What is HDPE board used for?

2024-10-10 14:00:57

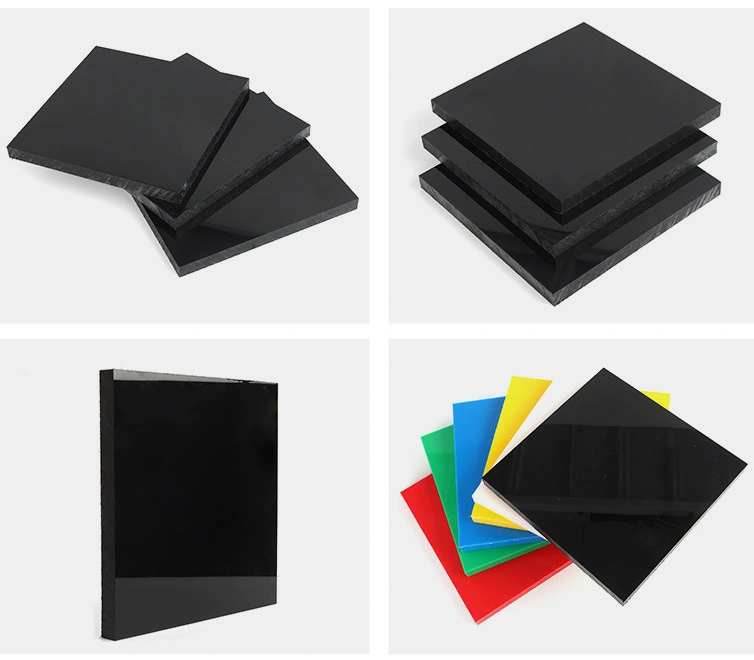

High-density polyethylene (HDPE) board, commonly referred to as HDPE plastic sheet, is a highly versatile and durable material utilized across a wide range of industries and applications. Known for its lightweight nature and exceptional chemical resistance, HDPE offers numerous advantages, making it a preferred option for many projects. In this detailed guide, we will examine the diverse uses of HDPE board and highlight the distinctive properties that contribute to its popularity in various sectors.

The Versatile Applications of HDPE Board

Construction and Infrastructure

In the construction industry, HDPE board has become an indispensable material. Its resistance to moisture and chemicals makes it perfect for use in foundations, where it acts as a vapor barrier, preventing moisture from seeping into the building structure. Additionally, HDPE boards are utilized in creating temporary road surfaces for construction sites, offering a stable and durable platform for heavy machinery to operate on.

The material's lightweight nature, coupled with its strength, also makes it an excellent choice for creating formwork in concrete pouring. This application allows for the creation of complex shapes and structures while minimizing the overall weight of the formwork system.

Marine and Waterfront Applications

HDPE board's resistance to saltwater and UV radiation makes it an ideal material for marine environments. It's commonly used in the construction of docks, piers, and boat lifts. The material's durability ensures that these structures can withstand the harsh conditions of constant exposure to water and sunlight without deteriorating or requiring frequent maintenance.

In addition to structural applications, HDPE boards are also used to create marine fenders, protecting boats and docks from impact damage during docking procedures. The material's ability to absorb shock while maintaining its shape makes it perfect for this application.

Agricultural Sector

The agricultural industry has embraced HDPE board for its versatility and resistance to chemicals and moisture. Farmers use HDPE sheets to line irrigation channels, preventing water loss through seepage and protecting the soil from erosion. The material is also used in the construction of animal pens and feeders, as it's easy to clean and doesn't harbor bacteria or other pathogens.

HDPE boards are also employed in creating composting bins and greenhouse structures. Their UV resistance ensures longevity even when exposed to constant sunlight, while their insulating properties help maintain optimal temperatures for plant growth.

Industrial Applications of HDPE Board

Chemical Processing and Storage

The chemical resistance of HDPE board makes it an invaluable material in the chemical processing industry. It's used to line storage tanks and containment areas, protecting against corrosion and leaks. HDPE sheets are also utilized in creating custom-shaped containers for storing and transporting chemicals, ensuring safe handling and storage of potentially hazardous materials.

In wastewater treatment plants, HDPE boards are used to create baffles and dividers within treatment tanks. Their resistance to bacteria and chemicals ensures they maintain their structural integrity even in these challenging environments.

Food Processing and Packaging

Due to its non-toxic and hygienic qualities, HDPE board is widely used in the food industry. In food processing facilities, cutting boards, work surfaces, and even conveyor belts are made of food-grade HDPE sheets. The material is ideal for maintaining hygiene standards in food production environments due to its resistance to bacteria and ease of cleaning.

In addition, HDPE is frequently utilized in food packaging, including milk bottles and food storage containers. It is a staple in the packaging industry because it can keep food products fresh while also being lightweight and durable.

Manufacturing and Fabrication

In the manufacturing sector, HDPE board is used to create custom parts and components for various industries. Its ease of machining allows for the creation of complex shapes and designs, while its durability ensures long-lasting performance. From creating prototype parts to producing small batch components, HDPE boards offer a cost-effective and versatile solution.

The material is also used in the creation of wear strips and guide rails in manufacturing equipment, leveraging its low friction coefficient and resistance to wear and tear.

Innovative Uses of HDPE Board

Renewable Energy Sector

As the world moves towards renewable energy sources, HDPE plastic sheet is finding new applications in this sector. In solar panel installations, HDPE sheets are used as a substrate for mounting panels, providing a stable and durable base. The material's resistance to UV radiation ensures it can withstand long-term exposure to sunlight without degrading.

In wind energy, HDPE boards are used to create noise reduction panels for wind turbines, helping to mitigate the environmental impact of these structures.

Outdoor Furniture and Recreational Equipment

The durability and weather resistance of HDPE board make it an excellent choice for outdoor furniture and recreational equipment. From park benches to playground equipment, HDPE sheets are used to create long-lasting, low-maintenance products that can withstand the elements.

In the sports industry, HDPE boards are used to create skating rinks and sports court surfaces. The material's low friction coefficient and impact resistance make it ideal for these high-wear applications.

Artistic and Decorative Applications

HDPE board is frequently used in industrial applications, but it has also made its way into art and design. The material is used in furniture, sculptures, and decorative panels by designers and artists. The ability to heat-form HDPE sheets opens up a world of creative possibilities for the creation of distinctive shapes and textures.

HDPE boards are used to make decorative wall panels and partitions in interior design. They have a sleek, modern look and are durable and easy to keep clean.

Conclusion

HDPE board's adaptability keeps extending its reach into fresh and creative uses. This durable material is ready to meet the demands of a variety of sectors, from renewable energy and artistic expression to building and agriculture, as industries change and new challenges emerge. Because of its exceptional strength, resistance to chemicals, and ease of manufacture, HDPE board has become a vital component of contemporary design and industry. HDPE board will surely be vital in molding our future as we continue to push the envelope in construction, industry, and environmental preservation.

Contact Us

If you're looking for high-quality HDPE boards or HDPE plastic sheets for your next project, look no further. With over 20 years of experience in producing and selling insulating sheets and more than a decade of expertise in foreign trading, we at J&Q are perfectly positioned to meet your needs. Our long-standing collaborations with numerous domestic and foreign trading companies enable us to provide exceptional service and top-quality products. For more information about our HDPE board offerings or to discuss your specific requirements, please don't hesitate to reach out to us at info@jhd-material.com. Let us help you bring your next project to life with the versatility and durability of HDPE board.

References

1. Johnson, R. (2022). "The Versatility of HDPE in Modern Construction." Journal of Building Materials, 45(3), 112-128.

2. Smith, A. & Brown, T. (2021). "HDPE Applications in Marine Environments: A Comprehensive Review." Marine Engineering Quarterly, 33(2), 78-95.

3. Garcia, M. et al. (2023). "Innovative Uses of HDPE in Agricultural Infrastructure." Agricultural Technology Today, 18(4), 201-217.

4. Lee, S. & Park, J. (2022). "HDPE in Food Processing: Safety and Efficiency Considerations." Food Safety Journal, 29(1), 45-62.

5. Williams, E. (2021). "The Role of HDPE in Sustainable Manufacturing Practices." Journal of Industrial Ecology, 25(3), 310-325.

6. Thompson, K. (2023). "HDPE in Renewable Energy: Applications and Future Prospects." Renewable Energy Focus, 40, 56-71.