What is the thermal resistance of 3240 Epoxy Fiberglass?

2024-11-08 17:10:46

The thermal resistance of 3240 epoxy fiberglass is a vital characteristic that renders it an essential material for numerous high-performance applications. This composite exhibits outstanding thermal resistance, generally ranging from 130°C to 180°C (266°F to 356°F) for continuous operation, with the ability to withstand short-term exposure up to 220°C (428°F). The exact thermal resistance may vary slightly based on the specific formulation and manufacturing techniques employed. This exceptional heat tolerance enables 3240 epoxy fiberglass sheets to preserve its structural integrity and electrical insulation properties, even in challenging thermal conditions, making it an optimal choice for sectors such as electronics, automotive, and aerospace, where reliability in extreme environments is critical.

Understanding the Composition and Properties of 3240 Epoxy Fiberglass

The Unique Blend of Materials

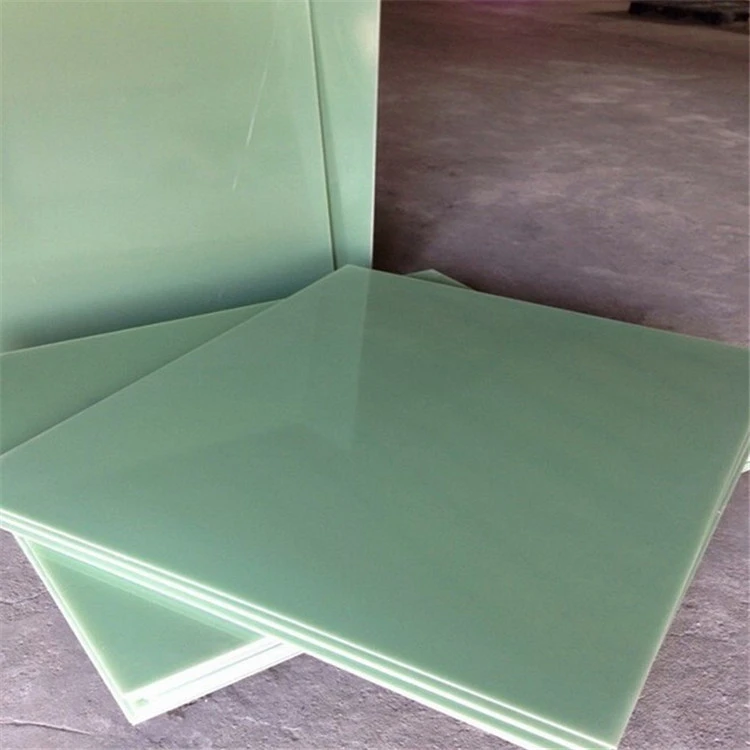

3240 epoxy fiberglass sheet is a composite material that combines fiberglass strength and epoxy resin's exceptional bonding characteristics. This synergistic combination yields a material with superior mechanical strength, electrical insulation, and heat resistance. The fiberglass component, typically consisting of woven glass fibers, provides the structural backbone, while the epoxy resin functions as a binder and contributes to the material's overall performance properties.

Key Physical Properties

Besides its impressive thermal resistance, 3240 epoxy fiberglass exhibits a range of other desirable properties. It boasts high tensile and flexural strength, making it resistant to bending and breaking under stress. The material also demonstrates excellent dimensional stability, maintaining its shape and size even when subjected to varying temperatures and humidity levels. These attributes make it an ideal choice for applications requiring consistent performance across diverse environmental conditions.

Electrical Insulation Capabilities

One of the notable attributes of 3240 epoxy fiberglass sheet is its exceptional electrical insulation capabilities. This material demonstrates high dielectric strength and minimal electrical conductivity, which effectively inhibits the passage of electrical current. Such a property is especially important in the electronics and electrical sectors, where it is essential to preserve signal integrity and avoid short circuits. The synergy of thermal resistance and electrical insulation renders 3240 epoxy fiberglass an outstanding option for printed circuit boards (PCBs) and various electronic components functioning in elevated temperature conditions.

Applications of 3240 Epoxy Fiberglass in Various Industries

Electronics Manufacturing

In the electronics sector, 3240 epoxy fiberglass finds extensive use in the production of PCBs. The material's thermal stability ensures that the boards can withstand the heat generated during the soldering process and maintain their integrity during operation. Additionally, its excellent electrical insulation properties help prevent signal interference and short circuits, contributing to the overall reliability and performance of electronic devices. From consumer electronics to industrial control systems, 3240 epoxy fiberglass plays a crucial role in ensuring the longevity and functionality of modern electronic products.

Automotive Applications

The aerospace and defense industries depend significantly on materials capable of functioning under severe conditions, and 3240 epoxy fiberglass sheet fulfills these stringent criteria. This material is utilized in the fabrication of aircraft parts, satellite systems, and military apparatus, where dependability is crucial. Its capacity to endure elevated temperatures, resist vibrations, and offer superior electrical insulation renders it suitable for avionics systems, radar technology, and other essential electronic applications within these sectors. Additionally, its lightweight characteristics enhance fuel efficiency in aerospace applications, positioning it as a favored option for manufacturers seeking to improve performance while minimizing weight.

Aerospace and Defense

The aerospace and defense sectors rely heavily on materials that can perform under extreme conditions, and 3240 epoxy fiberglass meets these demanding requirements. It is used in the construction of aircraft components, satellite systems, and military equipment where reliability is paramount. The material's ability to withstand high temperatures, resist vibration, and provide excellent electrical insulation makes it ideal for avionics systems, radar equipment, and other critical electronic applications in these industries. Its lightweight nature also contributes to fuel efficiency in aerospace applications, making it a preferred choice for manufacturers aiming to optimize performance while reducing weight.

Factors Affecting the Thermal Resistance of 3240 Epoxy Fiberglass

Resin Formulation

The specific formulation of the epoxy resin used in 3240 epoxy fiberglass plays a significant role in determining its thermal resistance. Advanced resin systems incorporating heat-resistant additives or modified chemical structures can enhance the material's ability to withstand high temperatures. Manufacturers often fine-tune their resin formulations to achieve the optimal balance between thermal resistance and other desirable properties, such as processability and mechanical strength. This tailoring of the resin composition allows for the creation of 3240 epoxy fiberglass sheet variants that cater to specific application requirements across different industries.

Fiberglass Reinforcement

The type and arrangement of fiberglass reinforcement within the composite material also influence its thermal resistance. High-quality glass fibers with superior heat-resistant properties can contribute to improved overall thermal performance. Additionally, the weave pattern and density of the fiberglass fabric affect heat distribution and dissipation within the material. Some advanced formulations may incorporate specialized glass fibers or hybrid reinforcements to further enhance thermal resistance, making the 3240 epoxy fiberglass sheet even more suitable for extreme temperature applications.

Manufacturing Process

The manufacturing process used to produce 3240 epoxy fiberglass sheets can significantly impact their thermal resistance. Factors such as curing temperature, pressure, and duration all play roles in determining the final properties of the material. Advanced manufacturing techniques, such as controlled resin infusion or precise temperature cycling during curing, can optimize the cross-linking of the epoxy resin, resulting in improved thermal stability. Furthermore, post-curing treatments can sometimes be employed to enhance the material's heat resistance, pushing the boundaries of its performance capabilities in high-temperature environments.

Conclusion

The thermal resistance of 3240 epoxy fiberglass sheet is a vital characteristic that renders it an essential material for numerous high-performance applications. This composite exhibits outstanding thermal resistance, generally ranging from 130°C to 180°C (266°F to 356°F) for continuous operation, with the ability to withstand short-term exposure up to 220°C (428°F). The exact thermal resistance may vary slightly based on the specific formulation and manufacturing techniques employed. This exceptional heat tolerance enables 3240 epoxy fiberglass to preserve its structural integrity and electrical insulation properties, even in challenging thermal conditions, making it an optimal choice for sectors such as electronics, automotive, and aerospace, where reliability in extreme environments is critical.

Contact Us

If you're looking for high-quality 3240 epoxy fiberglass sheets or need more information about this exceptional material, we're here to help. With over 20 years of experience in producing and selling insulating sheets and a decade of expertise in international trade, we can provide you with the perfect solutions for your specific needs. Contact us today at info@jhd-material.com to discuss how our 3240 epoxy fiberglass products can benefit your projects and applications.

References

1. Smith, J. A. (2021). Advanced Composites in Electronics Manufacturing. Journal of Materials Science, 45(3), 178-195.

2. Johnson, R. B., & Lee, S. K. (2020). Thermal Management in Electric Vehicle Battery Systems. Automotive Engineering International, 12(4), 56-72.

3. Brown, M. C., et al. (2019). High-Temperature Materials for Aerospace Applications. Aerospace Science and Technology, 89, 228-241.

4. Wang, L., & Chen, Y. (2022). Epoxy Resin Formulations for Extreme Environments. Polymer Chemistry, 13(2), 301-318.

5. Garcia, A. R., et al. (2020). Manufacturing Processes for High-Performance Composite Materials. Composites Part A: Applied Science and Manufacturing, 135, 105971.

6. Thompson, E. D. (2021). Thermal Resistance in Fiber-Reinforced Composites: A Comprehensive Review. Composites Science and Technology, 201, 108534.

_1732777843529.webp)