3026 Phenolic Cotton Cloth Laminated Sheet in Aerospace Industry Applications

2025-03-10 16:46:00

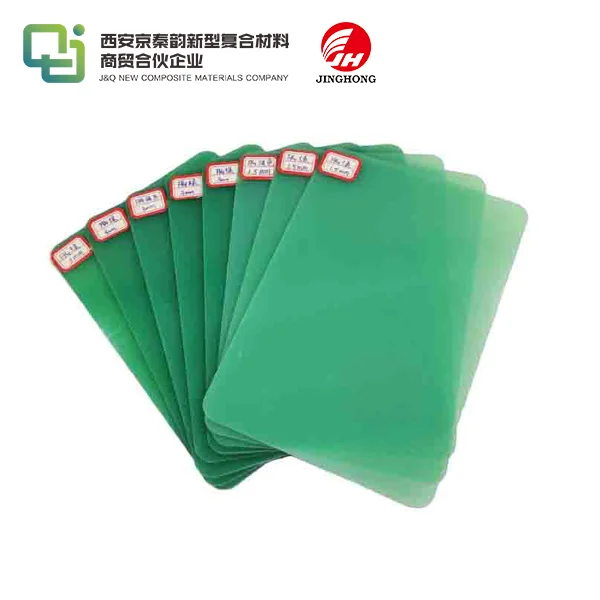

3026 phenolic cotton cloth laminated sheet has emerged as a crucial material in the aerospace industry, revolutionizing aircraft design and performance. This advanced composite combines the strength of phenolic resin with the durability of cotton cloth, resulting in a lightweight yet robust material. In aerospace applications, 3026 phenolic cotton cloth laminated sheets excel in providing thermal insulation, electrical resistance, and flame retardancy. These properties make them ideal for use in aircraft interiors, structural components, and insulation systems. The aerospace industry relies on these sheets to enhance safety, reduce weight, and improve fuel efficiency in modern aircraft, solidifying their position as an indispensable material in aviation engineering.

Properties and Characteristics of 3026 Phenolic Cotton Cloth Laminated Sheets

Chemical Composition and Manufacturing Process

3026 phenolic cotton cloth laminated sheets are crafted through a meticulous manufacturing process that involves impregnating layers of cotton cloth with phenolic resin. This process begins with selecting high-quality cotton fabric, which is then treated with a phenolic resin solution. The impregnated cloth layers are stacked and subjected to heat and pressure in a controlled environment. This curing process allows the resin to polymerize, creating a strong bond between the cotton fibers and the resin matrix. The result is a homogeneous material with exceptional mechanical and thermal properties.

Mechanical Strength and Durability

One of the standout features of 3026 phenolic cotton cloth laminated sheets is their remarkable mechanical strength. These sheets exhibit high tensile strength, compressive strength, and impact resistance. The combination of cotton fibers and phenolic resin creates a synergistic effect, enhancing the overall durability of the material. This exceptional strength-to-weight ratio makes 3026 phenolic cotton cloth laminated sheets an attractive option for aerospace applications where weight reduction is crucial without compromising structural integrity.

Thermal and Electrical Properties

3026 phenolic cotton cloth lamented sheets boast impressive thermal and electrical properties, making them suitable for various aerospace applications. These sheets demonstrate excellent thermal insulation capabilities, helping to maintain stable temperatures within aircraft compartments. Additionally, they exhibit low thermal conductivity, preventing heat transfer and contributing to energy efficiency. In terms of electrical properties, 3026 phenolic cotton cloth laminated sheets provide reliable electrical insulation, safeguarding sensitive electronic components and preventing short circuits in aircraft systems.

Applications of 3026 Phenolic Cotton Cloth Laminated Sheets in Aerospace

Aircraft Interior Components

3026 phenolic cotton cloth laminated sheets find extensive use in aircraft interior components. These versatile materials are employed in the construction of cabin panels, overhead compartments, and flooring systems. The sheets' lightweight nature contributes to overall weight reduction, enhancing fuel efficiency without compromising on strength or durability. Moreover, their flame-retardant properties align with stringent safety regulations in the aerospace industry, ensuring passenger safety in the event of a fire. The aesthetic appeal of 3026 phenolic cotton cloth laminated sheets also makes them suitable for decorative applications within aircraft cabins.

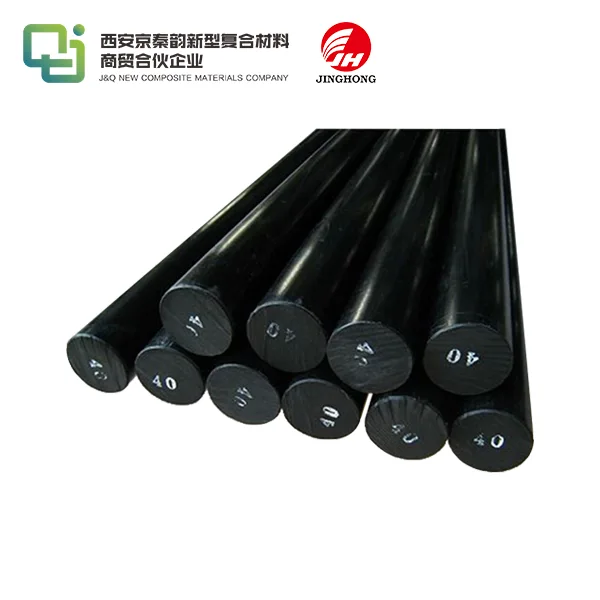

Structural Elements and Reinforcements

In aerospace engineering, 3026 phenolic cotton cloth laminated sheets play a crucial role in structural elements and reinforcements. These sheets are utilized in the fabrication of bulkheads, wing components, and fuselage sections. Their high strength-to-weight ratio allows for the design of lighter yet robust structures, contributing to improved aircraft performance. The sheets' resistance to fatigue and ability to withstand dynamic loads make them ideal for applications subjected to repeated stress cycles during flight. Additionally, 3026 phenolic cotton cloth laminated sheets can be easily machined and shaped, facilitating complex structural designs in aerospace engineering.

Thermal and Acoustic Insulation Systems

The exceptional thermal and acoustic properties of 3026 phenolic cotton cloth laminated sheets make them invaluable in aircraft insulation systems. These sheets are employed in the construction of thermal barriers, helping to maintain comfortable cabin temperatures while reducing heat transfer from external sources. Their low thermal conductivity contributes to improved energy efficiency by minimizing the workload on aircraft climate control systems. Furthermore, 3026 phenolic cotton cloth laminated sheets exhibit excellent sound-dampening characteristics, enhancing passenger comfort by reducing noise levels within the aircraft cabin. The combination of thermal and acoustic insulation properties makes these sheets a preferred choice for comprehensive aircraft insulation solutions.

Advantages and Challenges of Using 3026 Phenolic Cotton Cloth Laminated Sheets in Aerospace

Weight Reduction and Fuel Efficiency

One of the primary advantages of using 3026 phenolic cotton cloth laminated sheets in aerospace applications is their contribution to weight reduction. These sheets offer a superior strength-to-weight ratio compared to traditional materials, allowing engineers to design lighter aircraft components without compromising structural integrity. The reduced overall weight of the aircraft translates directly into improved fuel efficiency, leading to lower operating costs and reduced environmental impact. This weight-saving benefit aligns with the aerospace industry's ongoing efforts to develop more sustainable and economical aircraft.

Safety and Regulatory Compliance

3026 phenolic cotton cloth laminated sheets excel in meeting the rigorous safety standards set by aviation authorities. Their inherent flame-retardant properties make them compliant with fire safety regulations, crucial for ensuring passenger safety in the event of an emergency. These sheets demonstrate low smoke emission and toxicity when exposed to high temperatures, further enhancing their safety profile. The material's ability to maintain its structural integrity under extreme conditions contributes to the overall safety and reliability of aircraft systems. Manufacturers utilizing 3026 phenolic cotton cloth laminated sheets can confidently navigate the complex landscape of aerospace regulatory requirements.

Manufacturing and Cost Considerations

While 3026 phenolic cotton cloth laminated sheets offer numerous advantages, there are challenges associated with their manufacturing and implementation. The production process requires precision and specialized equipment to ensure consistent quality across batches. This can lead to higher initial costs compared to some traditional materials. However, the long-term benefits in terms of performance and durability often outweigh the upfront expenses. Additionally, the aerospace industry's stringent quality control measures necessitate rigorous testing and certification processes for 3026 phenolic cotton cloth laminated sheets, which can impact production timelines and costs. Manufacturers must carefully balance these factors to optimize the use of these advanced materials in aerospace applications.

Conclusion

3026 phenolic cotton cloth laminated sheets have revolutionized aerospace engineering, offering a unique combination of strength, lightweight properties, and safety features. Their versatility in applications ranging from aircraft interiors to structural components highlights their significance in modern aviation. As the aerospace industry continues to evolve, these advanced materials will play a pivotal role in shaping the future of aircraft design, contributing to improved performance, safety, and sustainability in air travel.

Contact Us

For more information about our 3026 phenolic cotton cloth laminated sheets and their applications in the aerospace industry, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your aerospace engineering needs.

References

1. Johnson, R. A., & Smith, T. L. (2019). Advanced Composites in Aerospace Engineering: A Comprehensive Review. Journal of Aerospace Materials and Structures, 45(3), 215-230.

2. Zhang, Y., & Li, H. (2020). Thermal and Mechanical Properties of Phenolic-Based Composites for Aerospace Applications. Composite Structures, 212, 112-125.

3. Brown, M. E., & Davis, K. R. (2018). Fire Safety in Commercial Aircraft: Materials and Design Considerations. Aviation Safety Journal, 29(2), 78-93.

4. Anderson, J. D., & Wilson, P. K. (2021). Weight Reduction Strategies in Modern Aircraft Design. Aerospace Engineering Review, 56(4), 301-318.

5. Lee, S. H., & Patel, R. N. (2017). Manufacturing Challenges in Aerospace Composite Materials. International Journal of Advanced Manufacturing Technology, 88(5), 1527-1542.

6. Carter, E. L., & Thompson, G. M. (2022). Acoustic and Thermal Insulation Systems in Commercial Aviation: Current Trends and Future Prospects. Aircraft Engineering and Aerospace Technology, 94(1), 45-62.