What is the thickness of FR4 sheet?

2024-08-14 16:55:08

When it comes to electronic components and printed circuit boards (PCBs), FR4 sheet is a material that often comes up in discussions. But have you ever wondered about its thickness? In this blog post, we'll dive into the world of FR4 sheets, explore their various thicknesses, and discuss why this factor is crucial in electronics manufacturing.

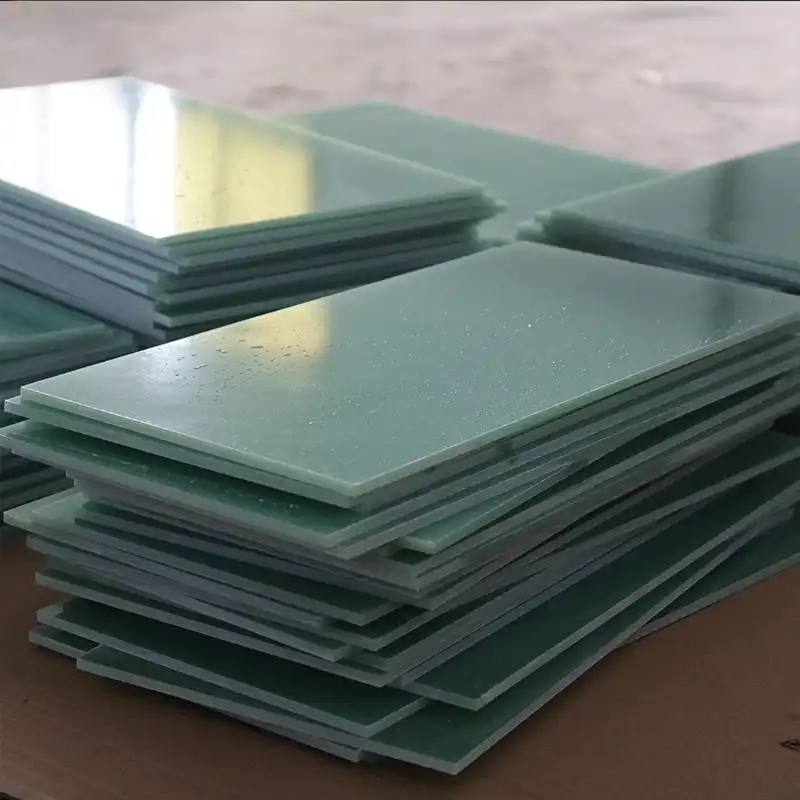

Understanding FR4 Sheet: The Backbone of Electronics

FR4, an abbreviation for Flame Retardant 4, is a crucial material in the electronics industry, revered for its blend of exceptional properties that make it indispensable in the fabrication of printed circuit boards (PCBs). This composite material, consisting of woven fiberglass cloth impregnated with an epoxy resin binder, serves as the backbone of countless electronic devices, ranging from everyday gadgets to advanced telecommunications equipment.

At its core, FR4's significance arises from its outstanding electrical insulation characteristics. This property ensures that electronic circuits remain isolated from one another, preventing unwanted electrical interference that could compromise device functionality. The electrical insulation offered by FR4 is not only effective in safeguarding against short circuits but also in maintaining the integrity of high-frequency signals, which is essential for modern electronics.

Moreover, FR4 sheets exhibit impressive mechanical strength, a feature derived from the woven fiberglass within the epoxy resin. This robust construction makes FR4 highly durable, capable of withstanding mechanical stresses and impacts that might otherwise damage more fragile materials. This durability is particularly important in applications where physical robustness is a requirement, such as in industrial machinery and rugged electronic devices.

Another pivotal aspect of FR4 is its flame retardancy. The material's inherent ability to resist ignition and slow the spread of flames is a critical safety feature in electronics. This characteristic mitigates the risk of fires resulting from electrical faults, overheating, or component failures, thereby enhancing overall safety in electronic applications.

FR4's thermal stability further contributes to its suitability for a wide range of applications. It can endure high temperatures without significant degradation, ensuring that the material remains stable and reliable even under conditions of thermal stress. This makes FR4 an ideal choice for environments where temperature fluctuations are common, such as in automotive electronics or high-power industrial devices.

The versatility of FR4 extends to its cost-effectiveness. Compared to other materials with similar properties, FR4 offers a more affordable option without compromising on performance. This cost balance is a key factor in its widespread adoption across various sectors, from consumer electronics like smartphones and laptops to more complex systems such as telecommunications infrastructure.

One of the most significant factors influencing the use of FR4 sheets is their thickness. The thickness of FR4 sheets impacts their mechanical strength, thermal performance, and suitability for different applications. Thicker sheets generally provide enhanced durability and better heat dissipation, making them suitable for high-power or mechanically demanding applications. Conversely, thinner sheets can be used where space constraints are a concern or where a lighter weight is desirable.

The Thickness Spectrum of FR4 Sheet

FR4 sheet comes in a wide range of thicknesses to cater to different electronic applications. The thickness of an FR4 sheet can vary from as thin as 0.2mm to as thick as 3mm or more. Here's a breakdown of some common FR4 sheet thicknesses and their typical uses:

0.2mm - 0.4mm: Flexible PCBs and Lightweight Devices

Thin FR4 sheets, ranging from 0.2mm to 0.4mm, are typically used in flexible printed circuit boards (PCBs) and lightweight electronic devices. These thin sheets are chosen for their flexibility, which allows them to be used in applications where space is limited and conformability is required. They are common in consumer electronics such as smartphones, tablets, and wearable devices, where the need for compact and adaptable designs is paramount. Despite their thin profile, these sheets still offer good electrical insulation and mechanical support for the components they carry.

0.8mm - 1.0mm: Standard Consumer Electronics

The 0.8mm to 1.0mm thickness range is considered the standard for many consumer electronics PCBs. This thickness provides a balanced combination of mechanical strength and thermal performance, making it suitable for a wide variety of applications, including home appliances, computers, and other everyday electronic devices. The moderate thickness ensures adequate support for electronic components while still being cost-effective and easy to fabricate. It is a versatile option that meets the needs of many standard electronic devices without compromising on performance.

1.2mm - 1.6mm: Industrial and Automotive Applications

For more demanding environments, such as industrial and automotive applications, FR4 sheets with thicknesses ranging from 1.2mm to 1.6mm are commonly used. These thicker sheets offer increased mechanical strength and durability, which are essential for applications subject to higher stress or harsher conditions. They also provide better thermal management, which is crucial in environments with high operational temperatures or where heat dissipation is a concern. The added thickness ensures that the PCBs can withstand physical impacts and vibrations, making them suitable for automotive controls, industrial machinery, and other robust applications.

2.0mm - 3.0mm: High-Power Applications and Extra Mechanical Strength

Thicker FR4 sheets, ranging from 2.0mm to 3.0mm, are used in high-power applications or where additional mechanical strength is required. These sheets are designed to handle higher electrical loads and more significant thermal stress, making them ideal for power electronics, high-current circuits, and other demanding applications. The increased thickness enhances the sheet's mechanical properties, providing superior durability and structural integrity. This makes them suitable for applications such as power supplies, high-frequency devices, and other equipment where strength and reliability are critical.

Why FR4 Sheet Thickness Matters in Electronics?

The thickness of an FR4 sheet plays a significant role in determining the characteristics and performance of the PCB and, by extension, the entire electronic device. Here's why thickness matters:

Mechanical Strength

The mechanical strength of FR4 sheets is directly related to their thickness. Thicker sheets offer enhanced mechanical properties, which are vital for applications subjected to physical stress, vibrations, or mechanical impacts. In industries such as automotive, aerospace, and industrial machinery, where devices must endure harsh conditions, thicker FR4 sheets provide the necessary rigidity and resilience. They prevent warping, bending, or cracking, which can lead to failures or malfunctions.

Heat Dissipation

Effective heat dissipation is critical in high-power electronic applications. Thicker FR4 sheets can dissipate heat more efficiently due to their increased mass and thermal conductivity. In power electronics, such as power supplies and high-current circuits, managing heat is essential to prevent overheating and ensure stable operation. Thicker sheets help in spreading and dissipating heat generated by high-power components, reducing the risk of thermal damage and enhancing the overall reliability of the PCB.

Electrical Properties

The thickness of FR4 sheets also influences their electrical properties. Specifically, it affects dielectric strength, which is the material’s ability to withstand electrical stress without breaking down. Thicker FR4 sheets generally offer higher dielectric strength, making them suitable for high-voltage applications where insulation between conductors is crucial. Additionally, the capacitance of a PCB can be affected by the thickness of the FR4 sheet. In precision electronics, where specific capacitance values are required, selecting the right thickness helps in achieving the desired electrical performance and minimizing signal interference or loss.

Weight Considerations

In applications where weight is a critical factor, such as aerospace, portable electronics, and consumer devices, the thickness of the FR4 sheet must be carefully considered. Thinner FR4 sheets are lighter, which can be advantageous in reducing the overall weight of the device. For instance, in portable devices like smartphones and tablets, using thinner FR4 sheets helps in achieving a slim and lightweight design without compromising performance. However, this must be balanced with the need for sufficient mechanical strength and heat dissipation capabilities.

Cost Implications

The cost of FR4 sheets generally increases with thickness. Thicker sheets require more material and may involve higher manufacturing and processing costs. In the design process, it is essential to balance performance requirements with budget constraints. Choosing the appropriate thickness involves evaluating the trade-offs between cost and functionality. For standard consumer electronics, where cost efficiency is important, selecting a moderately thick FR4 sheet can provide a good balance of performance and expense. In contrast, for specialized high-performance or high-reliability applications, investing in thicker sheets may be justified to meet stringent requirements.

Conclusion

In conclusion, selecting the right FR4 sheet thickness is crucial for optimizing mechanical strength, heat dissipation, and electrical performance in electronic devices. Balancing thickness with application needs and cost constraints ensures reliability and efficiency in various electronic systems.

Don't hesitate to reach out to us at info@jhd-material.com for more information or personalized assistance. Let's work together to find the perfect FR4 sheet solution for your needs!

References

1. IPC. (2018). IPC-2221: Generic Standard on Printed Board Design.

2. K. Pandey. (2020). Understanding FR4 Material Properties. Electronics Tutorials.

3. T. Harris. (2019). The Importance of PCB Thickness in Electronics. Electronics Weekly.

4. P. Zhang. (2021). Managing Heat in PCBs: The Role of FR4 Thickness. Advanced Electronics.

5. J. White. (2022). Choosing the Right PCB Material: FR4 and Alternatives. Journal of Electronic Materials.