What is FR4 commonly used in?

2024-08-09 13:57:42

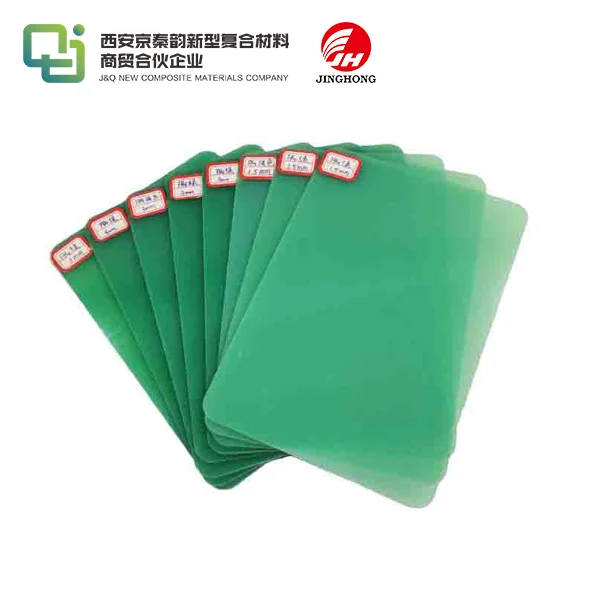

When it comes to versatile materials in the electronics industry, FR4 stands out as a true workhorse. This flame-resistant, glass-reinforced epoxy laminate has become an indispensable component in numerous applications. But what exactly is FR4, and where do we commonly find it? Let's dive into the world of FR4 sheets and explore their widespread use across various industries.

Understanding FR4: The Backbone of Printed Circuit Boards

FR4, short for Flame Retardant 4, is a composite material made from woven fiberglass cloth with an epoxy resin binder. Its name comes from its flame-resistant properties, making it an ideal choice for applications where fire safety is crucial. The FR4 sheet is known for its excellent electrical insulation properties, high strength-to-weight ratio, and remarkable durability.

One of the most common uses of FR4 is in the production of printed circuit boards (PCBs). These boards form the foundation of nearly all electronic devices we use daily. From smartphones to computers, televisions to automotive electronics, FR4-based PCBs are everywhere. The material's stability across a wide range of temperatures and its ability to maintain its electrical properties make it perfect for this application.

Beyond PCBs: Diverse Applications of FR4 Sheets

While PCBs might be the star of the show, FR4 sheets have found their way into numerous other applications:

Aerospace and Aviation

In the aerospace and aviation industries, the unique properties of FR4 make it an excellent material choice. Its lightweight nature combined with high strength is crucial for reducing the weight of aircraft components without sacrificing durability. FR4 sheets are commonly used in manufacturing aircraft instrument panels, circuit boards for avionics systems, and other critical components where precision and reliability are paramount.

Industrial Equipment

FR4's robust resistance to heat and chemicals makes it a valuable material for industrial machinery and equipment. It is often utilized in insulation applications, protecting sensitive electronic components from heat and electrical interference. Additionally, FR4's structural strength enables its use in various machine parts and housings, ensuring longevity and performance under harsh industrial conditions.

Automotive Industry

The automotive sector benefits from FR4's versatility in several ways. It is used extensively in automotive electronics, including dashboard displays, engine control units, and various sensors. FR4's electrical insulation properties are crucial for ensuring the reliability and safety of automotive electronic systems.

Telecommunications

In telecommunications, FR4 sheets play a key role in ensuring the reliable operation of communication equipment. Components such as cell phone towers, network switches, and signal amplifiers often incorporate FR4 due to its excellent electrical insulation and durability.

Medical Devices

FR4's reliability and biocompatibility make it a suitable material for certain medical devices and equipment. It is used in the manufacturing of components that require both electrical insulation and durability, such as diagnostic equipment and monitoring devices. The material's ability to maintain performance in varied conditions supports the functionality and safety of medical devices, contributing to improved patient care.

Renewable Energy

The renewable energy sector also benefits from FR4's properties. Solar panels and wind turbines incorporate FR4 in their electronic control systems due to its resistance to environmental factors and electrical insulation capabilities. FR4 helps ensure the reliable operation of control circuits and sensors in renewable energy systems, supporting the efficiency and longevity of these sustainable technologies.

Why FR4 Continues to Dominate: Advantages and Future Prospects

The continued popularity of FR4 sheets can be attributed to several key advantages:

Excellent Electrical Insulation Properties

FR4 stands out for its superior electrical insulation capabilities. Composed of a glass-fiber-reinforced epoxy resin, FR4 exhibits a low dielectric constant and loss factor, making it highly effective in preventing electrical interference and signal degradation. This characteristic is crucial for modern electronic devices where precise and reliable electrical performance is essential. FR4’s ability to maintain its insulating properties across a wide range of temperatures and frequencies ensures that it remains a preferred choice for high-performance electronic applications.

High Strength and Durability

The mechanical strength and durability of FR4 are among its most significant advantages. The composite material offers excellent resistance to mechanical stress, impact, and vibration, which is vital in applications requiring robustness and reliability. FR4’s strength is attributed to its glass-fiber reinforcement, which enhances its load-bearing capabilities and extends its lifespan. This durability makes FR4 an ideal choice for demanding environments where other materials might fail or degrade quickly.

Flame-Retardant Characteristics

Safety is a paramount concern in electronics and electrical engineering, and FR4 meets this need with its inherent flame-retardant properties. The material is treated with flame-retardant additives, allowing it to resist ignition and slow the spread of flames. This characteristic is crucial for preventing fire hazards in electronic devices and circuit boards, particularly in applications where overheating or short circuits could pose significant risks.

Good Dimensional Stability

FR4 offers excellent dimensional stability, meaning it maintains its shape and size under varying environmental conditions. This property is essential for ensuring that electronic components fit precisely and function correctly over time. FR4’s low thermal expansion and contraction rates help prevent warping or distortion, which could otherwise lead to performance issues or mechanical failures in electronic assemblies.

Resistance to Moisture Absorption

Moisture resistance is another critical advantage of FR4 sheet. The material’s resistance to moisture absorption helps maintain its mechanical and electrical properties even in humid or wet conditions. This moisture resistance is particularly valuable in applications exposed to environmental factors that could otherwise cause swelling, delamination, or electrical failure. FR4’s performance in various environmental conditions underscores its reliability in diverse and challenging applications.

Cost-Effectiveness Compared to Alternative Materials

One of the key reasons for FR4’s continued dominance is its cost-effectiveness. Compared to other high-performance materials, FR4 offers a favorable balance of performance and affordability. Its relatively low production costs make it an attractive option for manufacturers looking to keep expenses down while still meeting performance and safety standards.

Future Prospects and Technological Advancements

As technology advances, the demand for FR4 sheets is expected to grow due to several emerging trends. The ongoing miniaturization of electronic devices necessitates materials that can support increasingly complex and compact designs. FR4’s versatility and reliability make it well-suited to meet these evolving requirements. The expansion of 5G networks also drives the need for high-performance materials capable of handling higher frequencies and data rates, further reinforcing FR4’s relevance.

The rise of the Internet of Things (IoT) introduces new applications and challenges that FR4 is well-positioned to address. As IoT devices become more ubiquitous, the need for durable, reliable, and cost-effective materials like FR4 will continue to increase. Additionally, the focus on sustainability in manufacturing is leading to efforts to explore the recycling and repurposing of FR4. These initiatives align with circular economy principles and could enhance FR4’s appeal by offering environmentally friendly options for material disposal and reuse.

Conclusion

In conclusion, FR4 sheets have become an integral part of our modern world, powering the electronics we rely on daily. From the circuit boards in our smartphones to critical components in industrial machinery, FR4's versatility and reliability make it a go-to material across numerous industries. As technology continues to evolve, it's clear that FR4 will remain a crucial player in shaping our electronic future.

If you're interested in learning more about FR4 sheets or other insulating materials, if you're interested in learning more about FR4 sheets or other insulating materials, contact us at info@jhd-material.com.

References

1. "FR-4 Epoxy Glass Laminate Material: The Essential Guide". Source: PCBWay.

2. "The Advantages and Applications of FR4 Material in Electronics". Source: Advanced Circuits.

3. "FR4 Material Properties and Applications". Source: Rogers Corporation.

4. "Understanding FR4 and Its Applications in Electronics". Source: ECE Tips.

5. "FR4: The Versatile Workhorse in Electronics Manufacturing". Circuit Digest.