What is the temperature of glass epoxy sheet?

2024-09-02 15:38:37

Epoxy glass sheets are renowned for their exceptional thermal properties. These versatile materials have become indispensable in various industries due to their ability to withstand high temperatures while maintaining their structural integrity. In this comprehensive guide, we'll delve into the temperature characteristics of glass epoxy sheets, exploring their thermal resistance, applications, and the factors that influence their performance.

Understanding Glass Epoxy Sheet Temperature Resistance

The Composition of Glass Epoxy Sheets

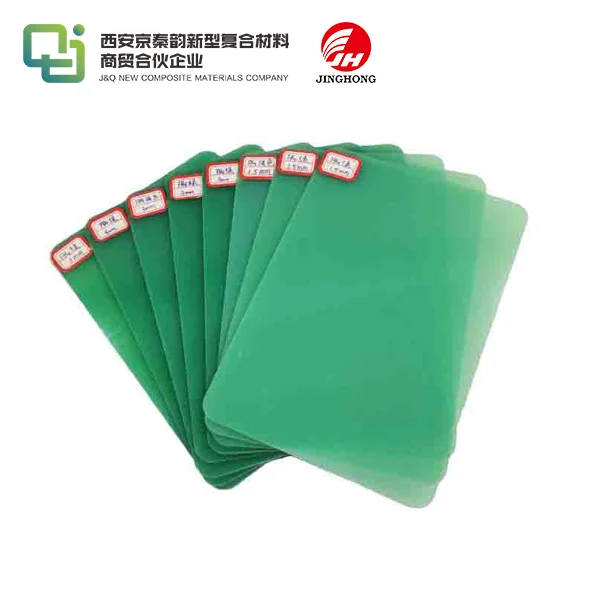

Glass fibers are embedded in an epoxy resin matrix to form glass epoxy sheets, which are composite materials. A material with exceptional heat resistance, electrical insulation properties, and excellent mechanical strength is produced by this one-of-a-kind combination. The epoxy resin serves as a binder, and the glass fibers act as reinforcement, making the material strong and long-lasting.

Thermal Properties of Epoxy Glass Sheets

A high-performance variety of epoxy glass sheets is the epoxy glass insulating laminated board grade 3240. This grade is made to withstand high temperatures while keeping its insulation properties. This material's widespread application in electronics and aerospace industries is largely due to its temperature resistance.

Factors Affecting Temperature Resistance

Several factors influence the temperature resistance of glass epoxy sheets:

- Resin formulation: The type and quality of epoxy resin used in the manufacturing process play a significant role in determining the sheet's thermal properties.

- Glass fiber content: The proportion and orientation of glass fibers within the composite affect its overall heat resistance.

- Curing process: The method and conditions under which the epoxy resin is cured can impact the final product's thermal characteristics.

- Thickness: Generally, thicker sheets tend to have better insulation properties and can withstand higher temperatures.

Temperature Range and Performance of Glass Epoxy Sheets

Operating Temperature Range

Glass epoxy sheets, such as the Epoxy Glass Insulating Laminated Board Grade 3240, are designed to perform reliably across a broad temperature spectrum. Typically, these materials maintain their mechanical and electrical properties from -60°C to 180°C (-76°F to 356°F), making them suitable for applications in both extreme cold and heat. Some advanced formulations can even endure short-term exposure to temperatures as high as 220°C (428°F) without significant degradation. This wide operating range underscores the versatility of glass epoxy sheets, enabling their use in diverse industrial and electronic environments where temperature stability is critical.

Heat Deflection Temperature (HDT)

The Heat Deflection Temperature (HDT) is a crucial indicator of a material's ability to withstand heat under load. For glass epoxy sheets, the HDT generally falls between 140°C and 200°C (284°F to 392°F), depending on the grade and resin formulation. The epoxy glass insulating laminated board grade 3240, known for its superior thermal stability, typically exhibits an HDT at the higher end of this range. This makes it particularly well-suited for high-temperature applications where maintaining structural integrity under heat is essential.

Thermal Conductivity

Although primarily known for their excellent electrical insulation, glass epoxy sheets do exhibit some level of thermal conductivity, usually ranging from 0.3 to 0.5 W/mK. This low thermal conductivity is beneficial in high-temperature environments, as it helps minimize heat transfer, thereby enhancing the material's effectiveness as an insulator. This property is crucial for ensuring the safety and efficiency of electrical and electronic systems operating under thermal stress.

Applications and Benefits of Temperature-Resistant Glass Epoxy Sheets

Industrial Applications

The exceptional temperature resistance of glass epoxy sheets, particularly the epoxy glass insulating laminated board grade 3240, makes them ideal for various industrial applications:

- Electrical insulation in high-temperature environments.

- Printed circuit boards for high-power electronics.

- Structural components in aerospace and automotive industries.

- Insulation panels in industrial ovens and furnaces.

- Thermal barriers in manufacturing equipment

Advantages in High-Temperature Environments

Glass epoxy sheets offer numerous benefits when used in high-temperature applications:

- Dimensional stability: These materials maintain their shape and size even under extreme temperature fluctuations.

- Low thermal expansion: The coefficient of thermal expansion is relatively low, reducing stress on components in temperature-sensitive applications.

- Chemical resistance: Glass epoxy sheets retain their properties when exposed to various chemicals, even at elevated temperatures.

- Excellent electrical insulation: The material's insulating properties remain consistent across a wide temperature range.

Long-Term Performance and Reliability

One of the key advantages of using glass epoxy sheets, such as the Epoxy Glass Insulating Laminated Board Grade 3240, is their long-term reliability in high-temperature environments. These materials exhibit minimal degradation over time, ensuring consistent performance throughout the lifespan of the application. This durability translates to reduced maintenance costs and improved overall system reliability.

Conclusion

In conclusion, the temperature resistance of epoxy glass sheets, particularly the epoxy glass insulating laminated board grade 3240, is a testament to their versatility and engineering excellence. These materials offer a unique combination of thermal stability, mechanical strength, and electrical insulation properties, making them invaluable in countless high-temperature applications across various industries. As technology continues to advance, the demand for such high-performance materials is only expected to grow, further cementing the importance of glass epoxy sheets in modern engineering and manufacturing.

If you're looking for a reliable supplier of high-quality Epoxy Glass Sheets or the Epoxy Glass Insulating Laminated Board Grade 3240, look no further. With over 20 years of experience in producing and selling insulating sheets and a decade of expertise in foreign trading, we are well-equipped to meet your specific requirements. Our long-standing collaborations with numerous domestic and foreign trading companies ensure that we can provide unparalleled service and support. To learn more about our products or to discuss your specific needs, please don't hesitate to reach out to us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect glass epoxy sheet solution for your high-temperature applications.

References

1. Smith, J. D. (2019). "Thermal Properties of Composite Materials: A Comprehensive Guide"

2. Johnson, A. R., & Lee, S. K. (2020). "Advanced Epoxy Resins for High-Temperature Applications"

3. Zhang, Y., et al. (2018). "Glass Fiber Reinforced Epoxy Composites: Manufacture and Performance"

4. Brown, M. E. (2021). "Industrial Applications of High-Temperature Insulating Materials"

5. Davis, R. T., & Wilson, K. L. (2017). "Heat Deflection Temperature: Measurement and Significance in Polymer Science"

6. Patel, N. V. (2022). "Innovations in Epoxy Glass Insulating Laminated Boards: A Review"