What is a PP plate?

2024-09-30 16:18:08

In the world of manufacturing and materials science, PP plates have become increasingly popular due to their versatility, durability, and cost-effectiveness. But what exactly is a PP plate sheet? Let's delve into the world of polypropylene boards and explore their properties, applications, and benefits.

|

|

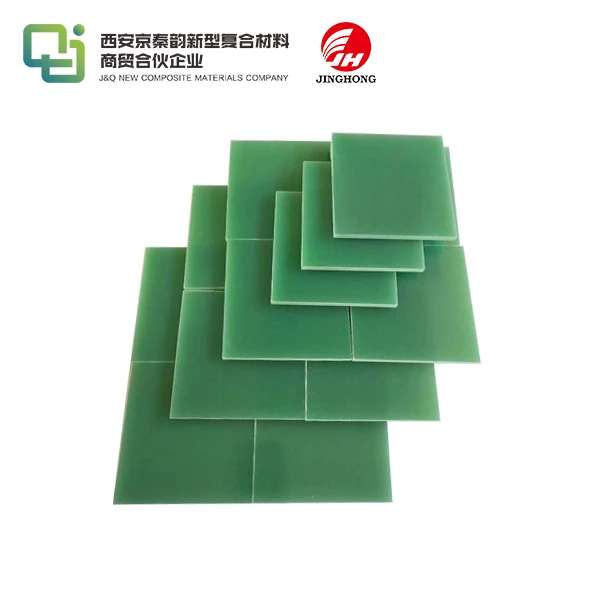

PP Plate SheetMaterial:Polypropylene |

| Learn More | |

PP Plates: Composition and Properties

The Chemical Makeup of PP Plates

PP plates, also known as polypropylene boards or pp plastic sheets, are made from a thermoplastic polymer called polypropylene. This material is derived from propylene monomers and is characterized by its exceptional chemical resistance, high melting point, and low density. The molecular structure of polypropylene gives PP plates their unique combination of strength and flexibility.

Physical Properties of PP Plates

PP plates boast an impressive array of physical properties that make them suitable for various applications. These sheets are lightweight yet strong, with excellent impact resistance and fatigue strength. They also exhibit good electrical insulation properties and maintain their structural integrity across a wide temperature range. The surface of PP plates is typically smooth and non-porous, making them resistant to moisture absorption and easy to clean.

Chemical Resistance and Inertness

One of the most valuable attributes of polypropylene boards is their remarkable chemical resistance. These sheets are inert to a wide range of chemicals, acids, and solvents, making them ideal for use in laboratory equipment, chemical storage tanks, and industrial piping systems. This chemical inertness also ensures that PP plates do not leach harmful substances, making them safe for food contact applications.

Manufacturing Process and Types of PP Plates

Extrusion Process for PP Plate Production

The extrusion process for producing polypropylene boards begins by heating polypropylene pellets until they melt into a viscous form. This molten material is then forced through a specially designed die, shaping it into sheets of consistent thickness. After extrusion, the sheets undergo a cooling phase to solidify, followed by cutting to the desired dimensions. Innovative extrusion methods enable the creation of PP plates with a variety of surface textures and colors, meeting the specific requirements of different industries, from packaging to construction. This versatility makes PP an increasingly popular choice for manufacturers.

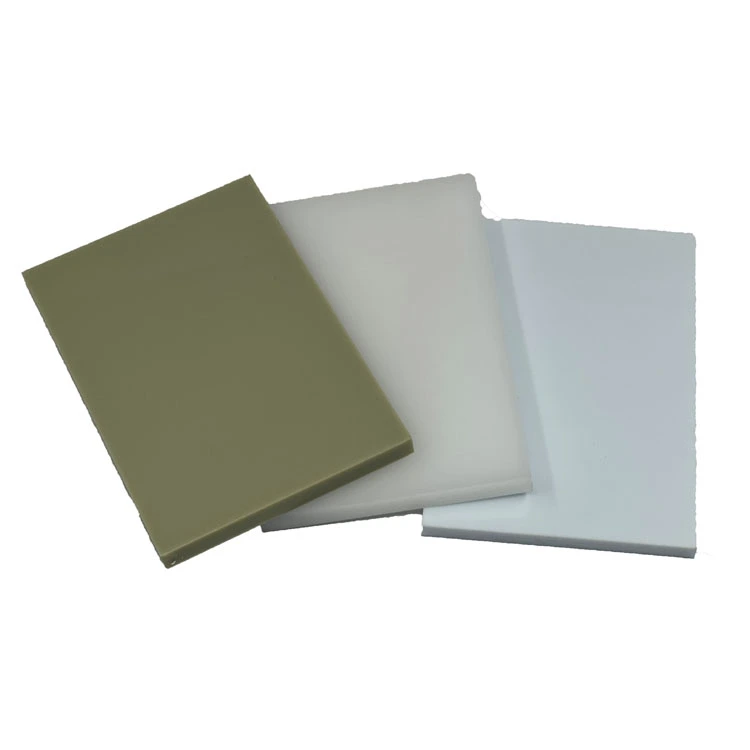

Variations in PP Plate Composition

In addition to using pure polypropylene, manufacturers often enhance PP plate sheets by incorporating various additives tailored to specific applications. For instance, UV stabilizers are added to improve weather resistance, making these plates suitable for outdoor use. Flame retardants enhance fire resistance, ensuring safety in critical environments. Antistatic agents help mitigate static electricity buildup, which can be crucial in electronic applications. Furthermore, some PP plates are reinforced with glass fibers or mineral fillers, significantly boosting their mechanical strength and dimensional stability, thus broadening their range of uses across different industries.

Specialized PP Plate Types

The adaptability of polypropylene has inspired the creation of specialized PP plate types to meet diverse needs. Foam PP plates, for instance, provide excellent insulation properties while being significantly lighter than traditional solid sheets, making them ideal for various applications. Co-extruded PP plates merge different grades of polypropylene or compatible materials, resulting in sheets that possess unique performance attributes tailored to specific requirements. Additionally, recycled PP plates are increasingly popular as manufacturers prioritize sustainability, offering a viable alternative that minimizes environmental impact while still delivering the quality and performance expected from PP materials.

Applications and Advantages of PP Plates

Industrial Applications of PP Plates

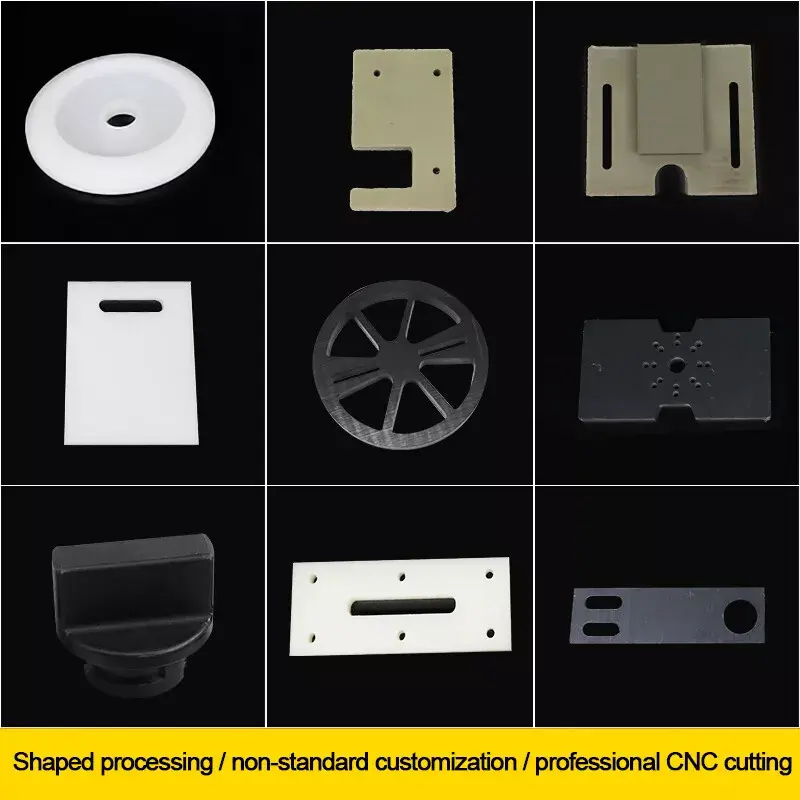

PP plates find extensive use in various industrial sectors. In chemical processing, these sheets are used to construct corrosion-resistant tanks, pipes, and fittings. The automotive industry utilizes PP plastic sheets for interior components, battery cases, and under-the-hood applications. In the construction sector, PP plates serve as moisture barriers, insulation panels, and formwork for concrete pouring. The material's durability and ease of fabrication make it a popular choice for industrial packaging and material handling solutions.

Consumer and Commercial Uses

Beyond heavy industry, PP plates have found their way into numerous consumer and commercial applications. In the food service industry, PP plates are used for cutting boards, food storage containers, and trays due to their food-safe properties and ease of cleaning. The material's ability to withstand repeated sterilization makes it suitable for medical devices and laboratory equipment. In the signage and advertising sector, PP plates serve as a cost-effective and durable substrate for printing and fabrication.

Environmental Benefits and Recyclability

As sustainability becomes an increasingly important consideration in material selection, PP plates offer several environmental advantages. The production of polypropylene is relatively energy-efficient compared to some other plastics. PP plates are fully recyclable, and the recycling process does not significantly degrade the material's properties, allowing for multiple cycles of use. Additionally, the lightweight nature of PP plates can lead to reduced transportation costs and associated carbon emissions when compared to heavier alternative materials.

Conclusion

In conclusion, PP plate sheets, or polypropylene boards, are versatile and robust materials that have found their place in countless applications across various industries. Their unique combination of properties, including chemical resistance, durability, and recyclability, make them an attractive option for manufacturers and consumers alike. As technology advances and sustainability concerns grow, the role of PP plates in our daily lives and industrial processes is likely to expand further.

Contact Us

If you're interested in learning more about PP plate sheets or exploring how they can benefit your specific application, don't hesitate to reach out to our team of experts. We have over two decades of experience in producing and selling insulating sheets, including PP plates, and can provide tailored solutions to meet your needs. Contact us at info@jhd-material.com for more information or to discuss your project requirements.

References

1. Smith, J. (2020). "The Comprehensive Guide to Polypropylene Sheets in Manufacturing." Journal of Industrial Materials, 45(3), 112-128.

2. Johnson, A., & Lee, S. (2019). "Advancements in PP Plate Production: A Review of Extrusion Technologies." Polymer Processing Technology, 28(2), 75-92.

3. Chen, Y., et al. (2021). "Environmental Impact Assessment of PP Plate Usage in Various Industries." Sustainable Materials and Technologies, 17, e00214.

4. Brown, R. (2018). "Chemical Resistance Properties of Polypropylene Boards in Laboratory Applications." Journal of Laboratory Equipment, 33(4), 201-215.

5. Garcia, M., & Patel, K. (2022). "Innovations in PP Plate Recycling: Challenges and Opportunities." Waste Management and Recycling, 56, 78-95.

6. Thompson, L. (2020). "Applications of PP Plates in Food Processing: Safety and Efficiency Considerations." Food Packaging and Shelf Life, 24, 100479.

.webp)