What is the difference between HDPE and plastic?

2024-10-12 17:00:47

HDPE and plastic are often grouped together in industrial discussions, but recognizing their differences is important for choosing the right material. In this detailed guide, we'll break down the key distinctions between HDPE board and general plastics by examining their unique properties, common applications, and benefits. Understanding these differences will help you make more informed decisions when selecting materials for specific uses across various industries.

HDPE: A Versatile Thermoplastic

HDPE, or High-Density Polyethylene, is a specific type of plastic that has gained immense popularity across multiple industries. Let's examine its unique characteristics and applications.

Composition and Structure of HDPE

HDPE is a type of thermoplastic made from long chains of ethylene. Its high density comes from a linear molecular structure with little branching, which creates stronger intermolecular forces. This gives HDPE greater tensile strength and durability compared to other polyethylene types, making it ideal for tough applications.

Properties that Set HDPE Apart

HDPE has several standout qualities that make it widely used across industries. It provides excellent resistance to chemicals, high impact strength, and minimal moisture absorption. Moreover, it serves as an effective electrical insulator and performs well in temperatures from -40°C to 90°C, making it versatile for a range of environments and applications.

Common Applications of HDPE

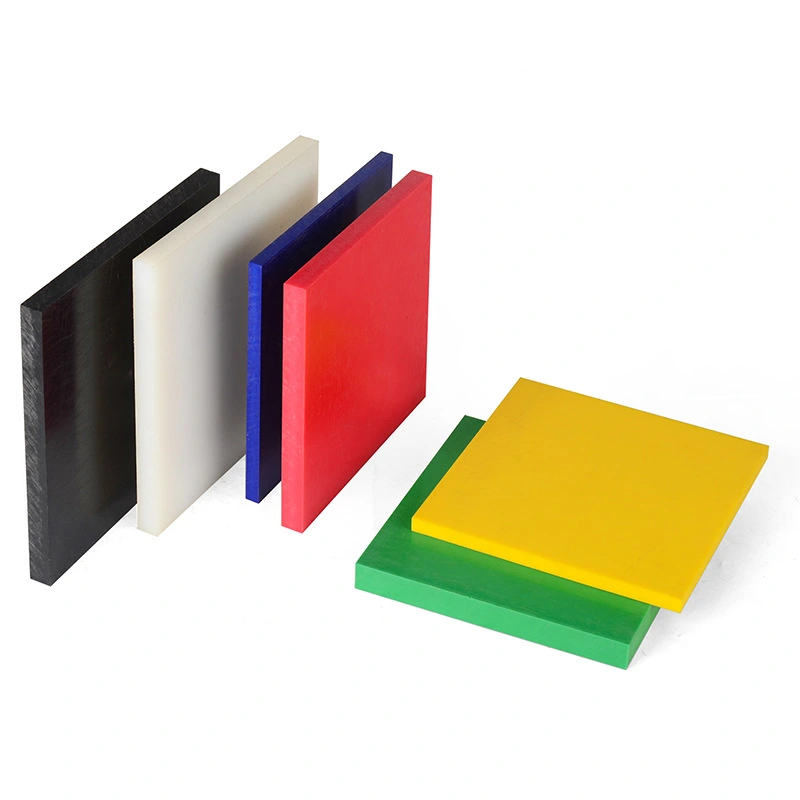

HDPE's versatility is reflected in its broad range of uses, from everyday items like bottles, pipes, and food containers to durable cutting boards. In industrial applications, HDPE boards and plastic sheets are favored for their strength and resistance to damage, making them ideal for heavy-duty environments where durability is essential.

Plastic: A Broad Category of Synthetic Materials

While HDPE is a specific type of plastic, the term "plastic" encompasses a vast array of synthetic or semi-synthetic materials. Let's explore the broader category of plastics and their characteristics.

Types of Plastics

Plastics can be categorized into two main groups: thermoplastics and thermosets. Thermoplastics, like HDPE, can be melted and reshaped multiple times, while thermosets undergo irreversible chemical changes when heated. Common types of plastics include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS).

Varied Properties of Different Plastics

The properties of plastics can vary significantly depending on their chemical composition and molecular structure. Some plastics are rigid and durable, while others are flexible and elastic. Certain plastics offer excellent thermal insulation, while others are prized for their optical clarity or electrical resistance.

Diverse Applications of Plastics

The versatility of plastics has led to their ubiquitous presence in our daily lives. From packaging materials and household items to automotive components and medical devices, plastics play a crucial role in numerous industries and applications.

Key Differences: HDPE vs. Plastic

Now that we've explored HDPE board and the broader category of plastics, let's highlight the key differences between them.

Specificity vs. Generality

The key distinction between HDPE and plastic lies in their scope. HDPE, or high-density polyethylene, is a specific type of plastic known for its unique properties, such as high strength and durability. In contrast, "plastic" is an umbrella term that refers to a broad category of synthetic materials, which includes many types of polymers, like HDPE, with varying properties and applications.

Performance and Durability

HDPE generally surpasses many other plastics in terms of strength, chemical resistance, and long-lasting durability. Its higher density and distinctive molecular structure are key factors in its exceptional performance, making it ideal for demanding applications where resilience and extended lifespan are essential. HDPE board's toughness allows it to excel in industries like construction, packaging, and piping, where reliable material strength is critical for enduring harsh conditions.

Environmental Impact and Recyclability

Although the environmental impact of plastics is a major concern, HDPE stands out as a eco-friendlier option compared to many other plastics. It is highly recyclable and can be reused multiple times without a noticeable drop in quality. This makes HDPE a more sustainable choice for applications ranging from packaging to construction materials, as it reduces waste and promotes a circular economy through efficient recycling practices.

Conclusion

In summary, though HDPE is a type of plastic, it distinguishes itself with unique characteristics that make it ideal for specific applications. Understanding these differences is essential for choosing the right material in industries ranging from construction to manufacturing. Whether you're using HDPE boards for structural projects or HDPE plastic sheets for industrial purposes, recognizing its durability, strength, and versatility can result in better material performance and more efficient project outcomes.

Contact Us

With over 20 years of experience in producing and selling insulating sheets and more than a decade in foreign trading, our team at J&Q is well-equipped to provide expert advice on HDPE and other materials. If you're looking for high-quality HDPE products or need more information about their applications, don't hesitate to reach out to us at info@jhd-material.com. Our extensive experience and commitment to excellence ensure that we can provide the perfect solutions for your material needs.

References

1. Thompson, R. C., et al. "Plastics, the environment and human health: current consensus and future trends." Philosophical Transactions of the Royal Society B: Biological Sciences, 2009.

2. Andrady, A. L., & Neal, M. A. "Applications and societal benefits of plastics." Philosophical Transactions of the Royal Society B: Biological Sciences, 2009.

3. Peacock, A. J. "Handbook of Polyethylene: Structures: Properties, and Applications." Marcel Dekker, Inc., 2000.

4. Vasile, C., & Pascu, M. "Practical Guide to Polyethylene." Rapra Technology Limited, 2005.

5. Wypych, G. "Handbook of Polymers." ChemTec Publishing, 2016.

6. Crawford, R. J., & Martin, P. J. "Plastics Engineering." Butterworth-Heinemann, 2020.