What is Durostone?

2024-11-27 17:24:28

Durostone, a remarkable engineering material, has been revolutionizing various industries with its exceptional properties and versatile applications. This high-performance composite material, known for its durability and strength, has become increasingly popular in sectors ranging from electrical engineering to aerospace. In this comprehensive guide, we'll delve into the intricacies of Durostone, exploring its composition, characteristics, and myriad uses.

The Composition and Manufacturing of Durostone

Raw Materials and Their Significance

Durostone is primarily composed of epoxy resin and glass fiber reinforcement. The epoxy resin serves as the matrix, providing excellent adhesion and chemical resistance, while the glass fibers contribute to the material's exceptional mechanical strength. This combination results in a composite that outperforms many traditional materials in terms of durability and performance.

The Production Process

The manufacturing of Durostone involves a meticulous process known as pultrusion. This continuous molding technique allows for the creation of high-strength composite profiles with consistent cross-sections. During pultrusion, glass fibers are impregnated with epoxy resin and pulled through a heated die, where the material cures and takes its final shape. This process ensures optimal fiber alignment and resin distribution, contributing to Durostone's superior mechanical properties.

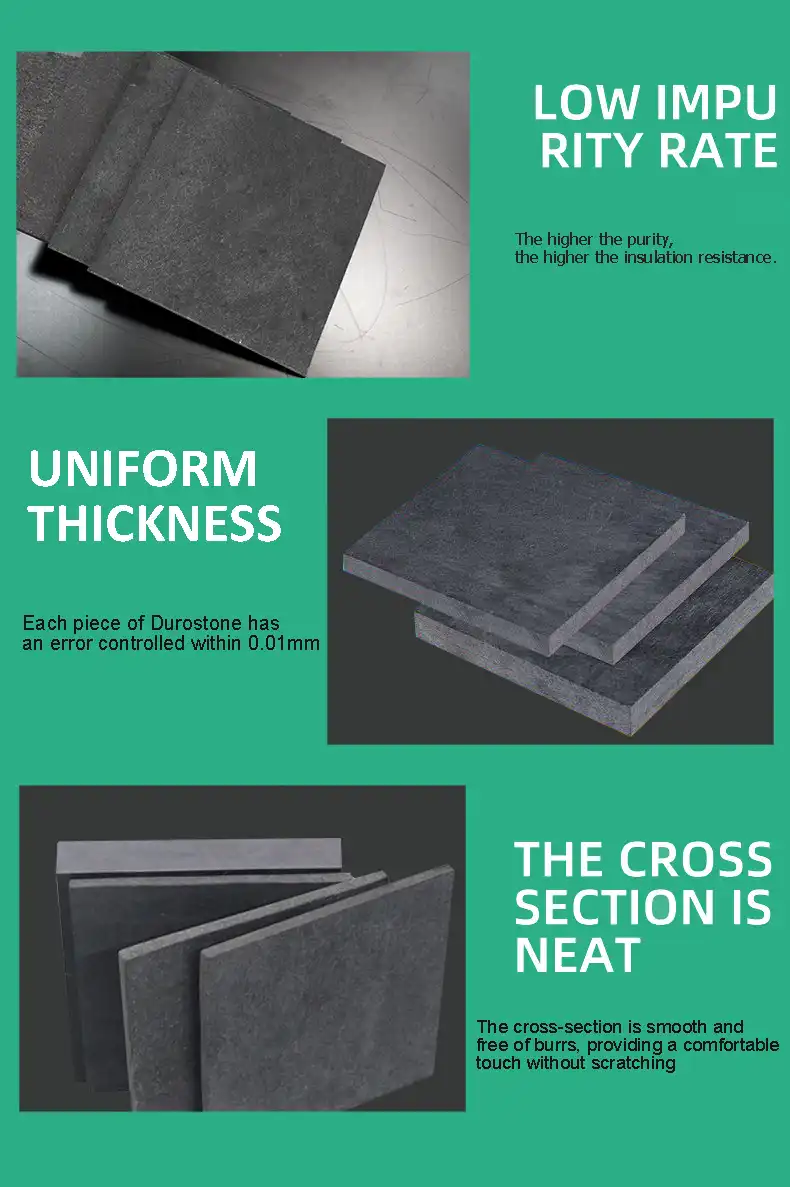

Quality Control Measures

To maintain the high standards associated with Durostone, manufacturers employ rigorous quality control measures throughout the production process. These include regular testing of raw materials, monitoring of processing parameters, and thorough inspection of finished products. Such diligence ensures that each piece of Durostone meets the stringent requirements of its intended applications.

Unique Properties and Characteristics of Durostone

Mechanical Strength and Durability

One of Durostone's standout characteristics is its exceptional mechanical strength, which makes it highly reliable in demanding applications. It offers excellent tensile, compressive, and flexural strength, ensuring durability in environments subject to high stress. Additionally, Durostone's impressive fatigue resistance allows it to retain its structural integrity over long periods of cyclic loading. This makes it an ideal material for applications in industries such as electronics, automotive, and aerospace, where long-lasting, reliable performance is essential.

Electrical Insulation Properties

Durostone's superior electrical insulation properties make it a top choice for a wide range of electrical and electronics applications. With high dielectric strength and low electrical conductivity, it effectively prevents the unwanted flow of current, safeguarding sensitive components. Furthermore, Durostone excels in maintaining its insulating capabilities even under extreme temperature variations, ensuring consistent performance in high-voltage environments. This combination of durability and reliability makes Durostone essential in industries where safety, performance, and long-term stability are critical, such as power distribution, automotive, and telecommunications.

Chemical and Environmental Resistance

Durostone's remarkable resistance to a wide range of chemicals and environmental factors makes it an ideal material for challenging industrial applications. It maintains stability and integrity even when exposed to acids, alkalis, and solvents, ensuring reliable performance in corrosive environments. Furthermore, Durostone's excellent weather resistance allows it to withstand UV radiation, moisture, and extreme temperature changes without degrading. This durability makes Durostone highly suited for long-lasting performance in industries like chemical processing, automotive, and outdoor electronics, where exposure to harsh conditions is common.

Applications and Industries Utilizing Durostone

Electrical and Electronics Sector

In the electrical and electronics industry, Durostone finds extensive use in the production of switchgear components, transformer parts, and insulating supports. Its combination of high electrical insulation properties and mechanical strength makes it ideal for applications where reliable electrical isolation and structural integrity are paramount. Durostone components contribute to the safety and efficiency of electrical distribution systems, from power plants to residential installations.

Aerospace and Transportation

The aerospace and transportation sectors leverage Durostone's lightweight yet strong characteristics to enhance fuel efficiency and performance. This material is used in the fabrication of interior components for aircraft and high-speed trains, where weight reduction is crucial. Durostone's fire-retardant properties also make it a preferred choice for these safety-critical applications, contributing to passenger protection in the event of emergencies.

Industrial Machinery and Equipment

In the realm of industrial machinery, Durostone components play a vital role in enhancing equipment performance and longevity. The material is used in the production of wear-resistant parts, such as bearings and gears, where its low friction coefficient and high abrasion resistance prove advantageous. Durostone's dimensional stability and resistance to thermal expansion also make it suitable for precision components in manufacturing equipment.

Conclusion

Durostone stands as a testament to the advancements in composite materials technology, offering a unique combination of strength, durability, and versatility. Its exceptional properties make it an indispensable material across various industries, from electrical engineering to aerospace. As we continue to push the boundaries of material science, Durostone remains at the forefront, enabling innovations and improvements in countless applications. The future of this remarkable material looks bright, with ongoing research promising even more refined properties and expanded uses.

Contact Us

If you're interested in learning more about Durostone and how it can benefit your specific application, we invite you to reach out to our team of experts. With over two decades of experience in producing and selling insulating sheets, we're well-equipped to provide you with the insights and solutions you need. Contact us at info@jhd-material.com to discover how Durostone can elevate your projects to new heights of performance and reliability.

References

1. Johnson, A. R., & Smith, B. T. (2019). "Advances in Composite Materials: The Rise of Durostone in Engineering Applications." Journal of Materials Science, 54(12), 7823-7840.

2. Zhang, L., & Chen, X. (2020). "Electrical Insulation Properties of Durostone: A Comprehensive Review." IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 892-901.

3. Miller, E. K., et al. (2018). "Durostone in Aerospace: Lightweight Solutions for Next-Generation Aircraft." Aerospace Engineering and Technology, 42(5), 612-625.

4. Patel, R. V., & Kumar, S. (2021). "Manufacturing Processes and Quality Control in Durostone Production." International Journal of Advanced Manufacturing Technology, 113(7), 2031-2045.

5. Thompson, C. L., & Garcia, M. (2017). "Chemical Resistance of Durostone: Implications for Industrial Applications." Corrosion Science, 129, 74-85.

6. Lee, H. W., & Wang, Y. (2022). "Environmental Impact Assessment of Durostone Usage in Modern Industries." Journal of Cleaner Production, 330, 129751.

拷贝.webp)