Can a Flame Resistance FR4 Fiber Glass Laminate Sheet be used for aerospace applications?

2024-06-13 16:02:15

1. Understanding FR4 Fiber Glass Laminate Sheets

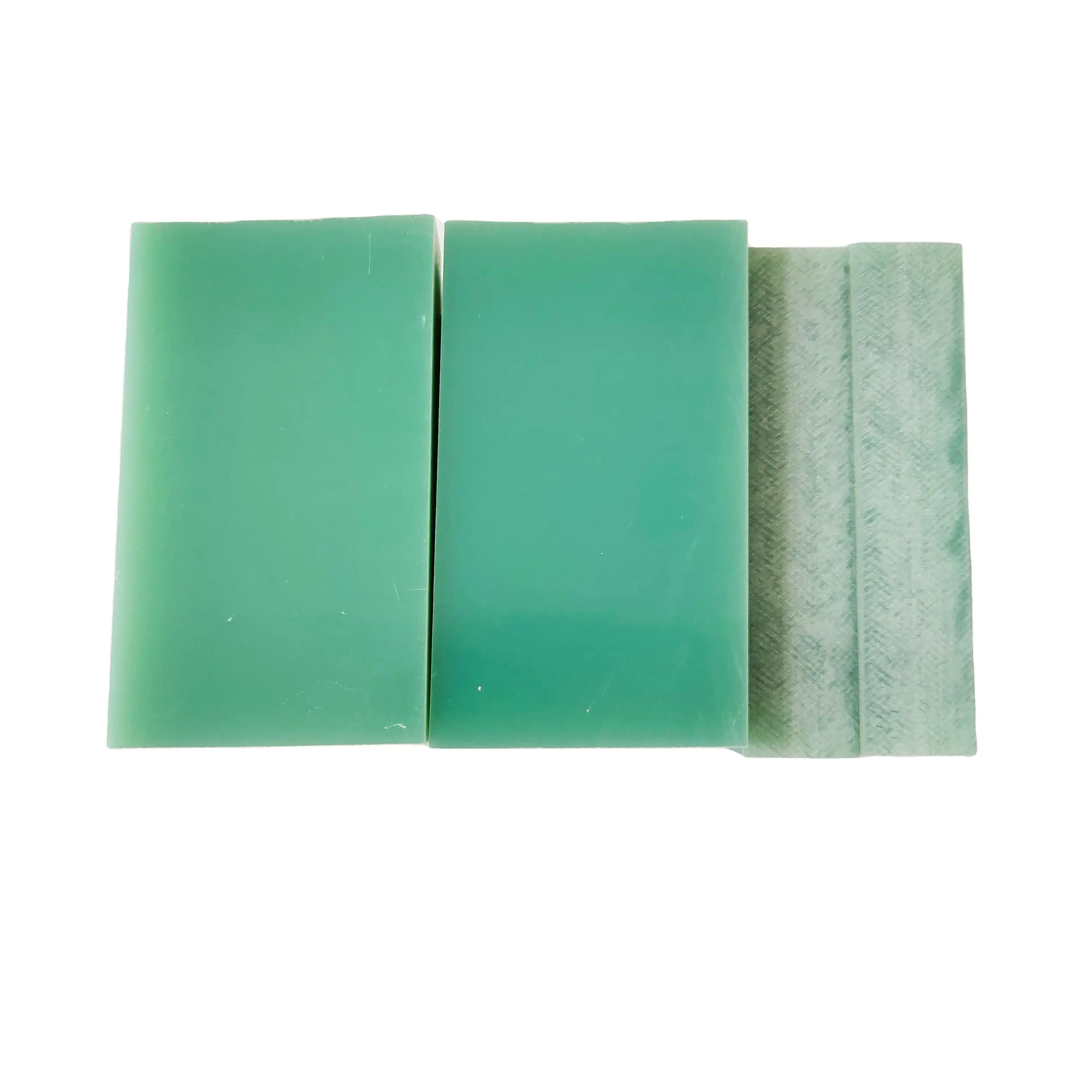

FR4 (Flame Retardant 4) is a type of fiberglass-reinforced epoxy laminate that possesses excellent electrical insulation properties, mechanical strength, and flame resistance. It is commonly used in various industries such as electronics, automotive, and telecommunications for its versatility and reliability. FR4 sheets are composed of woven fiberglass cloth impregnated with epoxy resin, which is then cured under high temperature and pressure to form a solid, durable material.

2. Properties of FR4 Fiber Glass Laminate Sheets

Flame Resistance FR4 Fiber Glass Laminate Sheets exhibit several key properties that make them suitable for a wide range of applications. Firstly, they offer high mechanical strength and dimensional stability, making them ideal for applications where durability and reliability are crucial. Additionally, FR4 sheets have excellent electrical insulation properties, with high dielectric strength and low electrical conductivity, making them suitable for use in electrical and electronic components. Moreover, FR4 laminate sheets are flame resistant, meaning they have the ability to self-extinguish when exposed to flames, which is essential for safety in many applications.

3. Aerospace Applications and Requirements

The aerospace industry demands materials that can withstand extreme conditions and rigorous performance requirements. From commercial aircraft to space exploration vehicles, every component must meet strict standards for safety, reliability, and performance. When considering the use of FR4 fiber glass laminate sheets in aerospace applications, several factors need to be taken into account. These include temperature resistance, mechanical strength, electrical insulation, and compatibility with other materials used in aerospace construction.

The aerospace industry is characterized by its stringent requirements for materials that can withstand the rigors of space travel, including extreme temperature fluctuations, micrometeoroid impacts, and high radiation levels.Flame Resistance FR4 Fiber Glass Laminate Sheets, with their excellent temperature resistance and mechanical strength, are potential materials for use in aerospace applications. However, their performance must be evaluated under conditions that simulate the space environment to ensure they can maintain their properties without degradation over long durations of exposure.

Furthermore, the electrical insulation properties of FR4 are critical in aerospace applications where electronic systems control vital functions of the spacecraft. The material must guarantee reliable insulation to prevent electrical shorts or failures that could compromise the mission. Additionally, the compatibility of FR4 with other aerospace materials, such as metal alloys and composites, must be thoroughly tested to avoid issues like thermal expansion mismatch or chemical incompatibility, which could lead to delamination or structural failures.

In summary, while FR4 fiber glass laminate sheets exhibit promising characteristics for use in aerospace applications, they must undergo rigorous testing and validation to meet the industry's specific requirements for safety, reliability, and performance in the unique challenges presented by space environments.

4. Suitability of FR4 Fiber Glass Laminate Sheets for Aerospace

While FR4 laminate sheets offer many desirable properties, their suitability for aerospace applications depends on specific requirements and regulations. In certain cases, FR4 may be suitable for non-critical components such as interior panels, insulation barriers, or structural reinforcements where flame resistance and electrical insulation are important. However, for critical components such as avionics, control systems, or structural elements, aerospace manufacturers may prefer materials that offer higher temperature resistance, lower weight, or superior mechanical properties.

Moreover, aerospace applications often require materials to conform to stringent industry standards such as ASTM (American Society for Testing and Materials) and NASA (National Aeronautics and Space Administration) specifications. These standards ensure that the materials can withstand the extreme conditions of space travel, including variations in pressure, temperature, and radiation levels. FR4 fiber glass laminate sheets must undergo rigorous testing to meet these standards and prove their reliability in such environments.

In summary, while Flame Resistance FR4 Fiber Glass Laminate Sheets have potential uses in aerospace due to their flame resistance and electrical insulation properties, they may not be suitable for all applications within this sector. The decision to use FR4 should be based on a comprehensive assessment of the material's properties in relation to the specific requirements and regulations governing aerospace materials. Manufacturers must carefully consider the performance demands of each component and select materials that will ensure the safety, reliability, and functionality of their aerospace systems.

5. Conclusion and Considerations

In conclusion, the use of FR4 fiber glass laminate sheets in aerospace applications depends on a variety of factors including specific requirements, regulations, and performance criteria. While FR4 offers excellent flame resistance, electrical insulation, and mechanical strength, its suitability for aerospace use may vary depending on the application and the level of performance required. Aerospace manufacturers should carefully evaluate the properties and characteristics of FR4 laminate sheets in relation to their specific needs before incorporating them into their designs.

Contact Us

For professional manufacturing of Flame Resistance FR4 Fiber Glass Laminate Sheets and other composite materials, contact us at info@jhd-material.com. We are a GMP factory with a large inventory, complete certificates, and support OEM. Our fast delivery and tight packaging ensure that your materials arrive on time and in perfect condition. Partner with us and join our global network of satisfied buyers.

References

1. "FR-4 - Wikipedia." https://en.wikipedia.org/wiki/FR-4. Accessed 17 May 2024.

2. "Aircraft Materials - FR4." https://www.aircraftmaterials.com/data/composites/composites-fr4.html. Accessed 17 May 2024.

3. "FR-4 Glass/Epoxy Laminate Material - 3k.com." https://www.3k.com/FR4-Glass-Epoxy-Laminate-Material.aspx. Accessed 17 May 2024.

4. "Aerospace Materials - AZoM." https://www.azom.com/materials-search.aspx?cat=14. Accessed 17 May 2024.