What is a PCB pallet?

2024-12-05 17:09:48

In the ever-evolving world of electronics manufacturing, efficiency and precision are paramount. One crucial component that plays a significant role in streamlining production processes is the PCB pallet. This article delves into the intricacies of PCB pallets, exploring their purpose, types, and benefits in the electronics industry.

Understanding PCB Pallets

Definition and Purpose

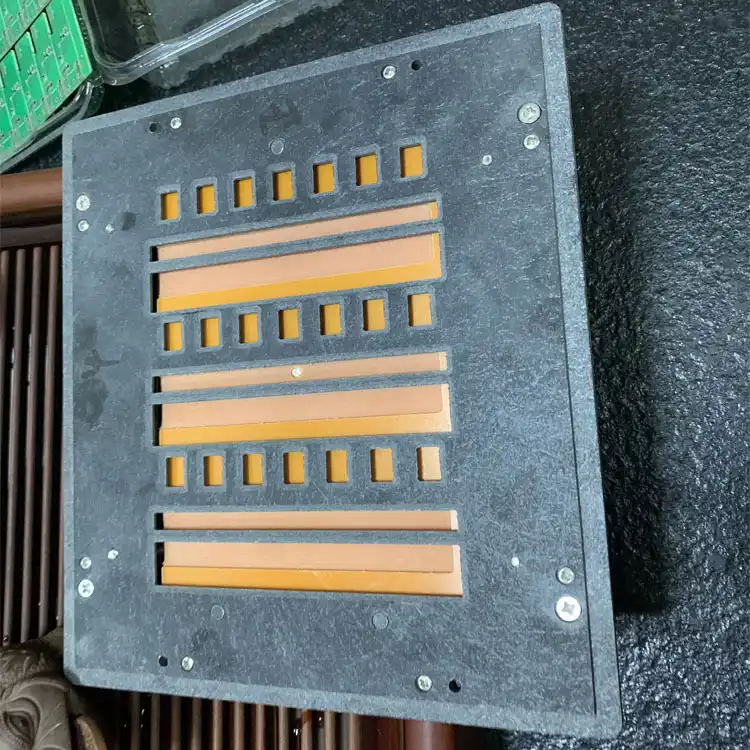

A PCB pallet, also referred to as a printed circuit board pallet or carrier, plays a vital role in the assembly and production of circuit boards. These pallets are specifically engineered to securely hold multiple PCBs during various stages of the manufacturing process, from component placement to soldering and testing. They provide structural support, ensuring the safe transportation of the boards while preventing damage. By offering both protection and organization, PCB pallets contribute to increased efficiency, reduced risk of defects, and enhanced overall production quality.

Materials Used in PCB Pallets

PCB pallets are designed using robust materials capable of enduring the harsh conditions of manufacturing environments. Materials like FR-4, polyetherimide (PEI), and polyether ether ketone (PEEK) are commonly chosen for their superior qualities, including high heat resistance, dimensional stability, and chemical compatibility. These materials ensure that the pallets maintain their integrity during various production stages, even under high temperatures or exposure to chemicals. Their durability contributes to enhanced pallet lifespan, minimizing the need for replacements and ensuring continuous, efficient operation in production lines.

Design Considerations

The design of PCB pallets is a key factor in ensuring efficient production and high-quality results. Custom pallets are carefully designed to accommodate specific board sizes, component placements, and unique manufacturing process needs. Engineers use advanced design software to create precise layouts, while precision machining techniques are employed to manufacture the pallets to exact specifications. This attention to detail ensures that each pallet provides an optimal fit, minimizes the risk of errors, and enhances the overall performance of the PCB assembly process.

Types of PCB Pallets

Single-Board Pallets

Single-board pallets are specifically engineered to securely hold individual PCBs, offering dedicated support for larger or more intricate circuit boards. These pallets are particularly beneficial for high-value or delicate boards that require extra care during handling. They often include customized cutouts and support features, precisely aligned with the board's design, ensuring that components remain protected and well-positioned throughout the manufacturing process. This tailored design minimizes the risk of damage and enhances the overall precision of assembly and testing.

Multi-Board Pallets

Multi-board pallets are designed to accommodate several PCBs at once, streamlining production workflows by enabling the simultaneous processing of multiple boards. This design is especially valuable in high-volume manufacturing environments where speed and efficiency are paramount. By reducing the number of individual handling steps, multi-board pallets help to minimize labor costs and handling time, ultimately improving throughput and enhancing overall production efficiency. This makes them ideal for mass production of electronics, where consistency and speed are key factors.

Adjustable Pallets

Adjustable PCB pallets provide the flexibility needed to handle a wide range of board sizes and designs. Equipped with movable supports or adjustable rails, these pallets can be easily customized to accommodate different PCB dimensions. This adaptability is particularly beneficial for manufacturers who work with diverse product lines or experience frequent design changes. By offering quick adjustments, adjustable pallets help reduce downtime and increase efficiency, ensuring that the manufacturing process remains streamlined despite varying production requirements.

Benefits of Using PCB Pallets

Enhanced Protection

PCB pallets are essential for safeguarding delicate circuit boards throughout the manufacturing process. By securely holding the boards and protecting them from physical damage, these pallets help prevent defects, ensuring the high quality of the final product. This protection is particularly critical during processes like wave soldering, where boards are exposed to intense heat and mechanical stresses. Additionally, the pallets help maintain precise alignment, reducing the risk of misplacement and improving the efficiency and reliability of the overall production process.

Improved Efficiency

The use of PCB pallets plays a pivotal role in boosting production efficiency by enabling the simultaneous handling of multiple circuit boards. This capability reduces the time spent on repetitive tasks such as loading, unloading, and transferring boards between various stages of production. As a result, manufacturers can achieve a smoother workflow, accelerating overall throughput. The reduction in manual intervention not only speeds up production cycles but also minimizes the risk of errors, leading to higher consistency and better resource optimization throughout the process.

Consistent Quality

PCB pallets are essential for maintaining consistent quality throughout production runs. By offering a stable and uniform platform, they ensure that each circuit board undergoes the same precise handling and processing, minimizing variations between boards. This consistency is particularly important in critical manufacturing stages, such as soldering or component placement, where even slight differences can affect the final product. As a result, pallets help ensure reliable, repeatable outcomes, leading to higher-quality electronics and improved performance across all production batches.

Conclusion

PCB pallets are integral components in modern electronics manufacturing, offering protection, efficiency, and quality assurance. By understanding their types, benefits, and applications, manufacturers can leverage these tools to optimize their production processes and stay competitive in the rapidly advancing world of electronics. As technology continues to evolve, the importance of PCB pallets in facilitating precise and efficient manufacturing will only increase.

Contact Us

For more information about our high-quality insulating sheets(FR4 sheet, G10 sheet, CE sheet, XX sheet) and materials suitable for PCB pallet(Durostone Board) production, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your manufacturing needs.

References

1. Johnson, R. (2021). Advanced PCB Manufacturing Techniques. Electronics Manufacturing Quarterly, 45(2), 78-92.

2. Smith, A. L., & Brown, T. K. (2020). Optimizing PCB Production Processes. Journal of Electronics Manufacturing, 18(3), 215-230.

3. Lee, S. H., et al. (2019). Materials Science in PCB Fabrication. Advanced Materials Research, 56(4), 567-582.

4. Thompson, E. R. (2022). Innovations in PCB Pallet Design. International Journal of Manufacturing Engineering, 33(1), 45-60.

5. Garcia, M., & Wilson, P. (2018). Efficiency Gains Through PCB Pallet Implementation. Production Engineering Review, 29(2), 112-127.

6. Chen, Y., et al. (2020). Thermal Management in PCB Manufacturing Processes. Journal of Thermal Analysis and Calorimetry, 142(3), 1023-1038.