What Is the Use of Bakelite Sheet?

2024-07-23 15:26:15

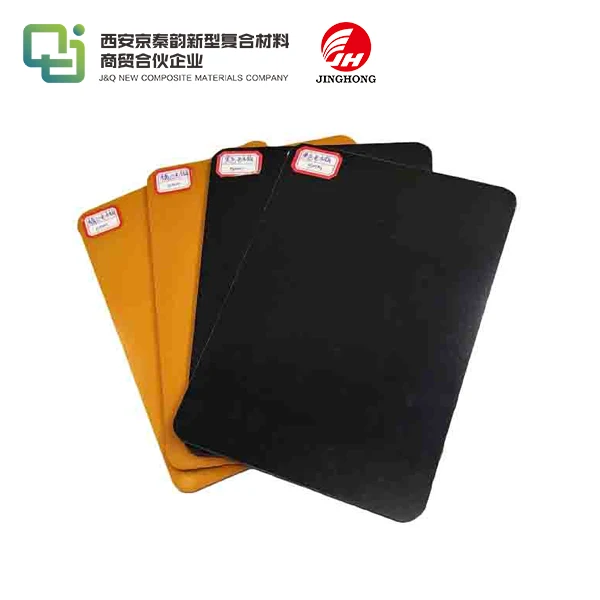

Because of their distinctive features and versatility, Bakelite sheets have long been prized and are now a vital part of many different industries.Because of its exceptional mechanical strength, superior insulating qualities, and resilience to heat and chemicals, sheets are used in many different industries. This blog discusses the main uses, advantages, and worth of sheets in modern applications.

How Are Bakelite sheets Used in Electrical Insulation?

Due to their well-known superior electrical insulating properties, Bakelite sheets are essential in the electrical and electronic industries. When one is familiar with how sheets are used as electrical insulation, it is simpler to comprehend how they can improve performance and safety in a variety of applications.

Insulating Electrical Components with sheets sheets serve as a barrier that prevents electrical currents from escaping and resulting in shocks or short circuits. When it comes to safeguarding electrical systems, this insulation plays a crucial role.

Electrical Panels and Switchboards The construction of electrical panels and switchboards makes use of sheets. They keep electrical connections safe and contained because they are insulators. As a result, the system as a whole is safer and short circuits are less likely to occur. These panels, which frequently have to withstand high voltages, require Bakelite's high dielectric strength.

An electronic circuit's stable and non-conductive platform is provided by bakelite, which is used as a base material in circuit boards. Due to its ability to withstand high temperatures without deteriorating, it is ideal for use in printed circuit boards (PCBs), which require materials that maintain performance under varying thermal conditions.

Electrical Insulators sheets are used to make a variety of electrical insulators that keep unwanted current from flowing through conductive parts and separate conductive components. This application is necessary for systems and devices that operate at high voltages and require dependable insulation.

Insulation for Transformers sheets cover transformer coils and other components to prevent short circuits and keep electrical currents moving in the right direction. Due to the fact that transformers can generate a significant amount of heat when running, bakelite's thermal resistance is also crucial in this circumstance.

Busbars and Connectors sheets typically act as busbar and connector isolation. These parts need to be able to handle high electrical loads because bakelite's insulating properties prevent electrical leakage and improve operational safety.

Benefits of Bakelite in Electrical Applications Because of their numerous benefits, sheets are a popular choice for electrical insulation.

Due to its capacity to withstand high voltages without breaking down, High Dielectric Strength Bakelite is suitable for use in high-voltage applications where other materials might fail.

Thermal Stability Bakelite's ability to maintain its properties even at high temperatures ensures dependable performance even in environments where temperatures fluctuate frequently. As a result, it is an excellent choice for use in components that produce a lot of heat.

Mechanical Stability Bakelite's mechanical strength ensures that it will not degrade when subjected to physical stress. This durability is necessary for preserving the integrity of electrical components over time.

What Are the Industrial Applications of Bakelite sheet

Bakelite sheets are extensively utilized in numerous industrial applications in addition to their use as electrical insulation. They are suitable for a wide range of industrial applications due to their mechanical strength, chemical resistance, and thermal stability.

Due to their durability and strength, sheets are used to make a wide range of equipment and gear components.

Bearing and Wear Plates sheets serve as bearing and wear plates for modern equipment. Because they resist wear and mechanical pressure, they are ideal for applications where parts are frequently developed and ground.

Gears and Pulleys sheets are an alternative for light but durable gears and pulleys. While still maintaining the strength and wear resistance necessary for smooth operation, they reduce the machinery's overall weight.

sheets can be used in environments where corrosive substances are frequently encountered due to their resistance to chemicals and corrosion.

sheets are utilized in the construction of equipment for chemical processing due to their durability and resistance to acids, bases, and solvents. The pharmaceutical, petrochemical, and food processing industries all make extensive use of this application.

Equipment and Benchtops in the Laboratory sheets are utilized for benchtops and equipment in the laboratory. Since they are synthetic safe, they can endure compound openness and spills without disintegrating.

Thermal Insulation Bakelite is an excellent material for industrial thermal insulation due to its thermal stability.

sheets are used as insulation in ovens and furnaces due to their resistance to melting at high temperatures. Ceramics and metalworking are two industries that make frequent use of this application.

Heat Shields and Barriers sheets are used as heat shields and barriers in industrial settings where effective heat management is required. They are excellent thermal insulators, preventing heat damage to other parts because they can withstand high temperatures.

sheets can be tailored to specific modern applications, resulting in customized arrangements that meet specific requirements.

sheets Can Be Machined Into A Wide Variety of Parts and Components This customization enables the production of parts that precisely meet the requirements for performance and specifications. sheets Can Be Machined Into A Wide Variety of Parts and Components

sheets are used to create models and prototypes during product development and prototyping. They are ideal for testing and development due to their durability and ease of machining.

How Are Bakelite sheets Used in Consumer Products?

Bakelite sheets have also been used for a long time to make consumer goods. Because of their unique properties, they can be used in a wide range of everyday items.

Due to their durability and aesthetic appeal, sheets are utilized in a variety of household items.

Due to its heat resistance and insulation properties, bakelite is ideal for kitchenware and utensils. It is used to make handles for pots, pans, and electrical appliances like toasters and mixers.

sheets are used to finish furniture and other decorative items' surfaces and make decorative laminates. Due to their durability, heat resistance, and chemical resistance, they are suitable for tabletops, cabinetry, and other furniture components.

Consumer electronics have relied heavily on sheets, which provide insulation and durability.

Casings for Radios and Telephones Previously, Bakelite was frequently utilized in radio and telephone casings. Its ability to be molded into a variety of shapes made it possible to create designs that were both stylish and useful, and its insulation protected the internal components.

Modern Electronics Despite the fact that plastics and other materials now make up the majority of modern electronic devices, Bakelite is still used in some applications where its properties are advantageous, like in high-heat or high-insulation components.

Due to their durability, strength, and resistance to heat and chemicals, sheets are utilized in a variety of automotive components.

Dashboards and Other Interior Vehicle Parts Bakelite is a heat-resistant, long-lasting material that is used to extend the life and performance of interior vehicle parts like dashboards.

Electrical Systems sheets ensure the safety and dependability of automobile electrical systems by providing insulation and protection for wiring and electrical components.

Benefits in Consumer Goods There are a number of benefits to using sheets in consumer goods that help keep them relevant.

Due to its mechanical strength and wear resistance, bakelite products are guaranteed to last for a long time. They don't need to be replaced as frequently because of their long lifespan, which saves money and makes them easier for customers to use.

Products will continue to perform and look good over time in environments that are frequently exposed to heat and chemicals due to Bakelite's resistance to heat and chemicals.

Versatility in Use and Appearance Bakelite can be shaped and finished in a wide range of ways, allowing for a wide range of applications. As a result, products that are both visually appealing and highly functional can be made.

Conclusion

Bakelite sheets remain a vital material in various applications due to their unique properties, including excellent electrical and thermal insulation, mechanical strength, and chemical resistance. From electrical components and industrial machinery to consumer products, Bakelite's versatility and reliability make it a preferred choice in many fields. Its continued use and relevance highlight the enduring value of sheets in modern applications.

References

1. The History and Uses of Bakelite. (n.d.). Retrieved from [Science History Institute](https://www.sciencehistory.org/historical-profile/leo-hendrik-baekeland-and-bakelite)

2. Bakelite: The Material That Changed the World. (2023). Retrieved from [American Chemical Society](https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/bakelite.html)

3. Applications of Bakelite sheets. (2022). Retrieved from [ResearchGate](https://www.researchgate.net/publication/322658616_Applications_of_Bakelite_Sheets)

4. Phenolic Resins in Industrial Applications. (2021). Retrieved from [Construction Specifier](https://www.constructionspecifier.com/phenolic-resins-in-industrial-applications/)

5. The Versatility of Bakelite in Modern Manufacturing. (2020). Retrieved from [Industry Week](https://www.industryweek.com/technology-and-iiot/the-versatility-of-bakelite-in-modern-manufacturing)