What is a smt pallet?

2024-11-29 16:28:27

In the world of electronics manufacturing, precision and efficiency are paramount. One crucial component that plays a significant role in the surface mount technology (SMT) process is the SMT pallet. This article explores the complexities of SMT pallets, their significance, and how they support the smooth manufacturing of electronic devices.

Understanding SMT Pallets

Definition and Purpose

An SMT pallet, also known as a PCB carrier or SMT fixture, is a specialized tool designed to hold and transport printed circuit boards (PCBs) during the surface mount assembly process. These pallets are designed to give PCBs stability, security, and accurate placement as they pass through different production stages.

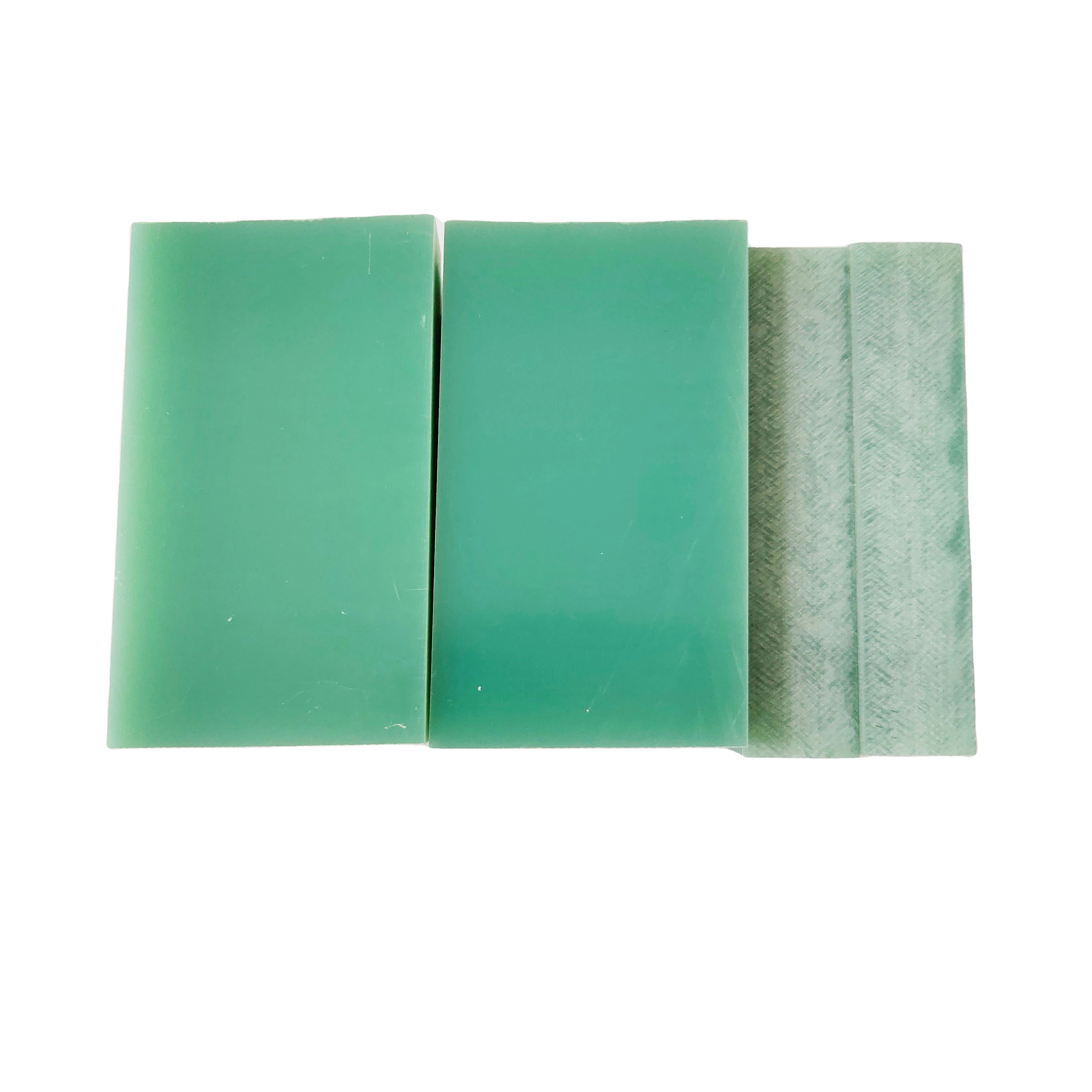

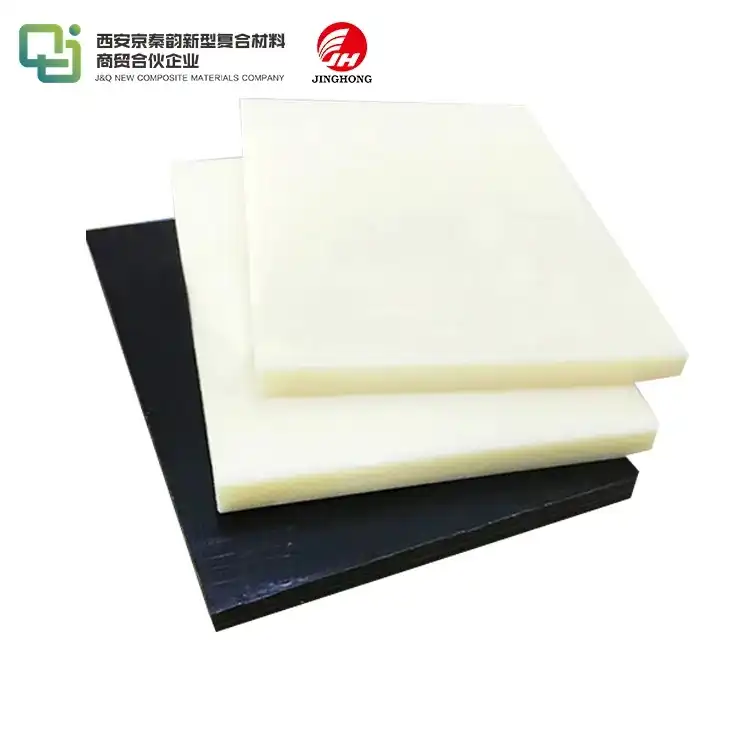

Material Composition

SMT pallets are typically fabricated from high-performance materials such as FR-4, aluminum, or advanced polymers. The durability, dimensional stability, and resistance to heat and chemicals encountered during the manufacturing process are the reasons behind the selection of these materials. The material selection is influenced by a number of variables, including the assembly line's particular requirements, the PCB's complexity, and the pallet's intended lifespan.

Design Features

The design of SMT pallets incorporates several key features to ensure optimal performance. These may include:

- Precise cutouts or recesses to accommodate PCBs of varying sizes and shapes

- Registration pins or alignment features for accurate board positioning

- Anti-static properties to prevent electrostatic discharge (ESD) damage

- Heat-resistant coatings to withstand high temperatures during reflow soldering

- Reinforced edges to enhance durability and prevent warping

The Role of SMT Pallets in Electronics Manufacturing

Enhancing Production Efficiency

SMT pallets are essential in optimizing the electronics manufacturing process by providing a consistent and reliable platform for handling printed circuit boards (PCBs). These pallets' standardized design makes it easier for automated machinery to interact with them, enabling quicker and more accurate operation. Smoother production runs result from this uniformity since it lessens the need for manual intervention and the possibility of errors. SMT pallets therefore improve overall manufacturing efficiency, decrease cycle times, and increase production throughput, which benefits both quality and cost-effectiveness.

Ensuring Component Placement Accuracy

One of the primary functions of SMT pallets is to ensure the precise positioning of PCBs during the component placement process. These pallets are meticulously engineered with tight tolerances and precise registration features that align seamlessly with automated pick-and-place machines. This ensures accurate component placement, even on high-density boards or when handling miniature components with fine pitch requirements. SMT pallets are essential for preserving the quality of the assembly process and reducing the possibility of placement errors, which enhances overall production reliability. They do this by offering consistent and dependable alignment.

Protecting PCBs During Production

Throughout the manufacturing process, PCBs undergo various stresses, such as mechanical handling, thermal cycling, and exposure to chemicals. SMT pallets serve as protective carriers, safeguarding the boards from potential damage. These pallets are often designed with raised edges, support structures, and cushioning features that prevent direct contact between the PCB and conveyor belts or other equipment. By reducing the possibility of scratches, warping, contamination, or static discharge, this design makes sure that the boards stay whole and retain their integrity during the whole assembly process.

Types and Applications of SMT Pallets

Single-Board Pallets

Single-board SMT pallets are specifically designed to hold individual PCBs securely, providing tailored support for each board. They are commonly used in prototyping, small-scale production, or when dealing with high-value or complex boards that require delicate handling. These pallets ensure maximum protection, preventing any potential damage during the manufacturing process. Their precise design makes them ideal for applications where accuracy and stringent quality control are essential, helping to maintain the integrity of each PCB throughout production.

Multi-Board Pallets

Multi-board SMT pallets are specifically designed to hold several PCBs at once, making them ideal for high-volume production environments. By enabling the simultaneous handling of multiple boards, these pallets significantly boost throughput and reduce production time. However, to maintain quality and precision, careful attention must be given to their design. Proper alignment and heat distribution are crucial to ensure consistent component placement and avoid potential defects, especially when working with boards that have complex layouts or varying component densities. This careful design ensures efficient and reliable production.

Customized Pallets for Unique Applications

In some cases, standard SMT pallets may not suffice for specialized PCB designs or unconventional manufacturing processes. Custom-designed pallets can be created to address specific challenges, such as:

- Accommodating odd-shaped or flexible PCBs

- Integrating additional features like RFID tags for traceability

- Incorporating removable sections for partial assembly or rework

- Designing pallets with built-in test points for in-line functional testing

These bespoke solutions ensure that even the most complex or unique PCB assemblies can be efficiently produced using SMT techniques.

Conclusion

SMT pallets are indispensable tools in modern electronics manufacturing, serving as the unsung heroes that enable the production of high-quality, reliable electronic devices. By providing stability, protection, and precise positioning for PCBs throughout the assembly process, these pallets contribute significantly to the efficiency and accuracy of SMT production lines. As electronics continue to evolve, with increasingly complex designs and miniaturization trends, the role of SMT pallets in ensuring manufacturing excellence will only grow in importance.

Contact Us

If you're looking to optimize your electronics manufacturing process or need custom SMT pallet solutions, don't hesitate to reach out to our team of experts. Contact us at info@jhd-material.com to learn how our 20+ years of experience in producing insulating sheets and materials can benefit your production needs.

References

1. Smith, J. (2022). "Advanced SMT Pallet Design for High-Density PCB Assembly"

2. Johnson, E. et al. (2021). "Materials Science in Electronics Manufacturing: The Role of SMT Fixtures"

3. Lee, S. K. (2023). "Optimizing SMT Production Lines: The Impact of Pallet Design on Throughput"

4. Thompson, R. (2020). "ESD Protection in Electronics Manufacturing: A Comprehensive Guide"

5. Garcia, M. and Chen, L. (2022). "Thermal Management in SMT Processes: Pallet Materials and Design Considerations"

6. Wilson, A. (2021). "Industry 4.0 in PCB Assembly: Smart Pallets and IoT Integration"