnel. Therefore, weight reduction design is required.

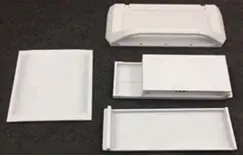

a) Chassis structure

The chassis adopts 3U closed cooling conduction design, which is mainly composed of upper and lower cooling plates, front and rear panels, partition frames, side plates and fan mounting plates. The heat is transmitted from the cooling guide plate to the upper and lower cooling plates, and then the heat is discharged by the secondary air cooling through the cooling teeth of the upper and lower cooling plates of the chassis. A closed structure is formed inside the case to ensure the environmental adaptability and electromagnetic shielding performance of the whole machine.

b) Weight reduction design

For heat dissipation, the upper and lower cooling plates of the chassis still need to be made of metal materials with good thermal conductivity. Compared with 6063 series aluminum alloy of the original chassis, the cold plate is made of magnesium alloy with high thermal conductivity. The remaining parts (such as the front panel, side panel and other non heat transfer structures) are mainly used to form the enclosure of the chassis, and some electrical parts can be installed at the same time. Engineering plastics with lower density can be used. This time, PC and PA materials are used to replace them.

Except for the heat conduction structure, other structural members of the chassis are made of engineering plastics. In order to ensure the electromagnetic shielding performance of the chassis, conductive paint shall be applied on the internal surface of the structural members. Silver paste or nickel conductive paint is selected as the spraying material for the inner surface of the structural members.

PC or PA materials have excellent processing performance. After printing, various installation interfaces of parts (such as threaded holes, steel wire thread insert holes, etc.) can be post processed to ensure the assembly accuracy of the chassis. The printed product is shown in Figure 3.

Finally, the thread processing test is carried out. For 3D printing structural parts, due to the restriction of processing mechanism, there are a lot of gaps inside, and the post processed steel wire thread sleeve will fall off and crack after installation, as shown in Figure 4. In order to solve this problem, the NC machining method of profiles is used to make parts with threads. For this equipment, the plates on both sides are replaced with profiles PA for direct processing, and steel wire inserts are installed. Through physical verification, the threaded sleeve is installed tightly without falling off.

c) Mechanical analysis

The replaced parts are front panel, rear cover plate, side plate, fan mounting plate and split frame. The impact check is mainly conducted for the characteristics of poor ductility of materials. The calculation condition is that the gravity acceleration in X direction and Y direction is 9 g respectively, and the gravity acceleration in Z direction is 14 g, and the time is 11 ms.

From the mechanical simulation results, it can be seen that the maximum stress is 8.42 MPa after the chassis is loaded with impact load in three directions, and the material strength is 1.5 times of the safety factor, which is less than the strength of nylon material 32 MPa, meeting the use requirements.

d) Thermal analysis

The chassis mainly contains five boards, with a total power consumption of 60.2 W. The thermal design index is the maximum ambient temperature of 55 ° C, the shell temperature of electronic devices is lower than 85 ° C, and the side wall temperature of the chassis is lower than 75 ° C. The maximum temperature of the side wall of the chassis is 71.4 ° C, and the maximum temperature of the board components is 82 ° C, which appears on the storage board and meets the design requirements.

e) Summary

The main heat dissipation material of the chassis is magnesium alloy with high thermal conductivity instead of the original aluminum alloy material. The rest of the structural parts are changed to engineering plastic Nylon 6 sheet, and the mass of each part is calculated, as shown in Table 4. On the premise of meeting all indicators, the total weight of the chassis structure is reduced by 45.3%, which shows that the weight reduction effect of engineering plastics and light magnesium alloy is very obvious. The whole frame weighs about 2 kg, meeting the lifting needs of personnel, and saving the quality index of the carrier platform.

Material | Total mass/g | Cost/yuan |

Aluminium alloy | 3691 | 20000 |

Magnesium alloy | 2461 | 25100 |

PA | 1931 | 14000 |

From the point of view of mechanics and thermodynamics, the simulation and experiment of the case which replaced PC material and PA material were carried out. The conductive paint adopts silver paste, which not only ensures the electromagnetic shielding performance of the chassis, but also improves the three proofing performance of the structure.

For plastic products, it is also necessary to test their light aging characteristics through light aging experiments to verify the service life of their materials under different spectra.

5. Conclusion

Engineering plastics are widely used in civil fields such as electronic appliances, automobiles and buildings due to their excellent comprehensive properties. With the continuous miniaturization of electronic equipment, engineering plastics have broad prospects in the field of military electronic equipment. For case type electronic equipment, engineering plastics can be used at appropriate positions to replace metal materials, so as to improve the power efficiency of the whole system, and optimize and simplify the manufacturing and assembly process of important parts.

In the application of engineering plastics, it is necessary to fully understand the physical, chemical, mechanical and other properties of materials, and combine with more mature coating and manufacturing methods to carry out effective weight reduction optimization design. For single piece and small batch products, 3D printing costs are low. However, due to the forming principle, it is difficult to obtain structural parts with dense materials similar to metal, which have internal pores and local structural strength is insufficient; For large quantities of products, injection molding can ensure the formation of quality tight structural parts. Therefore, when applying engineering plastics, it is necessary to combine cost and performance factors and comprehensively consider processing methods.