What are the properties of Bakelite Sheets?

2024-05-08 15:36:23

Introduction

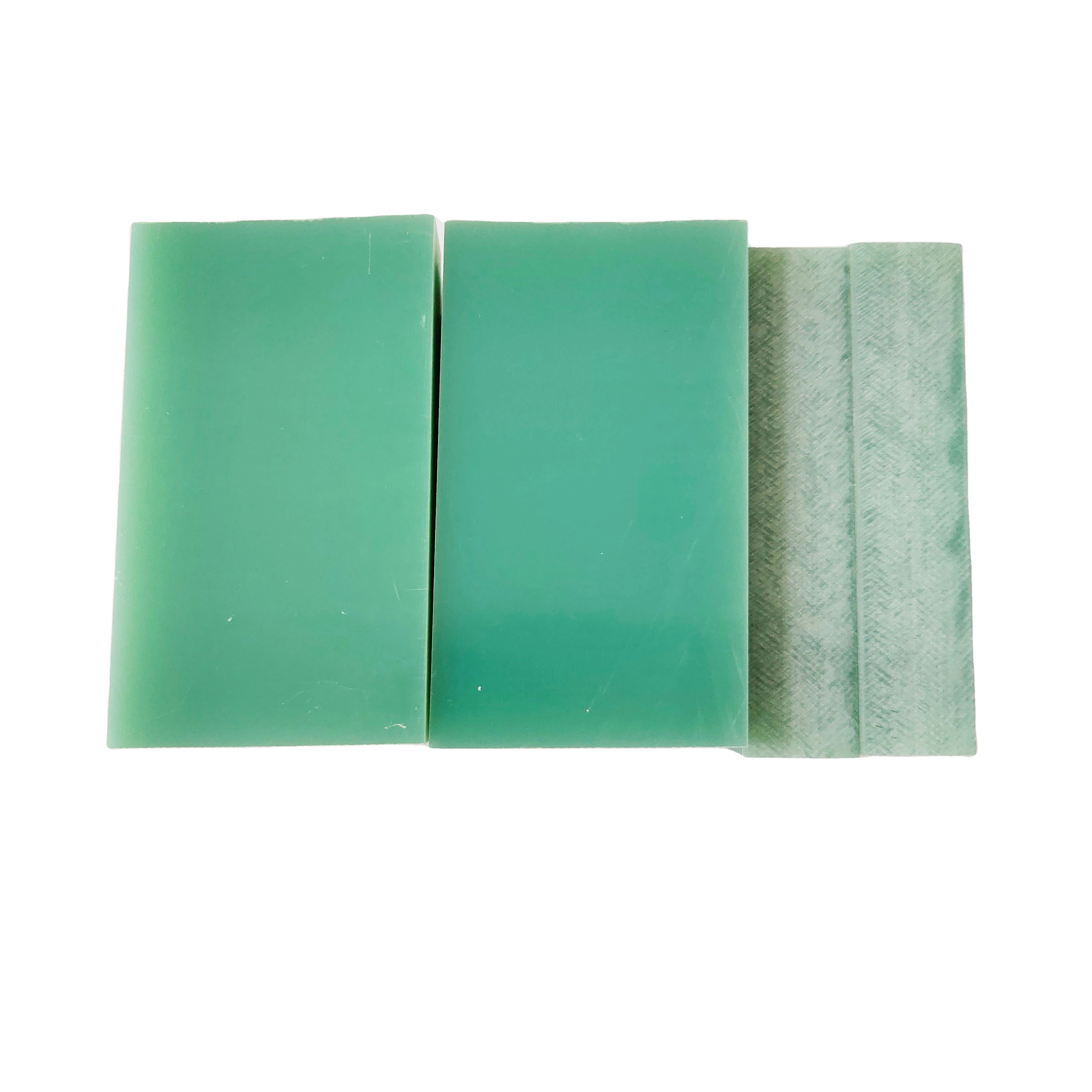

Bakelite sheets have long been integral to industrial applications, embodying a legacy of innovation and reliability. As we embark on an exploration of their properties, it becomes evident that sheets occupy a unique position in the realm of materials engineering. In this presentation, we set the organize for our examination, shedding light on the noteworthiness of sheets and the urgent part they play in different mechanical segments. From their inception to their modern-day applications, sheets continue to exemplify durability, versatility, and resilience. Join us as we unravel the distinct properties that make sheets indispensable in the world of manufacturing and engineering.

Composition of The Sheets

The sheets derive their unique properties from a precise composition crafted through meticulous engineering. Comprising phenol formaldehyde resin as the primary component, sheets are reinforced with fillers to enhance their mechanical and thermal properties. The composition typically involves a combination of phenol and formaldehyde, which undergo a polymerization reaction under controlled conditions to form a thermosetting plastic resin. This resin matrix is then reinforced with fillers such as cellulose fibers, cotton, or asbestos to impart strength, rigidity, and dimensional stability to the sheets.

The phenol formaldehyde resin serves as the binder, binding the fillers together and providing the matrix with its inherent properties. Phenol formaldehyde resins are renowned for their excellent electrical insulation properties, chemical resistance, and high heat tolerance, making them ideal for applications where reliability and performance are paramount.

The choice and proportion of fillers play a crucial role in determining the specific characteristics of sheets. For instance, the incorporation of cellulose fibers enhances the tensile strength and impact resistance of sheets, while asbestos fillers contribute to their exceptional heat resistance. The precise formulation of sheets can be tailored to meet the requirements of diverse applications, ranging from electrical insulation to structural components in automotive and aerospace industries.

In summary, the composition of sheets comprises phenol formaldehyde resin as the base matrix reinforced with fillers, resulting in a material renowned for its robustness, versatility, and enduring performance across a spectrum of industrial applications.

Electrical Insulation Properties

Among the hallmark properties of sheets is their exceptional electrical insulation prowess. We embark on a discussion elucidating sheets' high dielectric strength and unparalleled resistance to electrical conductivity. Additionally, compelling data and statistics underscore Bakelite's prowess as an electrical insulator, showcasing its efficacy in diverse applications.

Thermal Stability

The exploration extends to sheets' remarkable thermal stability, a cornerstone of their utility in industrial settings. Delve into examples illuminating the criticality of sheets' thermal stability, underscoring their ability to withstand soaring temperatures sans deformation or degradation.

Mechanical Strength and Durability

In this section, we scrutinize sheets' mechanical properties, including strength, stiffness, and impact resistance. Drawing from an array of case studies, we unveil the resilience of sheets across varied industrial landscapes, highlighting their steadfast durability.

Chemical Resistance

Bakelite sheets emerge as formidable contenders in environments fraught with chemical hazards, owing to their robust resistance to chemicals and corrosion. We delineate scenarios across industries where sheets' chemical resistance proves instrumental, safeguarding critical components from corrosive onslaughts.

Dimensional Stability

The discourse navigates towards sheets' unwavering dimensional stability, an attribute paramount in precision-centric manufacturing and engineering applications. Unveil the practical implications of sheets' dimensional stability, elucidating their role in ensuring operational integrity under diverse conditions.

Surface Finish and Aesthetic Properties

Surface finish emerges as a pivotal facet of sheets, dictating not only their visual appeal but also their functional efficacy. We embark on an exploration of sheets' surface finish options, accentuating their diverse aesthetic properties and the pivotal role they play in augmenting functionality.

Environmental Considerations

This section traverses the terrain of environmental considerations pertinent to sheets, encapsulating discussions on sustainability, recycling initiatives, and responsible disposal practices. Delve into the concerted efforts aimed at mitigating the environmental footprint of Bakelite production and utilization.

Conclusion

In conclusion, the properties of sheets underscore their remarkable utility and resilience across a wide array of industrial applications. From their inception as the first synthetic plastic to their modern-day use in cutting-edge engineering projects, sheets have stood the test of time as a testament to human ingenuity and innovation.

The composition of sheets, featuring phenol formaldehyde resin reinforced with fillers, imbues them with a unique combination of properties. Their exceptional electrical insulation properties, thermal stability, mechanical strength, and chemical resistance make them indispensable in sectors ranging from electrical engineering to automotive manufacturing.

Moreover, sheets' dimensional stability, surface finish options, and environmental considerations further enhance their appeal and suitability for diverse applications. As industries continue to evolve and innovate, sheets remain a stalwart choice for engineers and manufacturers seeking reliable, high-performance materials.

In light of their enduring legacy and proven track record, sheets continue to play a pivotal role in shaping the landscape of modern manufacturing and engineering. Whether it's providing electrical insulation in critical infrastructure or serving as structural components in aerospace applications, sheets exemplify durability, versatility, and innovation.

As we look to the future, the properties of sheets will undoubtedly continue to drive advancements in technology and industry. With their unmatched combination of properties and proven performance, sheets remain a cornerstone of materials engineering, paving the way for progress and innovation in the years to come.

Contact us

Looking for a reliable supplier of Bakelite sheets? Look no further! We are a professional manufacturing supplier, equipped with a GMP-certified facility and an extensive inventory. With a comprehensive range of certifications, we ensure the highest quality standards in every product we deliver.

Partner with us for your OEM needs, and experience our swift delivery and meticulous packaging. We prioritize your satisfaction and offer support throughout the procurement process. Whether you require customized solutions or standardized products, we've got you covered.

For inquiries and collaboration opportunities, reach out to us at info@jhd-material.com. Let's work together to elevate your projects with top-notch Bakelite solutions.

References

- Bakelite: The Plastic That Made History. (n.d.). Retrieved from https://www.bakelite.com/history.html

- Henschke, T. (2018). Understanding Bakelite as a Material. Industrial Plastic Products & Shapes. Retrieved from https://www.iplasticsupply.com/blog/understanding-bakelite-as-a-material

- Knappe, J. (2020). Bakelite - The Material of a Thousand Uses. Science History Institute. Retrieved from https://www.sciencehistory.org/distillations/bakelite-the-material-of-a-thousand-uses

- Bakelite Sheet Properties & Applications. (n.d.). Redwood Plastics and Rubber. Retrieved from https://www.redwoodplastics.com/plastic-sheet/bakelite-sheet-properties-applications/

- Bakelite: Properties and Uses. (n.d.). Thomasnet. Retrieved from https://www.thomasnet.com/articles/plastics-rubber/bakelit

.webp)