What are the main uses of epoxy resin?

2023-10-11

Liquid Epoxy resin is a type of polymer with a molecular formula of (C11H12O3)n, which refers to a general term for polymers that contain two or more epoxy groups in their molecules. It is a thermosetting resin that is the condensation product of epichlorohydrin and bisphenol A or polyols. Due to the chemical reactivity of the epoxy group, it can be opened by various compounds containing active hydrogen, cured, and crosslinked to form a network structure, making it a thermosetting resin. Bisphenol A epoxy resin not only has the largest production volume and the most complete variety, but also continues to increase in new modified varieties with improving quality.

The excellent physical, mechanical, and electrical insulation properties of epoxy resin, its adhesive properties to various materials, and the flexibility in its processing techniques are unmatched by other thermosetting plastics. Therefore, it is widely used in various fields of the national economy as coatings, composite materials, casting materials, adhesives, molding materials, and injection molding materials.

Liquid Epoxy resin has been widely used in fields such as adhesives, coatings, composite materials, electronics, and motors, and it has three main advantages:

1. Epoxy resin has low curing shrinkage and good dimensional stability.

2. Epoxy resin has stable chemical properties and is not easily corroded or damaged by common acids, alkalis, chemicals, and industrial solvents.

3. Epoxy resin has excellent adhesion to many materials, high mechanical strength, and can withstand long-term environmental stress, making it highly reliable.

In fact, the greatest advantage of epoxy resin is its variability. By adjusting the composition formula, it can quickly cure or remain unreactive for a long time. It can be transformed into rigid adhesives or highly flexible materials.

Methods for toughening and modifying epoxy resin:

Epoxy resin (EP) is a very important thermosetting resin, which is formed by the reaction of EP oligomers and curing agents. It is generally divided into five categories according to the chemical structure and the binding mode of the EP base: aliphatic amine, aliphatic ester, aliphatic ether, aliphatic cyclic, and aromatic cyclic epoxy compounds.

Due to the large number of EP groups in pure EP, the high chemical cross-linking density of the cured structure, low flexibility of molecular chains, and high internal stress, the cured EP material has higher brittleness, poor impact resistance and fatigue durability, which limits its application and development in some high-tech fields with high requirements for durability and reliability. Therefore, it is necessary to toughen and modify EP while maintaining its excellent properties.

Currently, there are three main ways to toughen and modify EP in the industry:

(1) Add rubber elastomers, core-shell polymers, thermoplastic resins (TP), thermotropic liquid crystal polymers (TLCP), and nano-particles to the EP matrix to form micro-phase separation or homogeneous structure;

(2) Continuously thread TP in the EP three-dimensional cross-linking network to form an interpenetrating network structure for toughening;

(3) Adjust the microstructure of EP, such as introducing more flexible chain segments in the three-dimensional cross-linking network to improve its molecular flexibility, or introducing a micro-phase separation structure to enhance the deformation synergy of molecular chain segments, achieving toughening.

Application of Epoxy Resin in Coatings

Epoxy resin has a large proportion of applications in coatings, and can be made into various varieties with distinctive features and uses. Its common characteristics include: (1) excellent chemical resistance, especially alkali resistance; (2) strong adhesion to paint film, especially to metal; (3) good heat resistance and electrical insulation properties; (4) good color retention of the paint film.

However, the weather resistance of bisphenol A type epoxy resin coatings is poor, and the paint film is prone to chalking and losing its gloss outdoors, making it unsuitable for outdoor use and high decorative coatings. Therefore, epoxy resin coatings are mainly used as anticorrosive paints, metal primers, and insulating paints, but coatings made of heterocyclic and aliphatic epoxy resins can be used for outdoor applications.

Applied to automobiles: chassis primer, component paint, tank truck interior coating.

Applied to containers: food can interior and exterior coatings, storage tank interior and exterior anti-corrosion coatings, pressure vessel anti-corrosion coatings.

Applied to factory equipment: equipment and pipeline anti-corrosion coatings, refrigerator, washing machine outer layer coatings, electrical equipment insulation coatings.

Applied to civil construction: bridge anti-corrosion coatings, steel structure anti-corrosion coatings, waterborne product anti-seepage coatings, floor coatings, decorative coatings, functional coatings, steel wire mesh cement gates.

Applied to ships: hold interior coatings, sea container coatings, steel component anti-corrosion coatings.

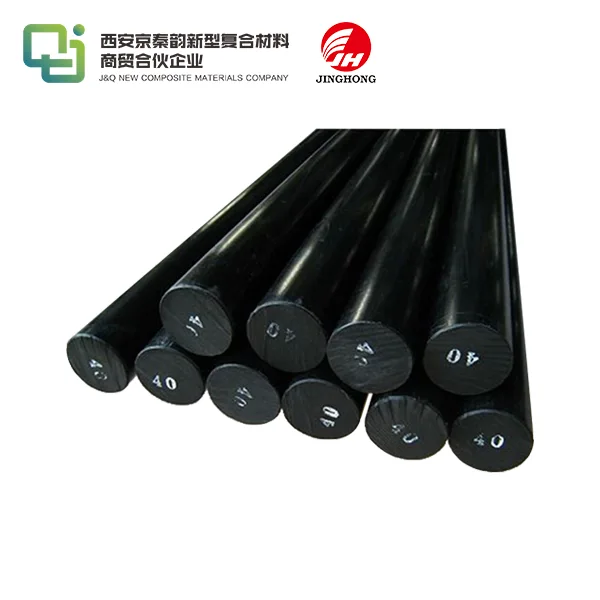

Clear Epoxy Resin in Composite Materials

Epoxy engineering plastics mainly include epoxy molding plastics and epoxy laminated plastics used for high-pressure molding, as well as epoxy foam plastics. Epoxy engineering plastics can also be regarded as a kind of broad-spectrum epoxy composite material. Epoxy composite materials mainly include epoxy fiberglass reinforced plastic (universal composite material) and epoxy structural composite materials, such as extruded epoxy profiles, hollow rotary molded products, and high-performance composite materials. Epoxy composite materials are an important structural and functional material in high-tech fields such as chemical industry, aviation, aerospace, and military.

Epoxy resin engineering plastics are mainly used as engineering plastic parts that require high strength, good impact toughness, and certain heat resistance. Examples include rocket tail fins, armor-piercing bullet supports, sonar fins, etc. They are also used as functional plastics, such as encapsulating materials for electronic components, water-lubricated plastic bearings, etc. High-performance epoxy composite materials are mainly used as structural components for aircraft, satellites, spacecraft, solid rocket engine shells, and high-end sports equipment such as tennis rackets, balls, fishing rods, and rowing boats.

Applied to automobiles: fiberglass car shells, fiberglass floors, fiberglass tank trucks, control system instruments and electrical components, displays, automotive dry ignition coils, fiberglass parts, anti-slip granule steering wheel covers, epoxy resin local reinforcement materials.

Applied to sports equipment: fiberglass safety helmets, rackets, golf clubs, fishing rods, bowling balls, snow shovels, surfboards, fiberglass rowing boats, sailboats, racing cars, lounge chairs, hockey sticks.

Applied to other fields: aircraft fuselages, helicopter rotor blades, wind turbine blades, medical instruments, surgical knife handles, pacemakers, handicrafts and jewelry, valve seals, hydraulic engineering projects, field emission screens, concrete wear-resistant layers, insulation materials, animal models, aerospace vehicles, marine stern shafts, rudder shafts, chemically treated wood, tower reinforcement, maglev train tracks, solar cells, musical instruments, epoxy decorations, fiberglass tent poles, knife handles, windows, furniture, pumps, canes, graphics cards, infrared filters, digital displays, matrix radiators, light-emitting diodes and photodiodes, laboratory countertops, simulated trees, prefabricated grinding stones, road and bridge pavements, etc.

Epoxy Resin Adhesive

Epoxy resin adhesive is an engineering adhesive composed of epoxy resin base materials, curing agents, diluents, accelerators, and fillers. Due to its good adhesive properties, functionality, relatively low price, and simple bonding process, it has become an indispensable material in fields such as aircraft, missiles, rockets, satellites, automobiles, ships, machinery, electronics, and civil construction in recent decades.

In addition to poor adhesion to non-polar plastics such as polyolefins, epoxy resin has excellent adhesive properties for various metal materials such as aluminum, steel, iron, copper; non-metallic materials such as glass, wood, concrete; and thermosetting plastics such as phenolic, amino, unsaturated polyester, making it known as the universal adhesive. Epoxy adhesives are an important type of structural adhesive.

Epoxy resin adhesives for civil construction conform to the general trend of modern civil construction development, so they have developed rapidly in the past decade. Epoxy adhesives have been widely used in the aerospace industry, mainly in the manufacturing of honeycomb sandwich structures, fully bonded sheet metal structures, composite metal structures, and metal-polymer composite materials. Its application has become one of the foundations of aircraft design.

In the electrical industry, epoxy adhesives are used for insulation fixation in the slots of electric motor cores, bonding of silicon steel sheets in transformers, and bonding of iron cores and phase shifters for long-distance transmission of three-phase currents in electron accelerators.

Currently, epoxy resin adhesives are more widely used in the electronics and electrical fields due to their excellent comprehensive performance, particularly outstanding insulation performance. However, in the fields of electronics, electrical engineering, and structural bonding, stricter requirements have been proposed in the market, including rapid curing and oil surface bonding. Therefore, epoxy resin adhesives must be continuously modified to meet various application requirements and continue to develop.

拷贝.webp)