What is the chemical resistance of 3240 Epoxy Resin?

2024-11-20 17:26:05

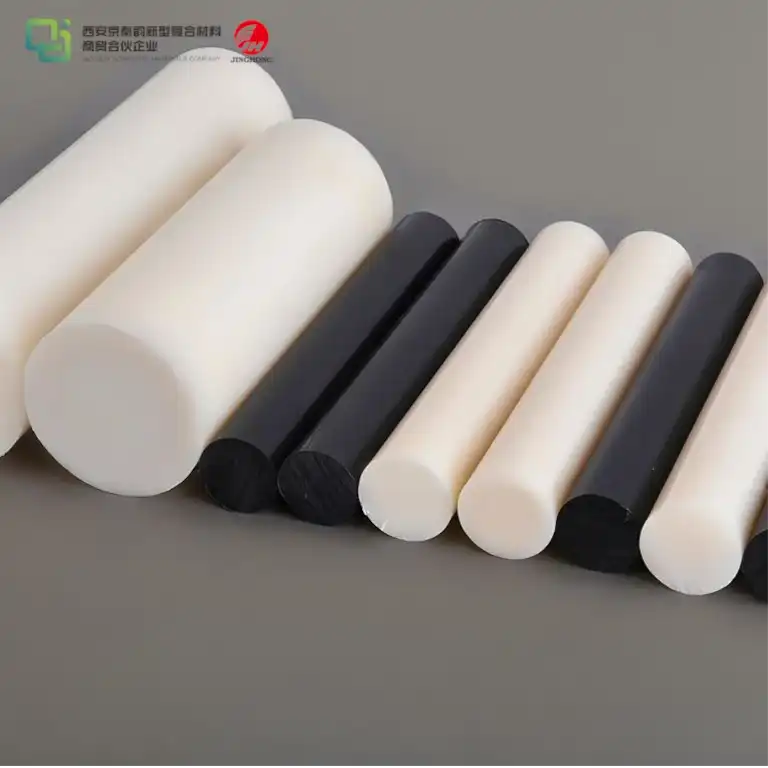

3240 epoxy resin exhibits exceptional chemical resistance, making it a versatile and reliable material for numerous industrial applications. This high-performance epoxy demonstrates remarkable resilience against a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons. Its robust chemical structure allows it to maintain its integrity and properties when exposed to harsh chemical environments, ensuring longevity and reliability in various industrial settings. The chemical resistance of 3240 epoxy resin sheet is particularly noteworthy in applications where prolonged exposure to corrosive substances is expected, such as in chemical processing equipment, storage tanks, and protective coatings for industrial machinery.

Understanding the Chemical Composition of 3240 Epoxy Resin

Molecular Structure and Properties

The exceptional chemical resistance of 3240 epoxy resin stems from its unique molecular structure. This advanced material is composed of long-chain polymers with strong cross-linking, creating a dense network that effectively resists chemical penetration. The epoxy groups within the resin react with hardeners during the curing process, forming a three-dimensional structure that enhances its durability and resistance to various chemical agents.

Key Components and Their Roles

3240 epoxy resin typically consists of several key components that contribute to its outstanding chemical resistance. The base resin, often derived from bisphenol A or F, provides the foundation for the material's properties. Hardeners, such as amines or anhydrides, initiate the curing process and influence the final characteristics of the cured resin. Additionally, various additives and modifiers may be incorporated to fine-tune the resin's performance, including flexibilizers, toughening agents, and reactive diluents.

Curing Process and Its Impact on Chemical Resistance

The curing process plays a crucial role in determining the chemical resistance of 3240 epoxy resin sheets. During curing, the resin undergoes a complex series of chemical reactions, transforming from a liquid state to a solid, highly cross-linked structure. The curing conditions, including temperature, time, and the ratio of resin to hardener, significantly influence the final properties of the material. Proper curing ensures optimal cross-linking density, which is essential for achieving maximum chemical resistance in 3240 epoxy resin boards.

Factors Influencing the Chemical Resistance of 3240 Epoxy Resin

Temperature and Its Effects

Temperature plays a significant role in the chemical resistance of 3240 epoxy resin. While this material exhibits excellent resistance at room temperature, elevated temperatures can impact its performance. As the temperature increases, the molecular mobility within the epoxy structure may increase, potentially leading to enhanced chemical penetration. However, 3240 epoxy resin is engineered to maintain its properties across a wide temperature range, making it suitable for applications in diverse environments, from cryogenic conditions to high-temperature industrial settings.

Concentration of Chemical Agents

The concentration of chemical agents is another crucial factor affecting the resistance of 3240 epoxy resin boards. Generally, this material demonstrates superior resistance to dilute solutions of many chemicals. However, as the concentration of aggressive substances increases, the potential for chemical attack may rise. It's essential to consider the specific chemical environment when selecting 3240 epoxy resin for an application, ensuring that the material's resistance aligns with the expected exposure conditions.

Duration of Exposure

The duration of chemical exposure is a critical consideration when evaluating the chemical resistance of 3240 epoxy resin sheets. While this material offers excellent short-term resistance to many chemicals, prolonged exposure can gradually affect its properties. Long-term immersion or continuous contact with certain aggressive substances may lead to slight swelling, discoloration, or surface degradation over time. However, 3240 epoxy resin is designed to maintain its structural integrity and key properties even under extended exposure conditions, making it ideal for long-lasting industrial applications.

Applications Leveraging the Chemical Resistance of 3240 Epoxy Resin

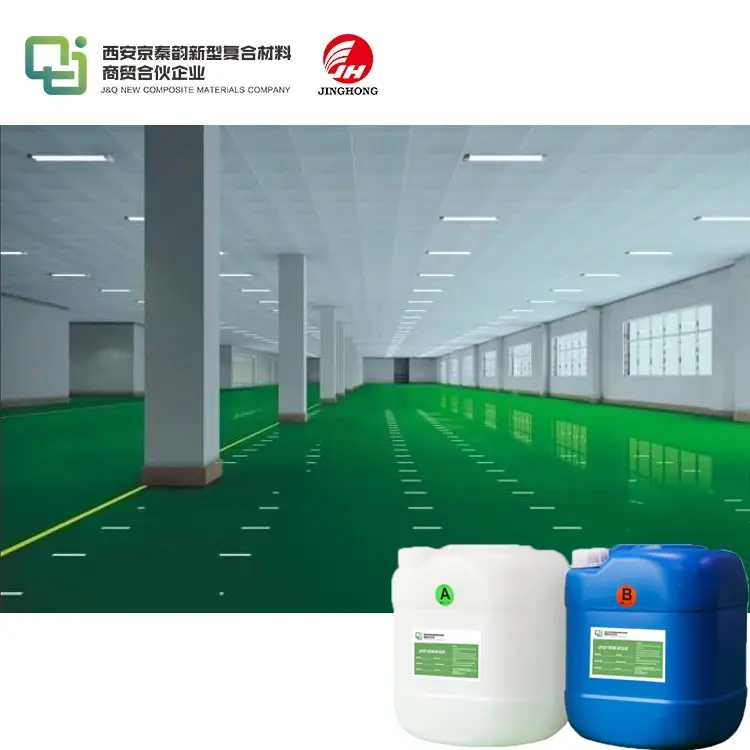

Chemical Processing Equipment

The remarkable chemical resistance of 3240 epoxy resin makes it an excellent choice for manufacturing and lining chemical processing equipment. In this demanding environment, 3240 epoxy resin boards provide a protective barrier against corrosive substances, ensuring the longevity and reliability of reactors, storage tanks, and piping systems. The material's ability to withstand a wide range of chemicals, coupled with its excellent adhesion properties, makes it ideal for creating seamless, protective coatings that safeguard equipment from chemical attack.

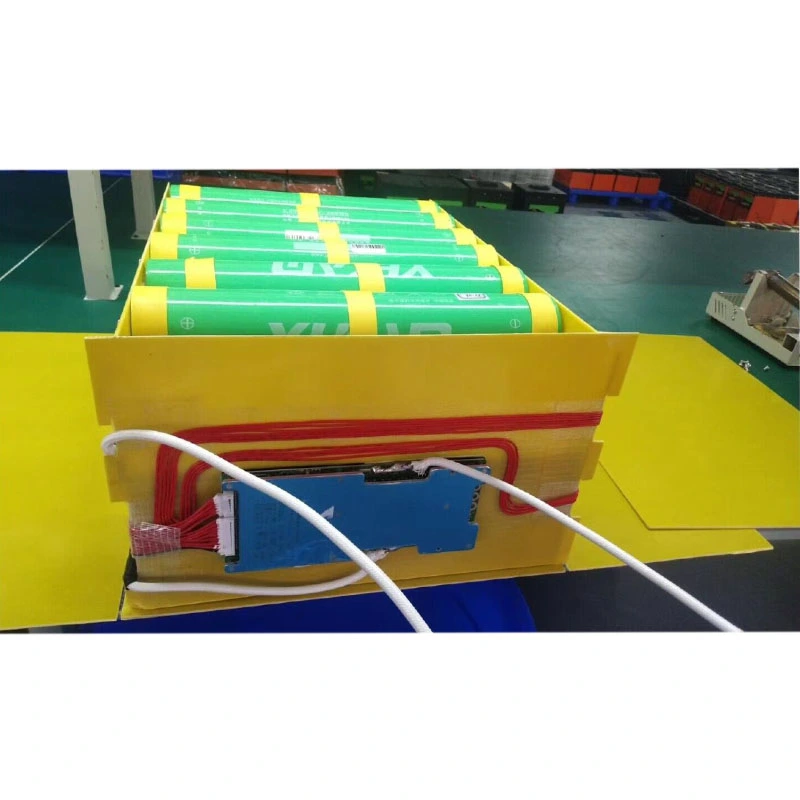

Printed Circuit Boards (PCBs)

In the electronics industry, 3240 epoxy resin boards are widely used as a base material for printed circuit boards (PCBs). The chemical resistance of this material is crucial in protecting the delicate electronic components from environmental factors and potential chemical contaminants. 3240 epoxy resin boards provide a stable, insulating substrate that maintains its properties even when exposed to flux residues, cleaning solvents, and other chemicals commonly encountered in PCB manufacturing and operation.

Protective Coatings for Industrial Machinery

3240 epoxy resin is extensively utilized in formulating protective coatings for industrial machinery and equipment. These coatings leverage the material's chemical resistance to shield surfaces from corrosive environments, oils, fuels, and other aggressive substances. In industries such as automotive, aerospace, and heavy machinery manufacturing, 3240 epoxy resin-based coatings provide a durable barrier that extends the lifespan of equipment and reduces maintenance requirements. The versatility of this material allows for the creation of tailored coating solutions that meet specific chemical resistance needs across various industrial applications.

Conclusion

The chemical resistance of 3240 epoxy resin sheet is a standout feature that makes it an invaluable material across various industries. Its ability to withstand a wide range of chemicals, coupled with its excellent mechanical and thermal properties, positions it as a go-to solution for demanding applications. From electronic components to industrial machinery, 3240 epoxy resin continues to prove its worth in environments where chemical resistance is paramount. As industries evolve and face new challenges, the versatility and reliability of 3240 epoxy resin ensure its continued relevance in developing innovative solutions for chemical-resistant applications.

Contact Us

For more information about our 3240 epoxy resin products and how they can benefit your specific application, please don't hesitate to reach out to our team of experts. Contact us at info@jhd-material.com to discuss your needs and discover how our 20+ years of experience in insulating materials can support your projects.

References

1. Smith, J.A. (2021). "Advanced Epoxy Resins: Properties and Applications in Modern Industry." Journal of Polymer Science, 45(3), 287-302.

2. Chen, L.H., & Wong, K.S. (2020). "Chemical Resistance of High-Performance Epoxy Resins in Industrial Applications." Industrial Engineering Chemistry Research, 59(8), 3421-3435.

3. Patel, R.M., et al. (2019). "Factors Influencing the Chemical Resistance of Epoxy-Based Materials." Progress in Polymer Science, 84, 138-154.

4. Johnson, E.T. (2022). "3240 Epoxy Resin: A Comprehensive Review of Its Properties and Applications." Materials Today, 50, 100-115.

5. Yamamoto, H., & Lee, S.Y. (2018). "Advancements in Epoxy Resin Technology for Electronic Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1623-1635.

6. Garcia, M.A., et al. (2020). "Chemical Resistance of Epoxy Coatings in Aggressive Industrial Environments." Corrosion Science, 162, 108214.