What are the benefits of FR4?

2024-07-04 14:55:31

Introduction

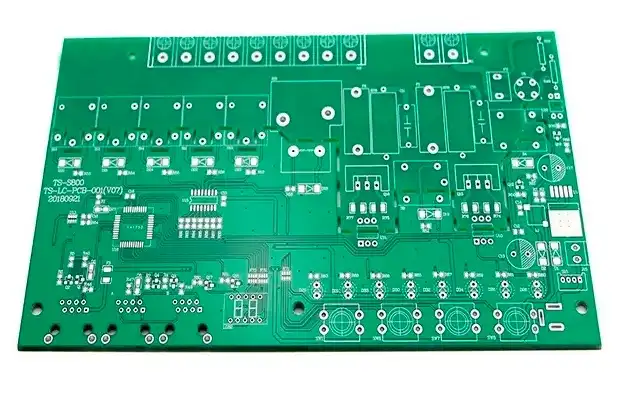

FR4 is a for the most part seen and involved epoxy material that fills in as the spine for printed circuit sheets (PCBs) in the equipment business. Due to its unique combination of mechanical strength, electrical insulation properties, and affordability, it is the choice for many electronic applications. Specialists and fashioners who need to create electronic gadgets that can endure various functional burdens and ecological circumstances should have a strong comprehension of these advantages. The specific properties of FR4 epoxy and the ways in which it enhances PCB performance and durability are detailed in this article, which delves into the numerous benefits of FR4.

FR4 and other PCB materials will also be compared, with a focus on the distinguishing features that set it apart. This includes looking at its dielectric properties, thermal stability, and moisture resistance, all of which help explain why it is used so much. By investigating these perspectives, we want to give a complete outline that exhibits why FR4 is as yet a major part in the creation of gadgets and makes it workable for innovation and development to progress. Whether you're an expert in the field or just a fan, learning about the benefits of FR4 will give you the information you need to make informed decisions about PCB design and material selection.

Why is FR4 used in PCBs?

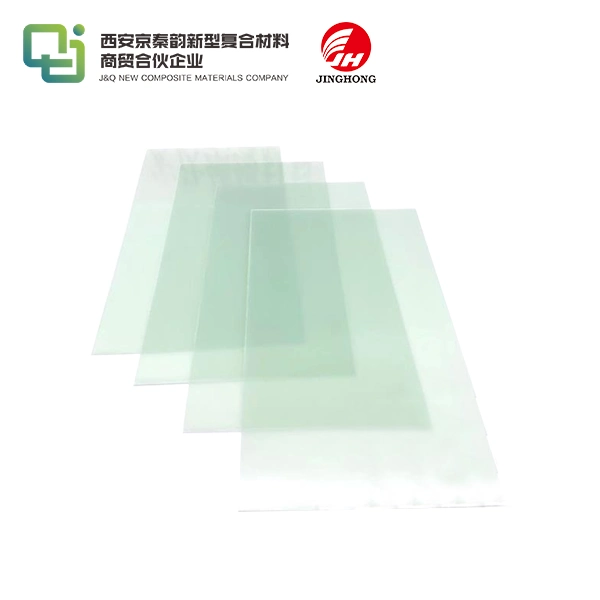

Flame Retardant 4, also known as FR4, stands out because it is a composite material made of woven fiberglass cloth that has been coated with an epoxy resin binder. This blend is carefully designed to satisfy severe prerequisites for electrical protection, mechanical strength, and warm soundness fundamental in the domain of PCB applications. The usage of FR4 epoxy in PCB fabricating is supported by a few convincing reasons that highlight its broad reception and strength in the business.

- Extraordinary Electrical Protection: One of the essential variables driving the commonness of FR4 in PCBs is its noteworthy electrical protection properties. By successfully forestalling current spillage, FR4 guarantees the trustworthiness and security of signs sent across the PCB, consequently reinforcing the dependability and execution of electronic circuits.

- Mechanical Stain Resistance: PCBs are highly durable and resilient in the face of physical stress and environmental influences thanks to FR4's composition, which is supported by fiberglass reinforcement. This vigor is critical in guaranteeing the supported usefulness and life span of electronic gadgets across assorted functional circumstances.

- Prevalent Warm Opposition: The epoxy tars incorporated inside FR4 give estimable warm protection from the material, empowering PCBs to keep up with functional viability across an expansive range of temperatures without capitulating to huge corruption. Electronic systems' performance and dependability are maintained by this thermal resilience in a variety of thermal environments.

These features combine to make FR4 a material that is extremely adaptable and dependable, making it suitable for a wide range of applications, from consumer electronics to industrial equipment, where unwavering performance and durability are essential requirements. As a result, the inherent characteristics of FR4 not only enhance the quality and dependability of PCB manufacturing but also contribute to the smooth operation of electronic devices.

What are the electrical properties of FR4?

Notwithstanding its prominent mechanical and warm properties, FR4 shows explicit electrical attributes that essentially improve its reasonableness for PCB plan:

- Dielectric Constant: The stable and observable dielectric constant of FR4 sets it apart from other materials because it is essential for ensuring consistent electrical performance throughout circuits. Supporting the integrity of electronic transmissions, the dependable dielectric constant of FR4 enables the precise control of signal propagation and impedance matching.

- Scattering Variable: One more key electrical quality of FR4 is its low dispersal factor, which adds to negligible energy misfortune as electrical signs cross through the PCB. Because it reduces energy loss in the form of heat or other forms, this property is crucial to the effective operation of electronic devices.

- Impedance Control: FR4 offers the upside of empowering exact command over impedance, a basic element especially significant in fast computerized and simple circuits. The capacity to oversee impedance really considers the moderation of sign mutilation, guaranteeing ideal sign uprightness and dependability in different electronic applications.

Applications that require high-frequency performance, such as those in the telecommunications, aerospace, and medical electronics industries, can benefit greatly from FR4's exceptional electrical properties. These properties point to the crucial role that FR4 Epoxy Board plays in ensuring the functionality and dependability of cutting-edge electronic systems in harsh environments.

How does FR4 compare to other PCB materials?

While looking at PCB materials, it is essential to consider the qualities and properties of FR4 according to options like PTFE (Polytetrafluoroethylene) or earthenware substrates. This assessment takes into consideration a far reaching comprehension of the benefits and disservices of every material.

- Cost-effectiveness: FR4 is known for its expense viability, pursuing it a famous decision for efficiently manufactured purchaser gadgets. FR4 is typically less expensive than materials like PTFE and ceramics, which can have a significant impact on the overall cost of making electronic devices. FR4 is an appealing option for applications where budget constraints are a concern due to its cost advantage.

- Recurrence Execution: High-frequency performance is one area in which PTFE performs better than FR4. When compared to FR4, PTFE has a lower loss tangent and dielectric constant, resulting in improved signal integrity at higher frequencies. Because of this property, PTFE is the best material for high-frequency signal transmission and reception applications like radar technologies and wireless communication systems.

- Warm Administration: Ceramic substrates perform better than FR4 when it comes to heat dissipation and thermal conductivity. Clay materials have incredible warm conductivity, considering effective intensity move and dissemination. Ceramics are particularly well-suited for power electronics applications that generate a lot of heat during operation due to this property. Conversely, FR4 has moderate warm conductivity, which might restrict its utilization in high-power applications where successful warm administration is essential.

FR4 is still the most commonly used material for standard PCBs, despite the advantages that PTFE and ceramics offer in some respects. This is primarily because the majority of electronic applications require a well-balanced combination of electrical, mechanical, and thermal properties. FR4 Epoxy Board has acceptable thermal properties, good mechanical strength and flexibility, and satisfactory performance across a wide frequency range. These qualities settle on FR4 a flexible and solid decision for different enterprises, including media communications, car, aviation, and shopper hardware.

In conclusion, FR4's cost-effectiveness, overall electrical performance, mechanical strength, and thermal properties make it the preferred choice for many applications, while alternatives like PTFE and ceramics offer superior performance in particular areas. The particular requirements and constraints of the project at hand ultimately determine the selection of the appropriate PCB material.

Conclusion

In conclusion, the excellent electrical insulation, mechanical toughness, and thermal stability of FR4 epoxy highlight its advantages in PCB manufacturing. Not only do these properties make electronic devices reliable, but they also make production more cost-effective. Understanding how FR4 analyzes to other PCB materials helps in settling on informed choices in regards to material determination in view of explicit application needs.

References

1. "FR-4 (FR4) Glass Epoxy Sheet Material | CTE-Laminate.com"

2. "Why is FR-4 the Most Popular PCB Material? | Royal Circuits"

3. "FR4 PCB Material | What is FR-4? | 4pcb.com"

4. "Understanding FR-4 Material for PCB Design | Sierra Circuits"

5. "FR-4 PCB Materials | Waveroom Plus"

6. "The Differences Between PTFE and FR4 PCB Materials | Epec Engineering"

7. "PCB Material Selection Guide | PCBCart"

8. "FR4 Material Properties | PCB Universe"

9. "Comparison of PCB Substrate Materials | Electronic Design"

10. "Choosing the Right PCB Substrate | Altium Blog"