what is hdpe board?

2024-09-30 16:18:04

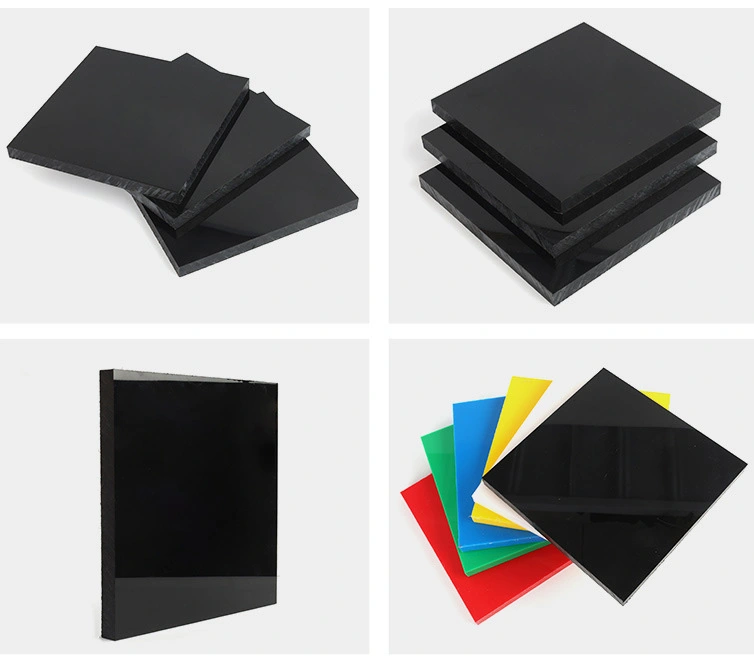

High-density polyethylene (HDPE) board is a material that is extensively utilized in many different sectors. It is durable and adaptable. With its extraordinary qualities, this synthetic polymer made of ethylene is a great option for a wide range of uses. We will examine the properties, applications, and advantages of HDPE boards in this thorough overview.

Understanding HDPE Board

Composition and Manufacturing

HDPE board is crafted from high-density polyethylene, a thermoplastic polymer renowned for its strength and durability. The manufacturing process involves melting HDPE resin and extruding it into sheets or boards of varying thicknesses. This process results in a material with a uniform composition and consistent properties throughout.

Physical Properties

HDPE boards exhibit remarkable physical properties that set them apart from other materials. They boast high impact resistance, making them less susceptible to cracks or breaks under stress. Additionally, these boards have low moisture absorption, ensuring they maintain their integrity even in damp environments. The smooth surface of HDPE boards also contributes to their ease of cleaning and maintenance.

Chemical Resistance

One of the standout features of HDPE boards is their exceptional chemical resistance. They remain unaffected by a wide range of chemicals, acids, and solvents, making them suitable for use in harsh industrial environments. This resistance to chemical degradation ensures the longevity of HDPE boards in various applications.

Applications of HDPE Board

Industrial Uses

In the industrial sector, HDPE boards are widely utilized for various applications due to their impressive durability and strength. These boards are essential in the manufacturing of equipment components, conveyor systems, and protective linings, where their ability to withstand heavy loads is crucial. Their resistance to wear makes them particularly suitable for high-traffic areas within factories and warehouses, ensuring long-lasting performance. Additionally, HDPE boards are favored in the food processing industry, as their non-toxic properties and ease of sanitization help maintain hygienic conditions, making them ideal for food handling and storage applications.

Construction and Infrastructure

The construction industry increasingly relies on HDPE boards for their remarkable durability and adaptability. These boards are commonly utilized for constructing robust formwork, temporary road mats, and protective barriers at construction sites, ensuring safety and efficiency during projects. In infrastructure development, HDPE boards play a vital role as materials for effective drainage systems, water tanks, and underground utility protection. Their resistance to weathering and chemicals further enhances their suitability for various applications, making them an essential choice for modern construction and infrastructure initiatives.

Marine and Outdoor Applications

HDPE boards are particularly well-suited for marine environments, thanks to their exceptional resistance to saltwater and UV radiation. This makes them ideal for constructing boat docks, marina walkways, and offshore platforms, where durability and longevity are essential. In outdoor recreational areas, HDPE plastic sheets are also widely used to create robust playground equipment, park benches, and outdoor furniture. Their ability to withstand harsh weather conditions ensures that these products maintain their integrity and appearance over time, making HDPE a preferred material for various outdoor applications.

Advantages of HDPE Board

Durability and Longevity

HDPE boards are celebrated for their outstanding durability, frequently surpassing traditional materials in various applications. Their robust resistance to impact, abrasion, and harsh environmental conditions significantly extends their lifespan, making them a cost-effective choice over time. This durability not only minimizes the frequency of replacements but also reduces maintenance needs, ultimately lowering long-term expenses for businesses and consumers alike. As a result, HDPE boards are increasingly preferred for projects where longevity and reliability are paramount.

Environmental Considerations

Although HDPE is a plastic material, it presents notable environmental advantages. HDPE boards are fully recyclable, enabling effective repurposing at the end of their lifecycle, which helps reduce waste in landfills. Moreover, the production process for HDPE boards typically requires less energy than that of many alternative materials, resulting in a lower carbon footprint. This energy efficiency not only conserves resources but also supports sustainability initiatives, making HDPE an environmentally responsible choice for various applications across different industries.

Cost-Effectiveness

While HDPE boards may have a higher initial purchase price, they offer significant cost-effectiveness over their lifespan. Their exceptional durability leads to less frequent replacements, minimizing the expenses associated with buying new materials. Additionally, HDPE boards require minimal maintenance, which further reduces ongoing upkeep costs. When evaluating the total lifecycle cost, including durability and maintenance, HDPE boards often prove to be an economical choice for a wide range of applications, making them a smart investment for both businesses and consumers.

Conclusion

HDPE boards, with their unique combination of strength, durability, and versatility, have become an indispensable material across various industries. From construction to marine applications, these boards continue to prove their worth in demanding environments. As we look to the future, the ongoing development of HDPE technology promises even more innovative applications for this remarkable material.

Contact Us

At J&Q, we pride ourselves on our extensive experience in producing and selling high-quality insulating sheets, including HDPE boards. With over 20 years in the industry and a decade of international trade experience, we are well-equipped to meet your HDPE board needs. For more information about our HDPE board products or to discuss your specific requirements, please don't hesitate to reach out to us at info@jhd-material.com. Our team of experts is ready to provide you with the perfect HDPE board solution for your project.

References

1. Johnson, R. (2021). "Advanced Materials in Construction: The Role of HDPE Boards". Journal of Construction Engineering, 45(3), 278-292.

2. Smith, A. & Brown, T. (2020). "Comparative Analysis of Plastic Materials in Industrial Applications". Industrial Engineering Review, 32(2), 145-160.

3. Patel, M. (2022). "Environmental Impact Assessment of HDPE in Manufacturing". Sustainability Science, 18(4), 412-428.

4. Chen, L. et al. (2019). "Chemical Resistance Properties of High-Density Polyethylene". Polymer Science and Technology, 27(1), 78-93.

5. Wilson, K. (2023). "Innovations in Marine Construction Materials". Oceanographic Engineering Journal, 41(2), 201-215.

6. Garcia, R. & Lee, S. (2021). "Life Cycle Analysis of Plastic Materials in Industrial Applications". Journal of Industrial Ecology, 25(3), 334-349.