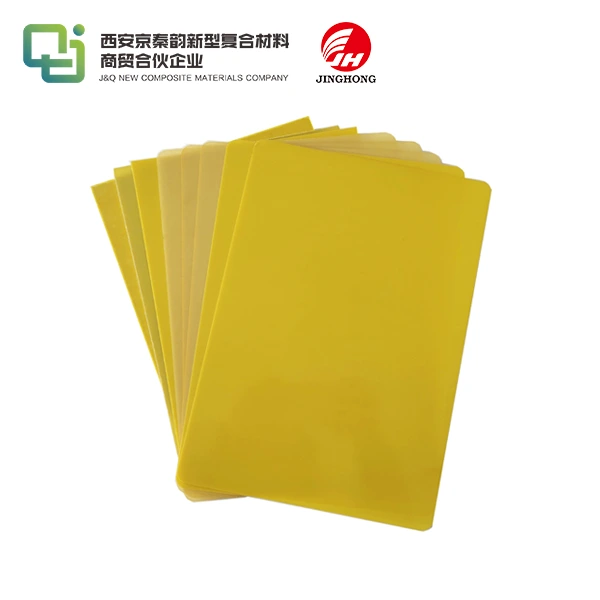

3240 Epoxy Fiberglass Sheet

Brand: Hongda

Materials: Epoxy Resin, Phenolic Resin

Nature Color: Yellow

Thickness: 0.3mm --- 100mm

Size: 1020mm*2020mm (Regular)

Packaging: Regular packing, Protect by Pallet

Productivity: 13000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

3240 epoxy fiberglass sheet is made of alkali-free glass fiber cloth impregnated with epoxy phenolic resin, baked and hot pressed. It has high mechanical, dielectric properties, good heat resistance and moisture resistance. 3240 epoxy fiberglass sheet has high mechanical strength at medium temperature, and good electrical performance stability under high humidity. The surface of the board is required to be smooth, free of bubbles, no pits and wrinkles.

As the price of 3240-B is cheaper than 3240-A and has good practicability, it is more common in the market. For more information, please kindly contact our sellers.

Application

3240 epoxy fiberglass sheet is used in machinery, electric appliance and electronic high insulation components, also, it is suitable for motors and electrical equipment as an insulation parts and can be used in humid environments and transformer oil.

The Main Application of 3240 Epoxy Fiberglass Sheet:

● Chemical machinery parts, General machinery parts

● Gear, Generators, Pads, Bases, Baffles, Transformer, Fixture Invertor, Motor, Electric Insulation Component

● Fixture Board, the Mold Plate, High and Low Voltages Distribution Box

● PCB, ICT Fixture, Molding Machine, Drilling Machine, Mesa Grinding Pads

1. Test Jig

2. Fixture PCB Testing Jig

3. Insulation Plate

4. Switch insulation Plate

5. Polish Gear

6. Mould in Cloth and Shoes

7. Insulation Part of Bakelite Sheet

8. Lithium Battery Pack

Technical Data for 3240 GradeB

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

|

1 |

Density |

g/cm3 |

2.07 |

GB/T 1303.2-2009 |

|

|

2 |

Water Absorption |

mg |

6.0 |

||

|

3 |

Bending Strength Perpendicular to Laminations |

A |

MPa |

203 |

|

|

B |

192 |

||||

|

4 |

Modulus of Elasticity in Flexure |

A |

MPa |

2.12*104 |

|

|

B |

2.38*104 |

||||

|

5 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

A |

KJ/m² |

47.4 |

|

|

B |

35.8 |

||||

|

6 |

Parallel Layer Shear Strength |

A |

MPa |

49.8 |

|

|

B |

52.7 |

||||

|

7 |

Tensile Strength |

A |

MPa |

147 |

|

|

B |

121 |

||||

|

8 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

438 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.0*109 |

||

|

10 |

Vertical Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

MV/m |

8.6 |

||

|

11 |

Parallel Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

kV |

28.0 |

||

|

12 |

Flammability |

- |

V-1 |

||

|

13 |

Deflection Temperature under Load |

A |

℃ |

>140 |

|

|

B |

>140 |

||||

|

14 |

Adhesive Strength |

N |

6324 |

GB/T 1303.6-2009 |

|

|

REMARK: 1. NO.2 the sample size is 50mm*50mm*50mm; 2. NO.8 the sample height is (9.05~9.56) mm; 3. NO.10 the sample thickness is (2.91~2.95)mm; 4. NO.11 the sample size is 100.00mm*5.08mm*24.10mm; |

|||||

Production Process

Factory

J&Q New Composite Materials Company is a foreign trade company controlled by Hebei JingHong Electronic Technology Co., Ltd., which is responsible for the export business of Hebei JingHong Electronic Technology Co., Ltd. The new factory of Hebei JingHong Electronics Co., Ltd. will be officially put into production in October 2022. Mainly produce FR4 sheet, 3240 epoxy sheet, Bakelite sheet, and 3026 phenolic cotton sheet. The total annual output of the new and old two factories reaches 43,000 tons, which will be the largest insulation board factory in China.

One of our greatest advantage is the orders which are directly from us has the priority to produce first. Also, we have our own logistics company, so it can provide safe and fast service to you. What we are trying to do is providing our customers one-stop service from production to delivery.

Our strength

1. The annual production capacity of the factory is 43,000 tons, which is one of the largest insulation board manufacturers in China

2. Fully automated production workshop, product quality is stable

3. We have more than 20 years of experience in producing and selling insulating sheet, Cooperate with a number of domestic and foreign trading companies for many years.

4. Professional foreign trade team can provide perfect services

5. Have our own logistics company, provide one-stop service

Packaging and Shipping

Regular packing, Protect by Pallet

Send Inquiry